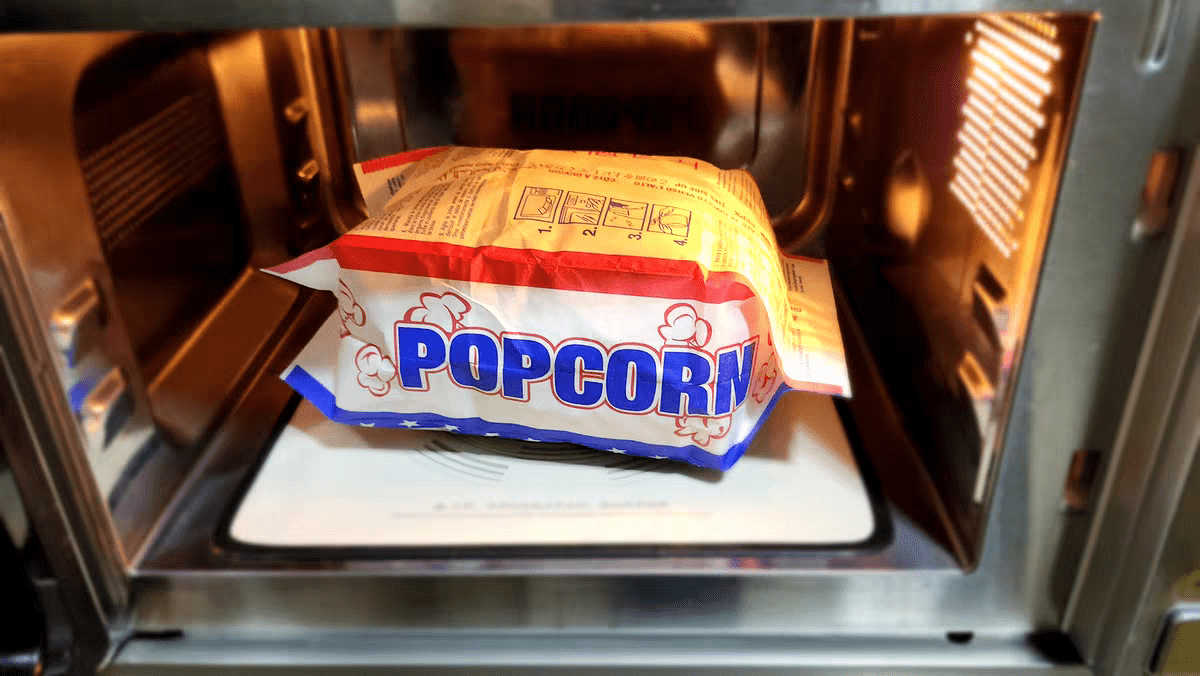

Do you know how to make Microwave Popcorn Bag,how many machines do I need?

- One stop solution

Description

Complete Equipment List for Microwave Popcorn Bag Production

If you're planning to start or upgrade a microwave popcorn bag production line, choosing the right equipment is crucial. The following machines are essential for creating multi-layer laminated popcorn bags that are safe for microwave use, visually appealing, and compliant with food-grade packaging standards.

1. Lamination Machine for Popcorn Bags

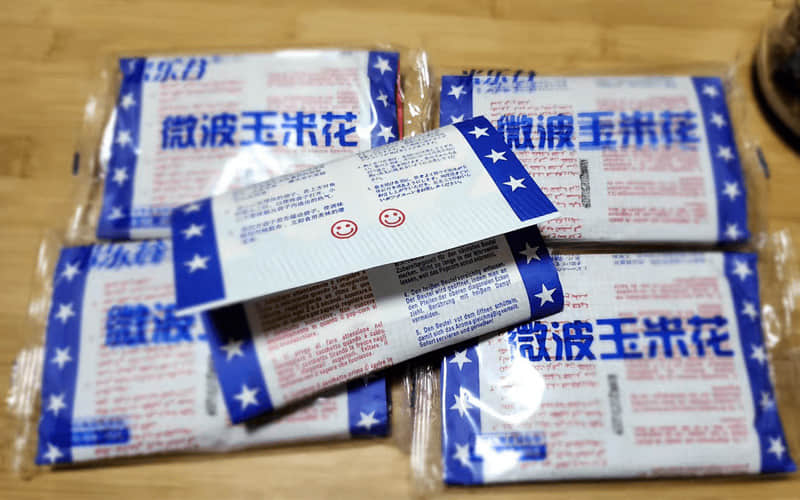

A high-quality lamination machine is used to bond multiple layers such as kraft paper, PET film, aluminum foil (Alu), and polyethylene (PE) or polypropylene (PP) to form a strong, heat-resistant structure. This multi-layer lamination improves both the durability and the heat insulation of microwaveable popcorn bags. The process is essential for popcorn bag lamination and ensures excellent barrier properties for extended shelf life.

2. Flexographic or Gravure Printing Machine

To make your product stand out, a flexographic printing machine or gravure printing machine is used to print high-resolution graphics and branding on the outer surface of the bag. This equipment supports various food-safe inks and allows for food-grade printing on laminated film. It is an integral part of popcorn packaging printing, ensuring colorful, attractive designs suitable for retail shelves.

3. Hot Sealing & Gluing System

A high-performance hot melt sealing system is essential for bonding the bag’s edges. It uses heat or glue to create secure seals that prevent leakage or bursting during heating. This popcorn bag gluing machine ensures precise sealing that is strong enough to withstand microwave pressure, making it a key step in microwave popcorn packaging.

4. Susceptor Placement Machine

Microwave popcorn bags require a microwave susceptor film, which converts microwave energy into heat for even popcorn popping. The susceptor placement machine accurately applies metallized film to the inner surface of each bag. This susceptor positioning step ensures optimal cooking performance and safety in every batch.

5. Bag Cutting and Converting Machine

This is the core of the production line—a specialized popcorn bag folding machine that folds and forms the bag into the correct structure. It supports Z-fold designs, gusset forming, and side sealing, ensuring each popcorn pouch is uniform and ready for filling. The Z-fold popcorn bag machine ensures that bags remain flat for packaging and expand properly in the microwave.

After forming and sealing, the bags are processed by a bag cutting machine to achieve the final size and shape. This popcorn bag converting machine efficiently separates each unit and prepares them for packaging. It supports roll-to-bag automation for high-output production, making it an essential part of any food packaging bag making machine setup.

6. Vision Inspection System

To maintain product quality, a machine vision system is used for real-time inspection. It checks the print quality, folding accuracy, susceptor placement, and overall structure. A reliable vision system for packaging quality control ensures consistent results and reduces waste. This system plays a critical role in popcorn bag inspection and AI-powered defect detection.

Whether you're producing standard paper bags or specialized laminated microwave popcorn bags, this complete equipment line provides an automated, high-efficiency solution. It supports the production of food-grade, heat-resistant popcorn bags that meet both safety and market standards.

Common materials required

Kraft Paper

PET film / BOPP

PE heat seal layer