Fully Automatic Kraft Microwave Popcorn Bag Forming Machine ZDF-300

- Two machines to finish the microwave bag

- Opitional:Bag Gluing Machine

Description

Machine features:

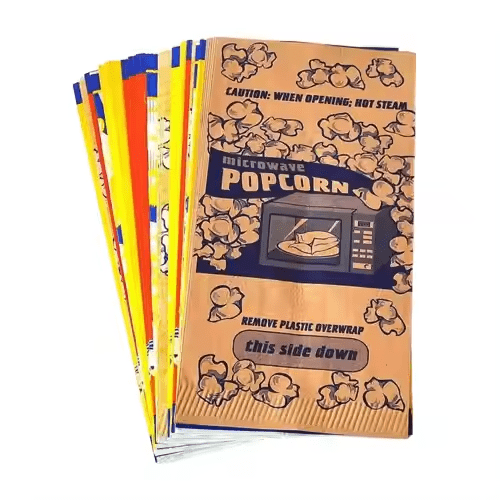

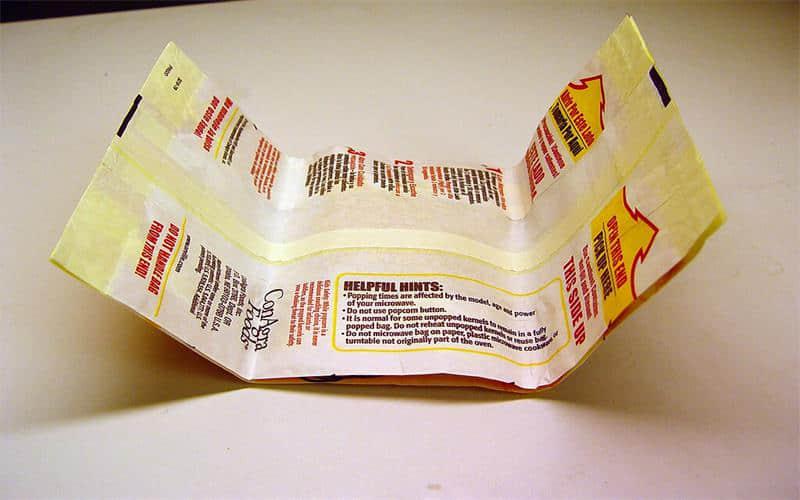

A novel microwave popcorn packaging bag structure comprises a food contact layer and a surface printing layer, adding an oil-proof composite layer between the food contact layer and the surface printing layer.

Described oil-proof composite layer is a kind of membrane structure that the active ingredient is PE or PET, is tightly pasted between food contact layer and surface printing layer, and material itself has oil-proof properties, and food contact layer no longer needs to be coated with oil-proof agent externally, and the problem that the Teflon component in the oil-proof agent during microwave heating is volatile and forms harmful substances at high temperature has been eliminated. The beneficial effects of the present invention are that:

3. Eliminate the damage caused by harmful chemicals to human health.

To make microwave popcorn bag,you need two machines as follows:

1、The machine is used to put the heating film on the paper bag of Microwave popcorn bag.

The machine is with computer to set the speed,length etc.with photocell,inverter speed control.

Model | TP-600 |

Bag width | 10-600mm |

Bag length | 30-500mm |

Machine working speed | 50-150pcs/min |

Precision | ±0.2mm |

Total power | 4.5kw |

Machine weight | ≈1300kg |

Machine size (LxWxH) | 3500×1250×1700mm |

2、The bag sealing and cutting machine to make the final bag.also can used sealing and cutting common bag.

Model | ZDF-300 |

Max Bag width | 300mm |

Bag Length | 30-500mm |

Working Speed | 60pcs/min |

Precision | ±0.2mm |

Total Power | 4.5kw |

Machine Weight | ≈1300kg |

Machine size(L×W×H) | 7000×1600×1500mm |

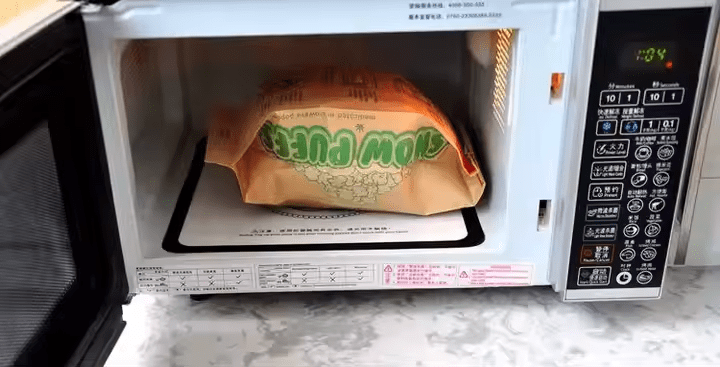

Bag Samples