Medical Sterilization Pouch Making Machine | High-Speed Medical Packaging Equipment

- Fully Automatic

- Can be Pouch or Rolling

Description

Boost your medical packaging efficiency with our Medical Sterilization Pouch Making Machine, designed for high precision sealing, stable performance, and maximum productivity. This machine is the preferred choice for hospitals, pharmaceutical suppliers, and medical device manufacturers who require reliable sterilization pouch production at scale.

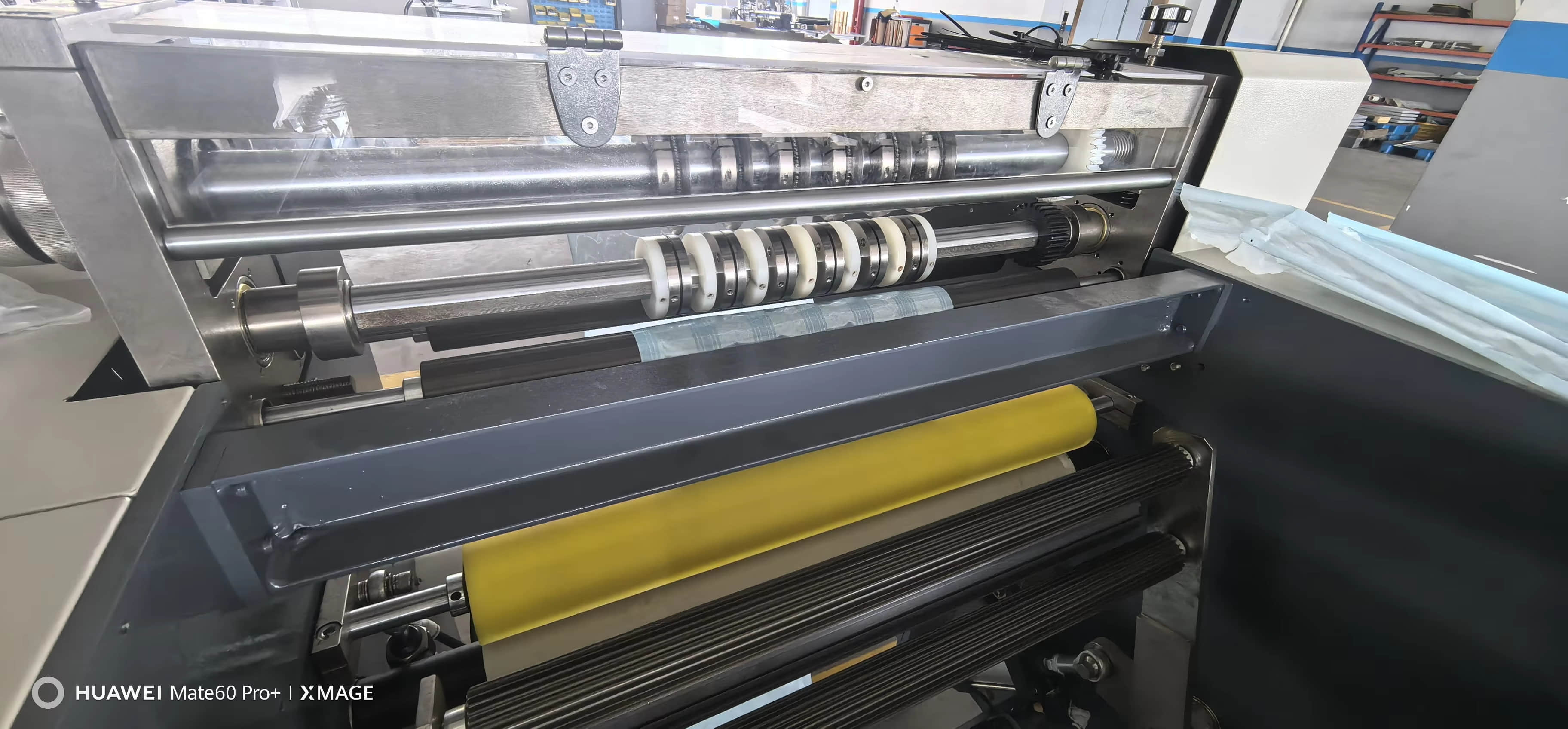

Key Features of the Sterilization Pouch Making Machine

Heavy-Duty Structure: Built with reinforced steel frame for long-term durability and low maintenance.

