Medical Sterilization Pouch Bag Making Machine For Plastic Film and Paper Medical Use Reel EO Steam

- Fully Automatic

- Can be Pouch or Rolling

Description

Medical Sterilization Pouch Making Machine features

1.Excellent processing and assembling, with elegant shape, reasonable structure.

2.High steady operation speed,low noise.

3. Introduce industrial PLC computer servo control and operate system, imported man-machine interface control, to provide a curate protection for the speed operation.

4. Imported servo control, main motor with inverter speed control.

5. Hot pressure digital control, to make products more smooth, improve the rate of finished products.

6.The latest new type pneumatic locking double-unwinding device, automatic tension and EPC control.

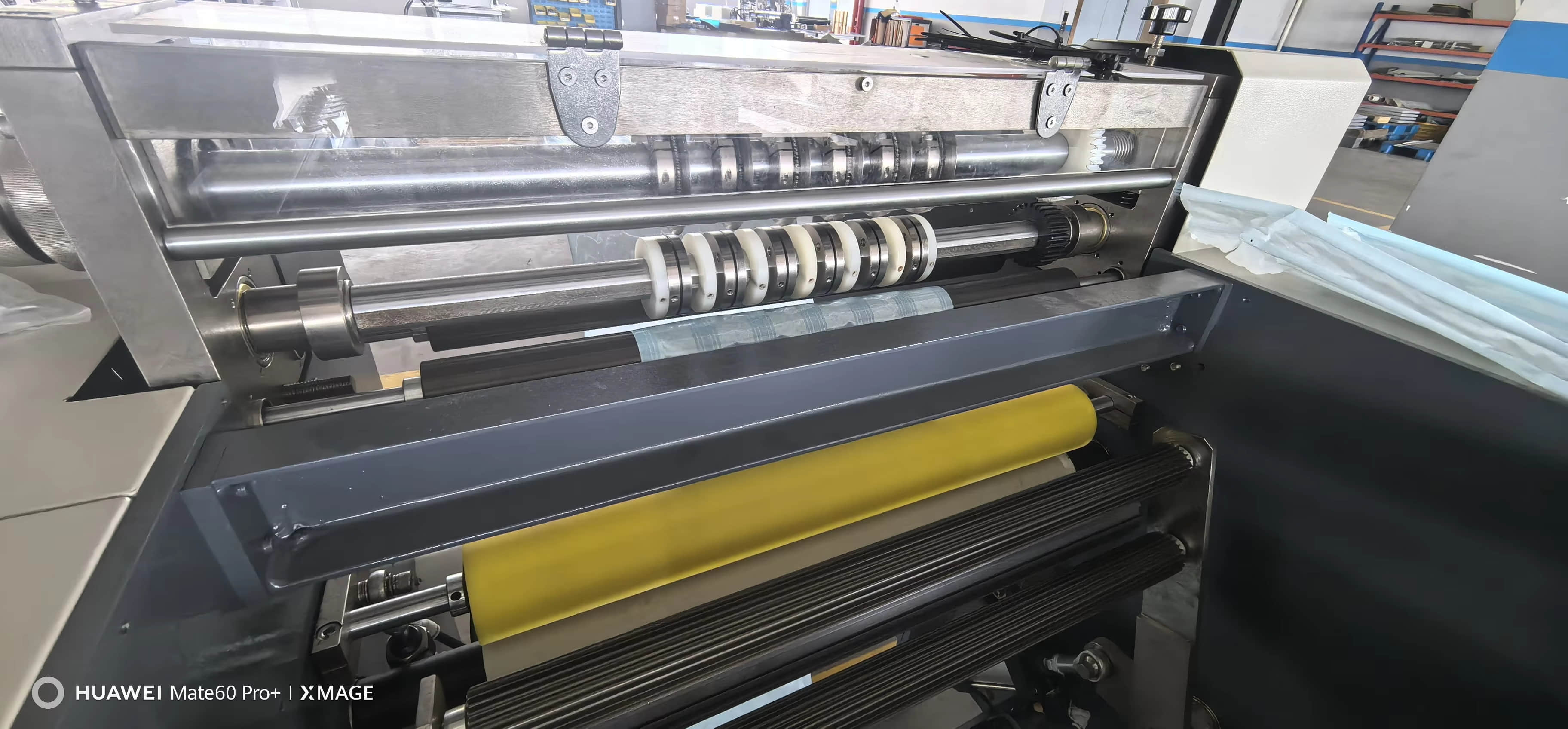

7.Constant tensioncontrol for double-unwinding, ensure the stability of material feeding.

8.Introduce dynamic compensation dancing roller for middle tension holding, to minimize the middle stage tension variation when the material passing by the machine. Stable middle tension control.

9.Introduce imported servo motor for out-feeding, final production section with dual functions, reel making and pouch making can be shifted very easily.

10.Introduce imported photocell length-fixation control system and auto punching device for pouch making.

11.Dual slip cam shafts,rewinding motor equipped with inverter and constant tension control device to ensure each rewinding rolls in the same tension, with neat end face.