High-Speed & Low-Noise Operation: Produces up to 150 pouches per minute with smooth motion — optimized for cleanroom environments.

Advanced Servo Control System: Equipped with industrial PLC, imported servo motors, and HMI touchscreen for accurate speed control and real-time adjustment.

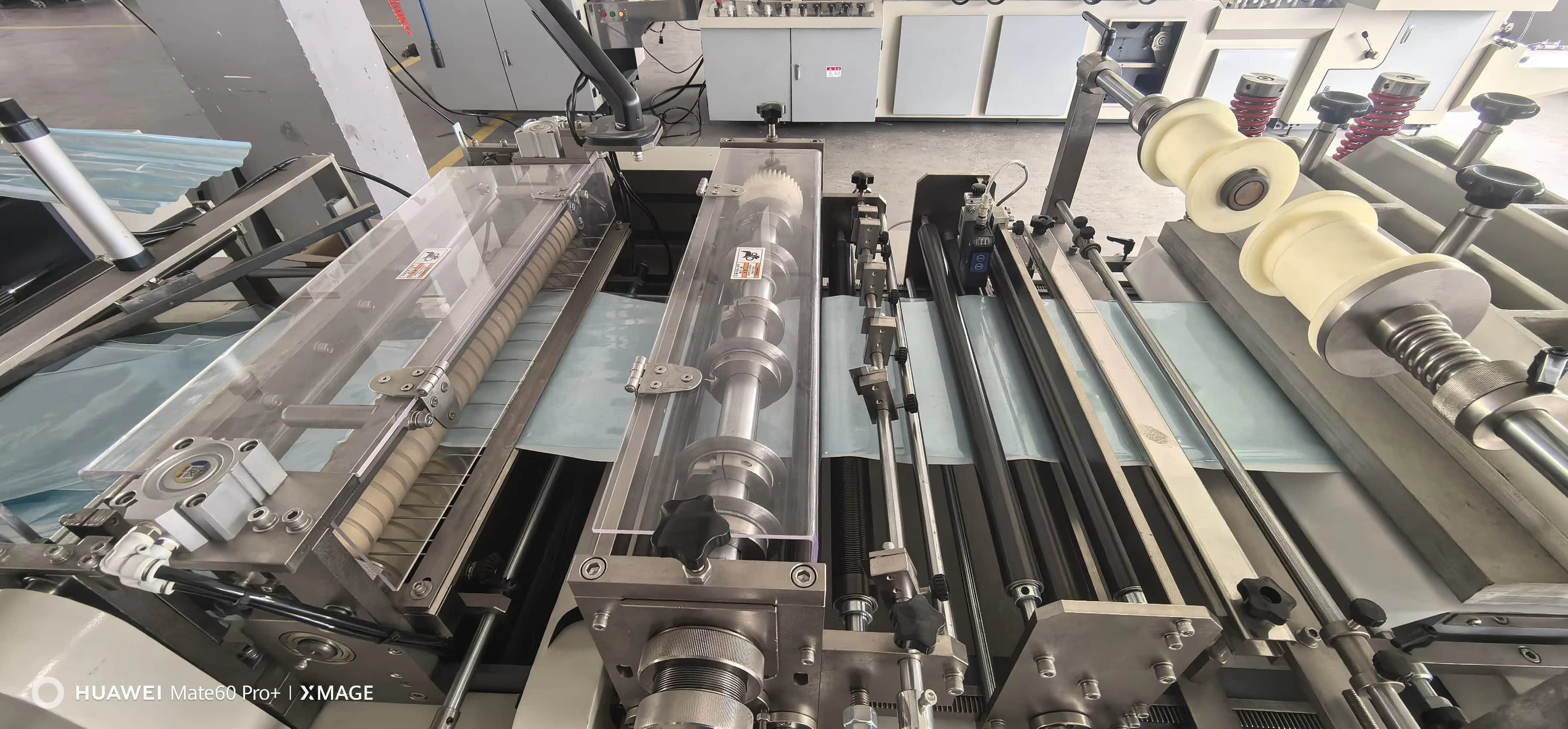

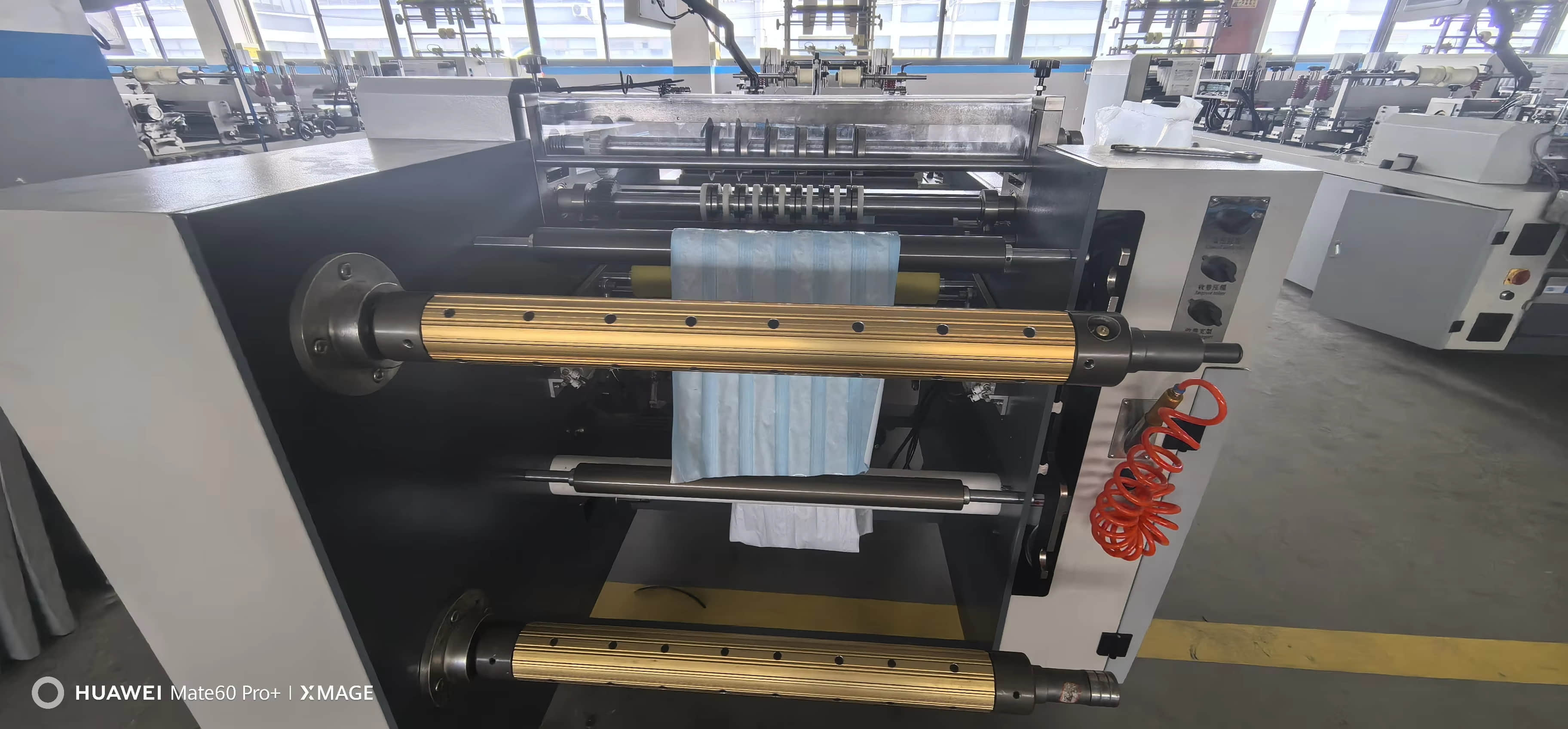

Precision Heat Sealing Technology: Multi-zone digital temperature control up to 300°C, ensuring strong, wrinkle-free, airtight seals for sterilization pouches.

Double Unwinding System: Pneumatic locking with EPC web guiding for consistent film feeding, reduced waste, and flawless alignment.

Intelligent Tension Control: Dynamic compensation rollers guarantee stable material tension during production.

Versatile Output Options: Supports both reel-to-reel production and individual pouch making, powered by high-resolution photocell tracking.

Inline Punching & Cutting: Integrated air-pressure punching (16mm), disk knives, and precision cutters for longitudinal and transverse trimming.

Centralized Touchscreen Operation: Easy adjustments for pouch size, sealing parameters, and cutting modes.

Technical Specifications

Bag Size: 100–600mm width | up to 600mm length (single/double pouch)

Speed: Max. 150 pcs/min or 25m/min

Power: ~22KW | Weight: ~3100KG

Dimensions: 6500 × 1530 × 1910 mm

Max. Coil Diameter: φ600mm

Sealing Temperature: 0–300°C (6 independent heating zones)

Applications of Sterilization Pouch Making Machine

Our machine is widely used for producing flat sterilization pouches and self-sealing pouches, suitable for:

Hospitals & Medical Centers

Surgical Tool Packaging

Dental Clinics & Labs

Pharmaceutical Industry

Medical Device Manufacturers

Why Choose Our Medical Sterilization Pouch Making Machine?

Equipped with world-class components (Panasonic servo, Datalogic sensors, Airtac pneumatics).

Stable, efficient, and consistent production even in high-demand environments.

User-friendly design reduces operator training time and improves overall workflow.

Trusted by global medical packaging suppliers for reliability and compliance with industry standards.

👉 Upgrade your medical packaging line today with the best Medical Sterilization Pouch Making Machine from China's leading manufacturer.

More machine pictures

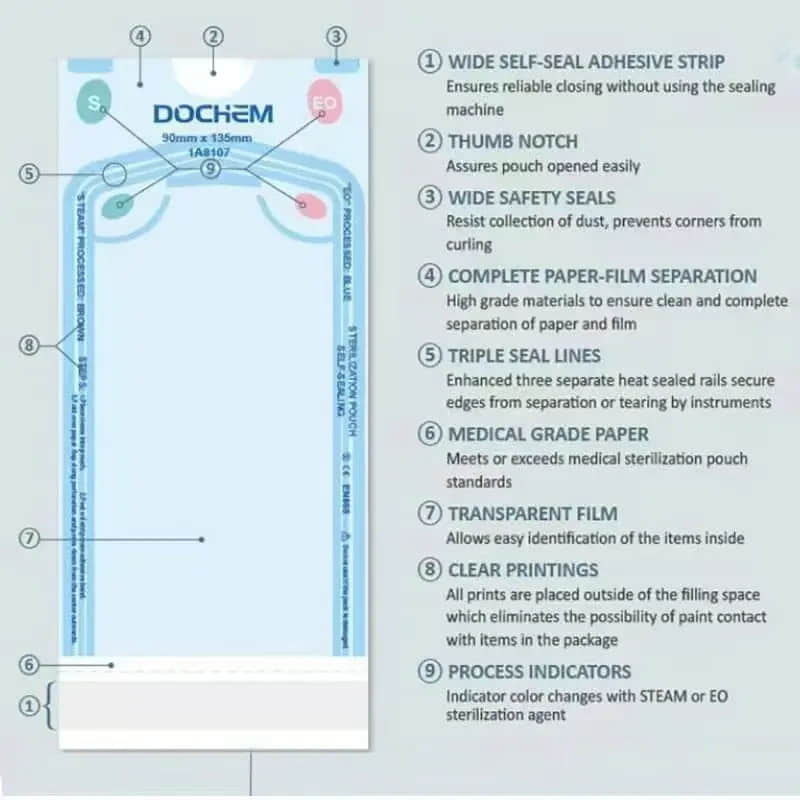

Bag Samples