Technical parameters

Main Electric Component:

Servo Motor for material feeding AC

main motor with Inovence inverter for main machine

6 routes temperature control

constant auto tension control for unwinding section

Max. Mechanical speed:150pcs/min,Max 25Meter/min

Making Bag size:

Length: 600 mm and Double self-sealing bag

Horizontal bag making total bag length 50-600 mm

Single bag length not exceeding 300 mm

Bag making width: 100~600mm

Maximum size of coil: φ600mm

Heat sealing knife: 1 group

Lines of Pouch Production: 1-5Lines

Cooling: 1 group

Electric Heating Temperature Control:6 routes

Temperature setting range:0~300℃ (could be set as needed)

Total Power Capacity:About 22KW

Overall Dimension:6500× 1530×1910 (L×W×H)

Net weight:about 3100KG

Machine configuration:

1、Unwinding unit:

(1)Structure: Horizontal, Controlled by dancing roller, cylinder,magnetic powder brake, frequency converter motor,infeed roller sensor and control system.

(2)Loading Shaft for unwinding: Air shaft with pneumatic lock device, diameter:3 inch (76mm) with ruler.

The gear ofthe discharge shaft has a protective cover.

2、Unwind tension:

Control mode: Controlled by computer, magnetic powder brake, compensation potentiometer, pneumatic cylinder dancing bar, composite type constant tension control system.

3、Web Position Control Device

(1)Control Method: dual photocells.

(2)Detective Method: Reflection type photocell Two color control,blue and green ( point at white paper,green white and blue transparent plastic),Tracking have auto,manual,monocular,binoculus,close.

4、Film inserting unit Equipped with Membrane folding devices, easy to adjust width and place of film, Easy to adjust and stereotype, can produce Stereoscopcs packing bag.

5、Teeth Shape Disk Knife: 2 Group.

6、Punching device Punched by air-pressure, equipped with one set Circular punchingdevice, diameter 16 mm.

7、Heat Sealing Unit

(1)Scalding plate form with upper heating.

(2)Sealing Unit temperature control difference ±3℃, all heating plate temperature difference less than 3℃.

(3)Sealing pressure use aerodynamic equilibrium pressure, adjustable ofsize, Display deviation ±0.1kg.

(4)Heating plate is adjustable, range in 5mm.

(5)Sealing time is adjustable.

(6)620*620mm whole set heat pressure, 6 routes heating, 1 group.

(7)Digital pneumatic pressure detective device: 4 groups(AIRTAC of Taiwan)

8、Cooling Device

400*620mm 1 group (water chilling unit shall be prepared by customer).

9、Main transmission device

(1)Structure:Crank rocker push-pull type.

(2)Diving mode:3.7kw inverter for 3.7kw 3P asynchronous motor.

(3)Driven mode: Speed reducer with ratio :1:13.

(4)Control mode: Centralized by PLC.

(5)Motion mode: Vertical up/down of frame work.

(6)Discharging traction near cutter: adopt 1.5KW Panasonic servo motor.

(7)The ironing discharging traction is controlled by servo motor, and the length is adjustable.

10、Automatic positioning device

Optoelectronic eye: Italy Datalogic.

(1)Location correction method:Computer control of photoelectric and servomoter encoder feedback.

(2)Step length and Actual length are agreement,the errorof indefinite length tracking is less than ±2mm,Alarm prompt for equipment after spectified cutting times.

(3)Cursor tracking can set many times, alarmed and stopped when miss the cursor.

11、Longitudinal cutting

Structure :Longitudinal cutting of circular knife Equipped with 6 groups of disk knife and Waste blowing device.

12、Transverse Cutter

(1)Structure :upper Cutting knife + adjustable device +fixed lower knife.

(2)Shape : vertical double slideway Pneumatic Top pull shear.

(3)Transmission : Use Eccentricity axis power.

(4)Adjustment : Horizontal movement Pull handle adjustment.

13、Glue place device

Structure :Double station blowing ,each station can fine-tuning.

14、Electrostatic elimination

Discharge traction place have Electrostatic elimination and safety protection.

15、Collecting table

Stainless steel collecting table.

16. Winding device

The machine is equipped with a winding device, which can be used for tube bag production.

(1)Structure: horizontal double position (composed of magnetic powder clutch, air cylinder, swing roller, traction roller sensor and control system),up and down double axis receiving.

(2)Receiving shaft: mechanical slip camshaft. The inner diameter of applicable paper pipe core is 3 inches (76mm) standard pipe diameter.

(3)Receiving tension: a composite constant speed tension system composed of tension controller, magnetic powder clutch, compensation potentiometer and cylinder counter swing roll.

(4)Winding drive: frequency conversion motor and chain drive, winding speed adjustable.

17、Control system Setting function

(1)A panel control of the whole equipment, have a switch in unwind part.

(2)Speed 0-150 pc/min, can adjust it.

(3)Sealing time can adjust.

(4)Length of product can adjust.

(5)Automatic search color code.

(6)Automatic lifting function of hot plate after shutdown.

18、Mechanical requirements

(1)Standard parts in whole machine.

(2)Shield in whole machine, shape is beautiful and easy to operation.

(3)In line with national standards of all parts.

(4)The overall appearance of the equipment is beautiful and generous, the body structure is simple and smooth.

(5)The strength of connecting screw meets the requirements of this machine.

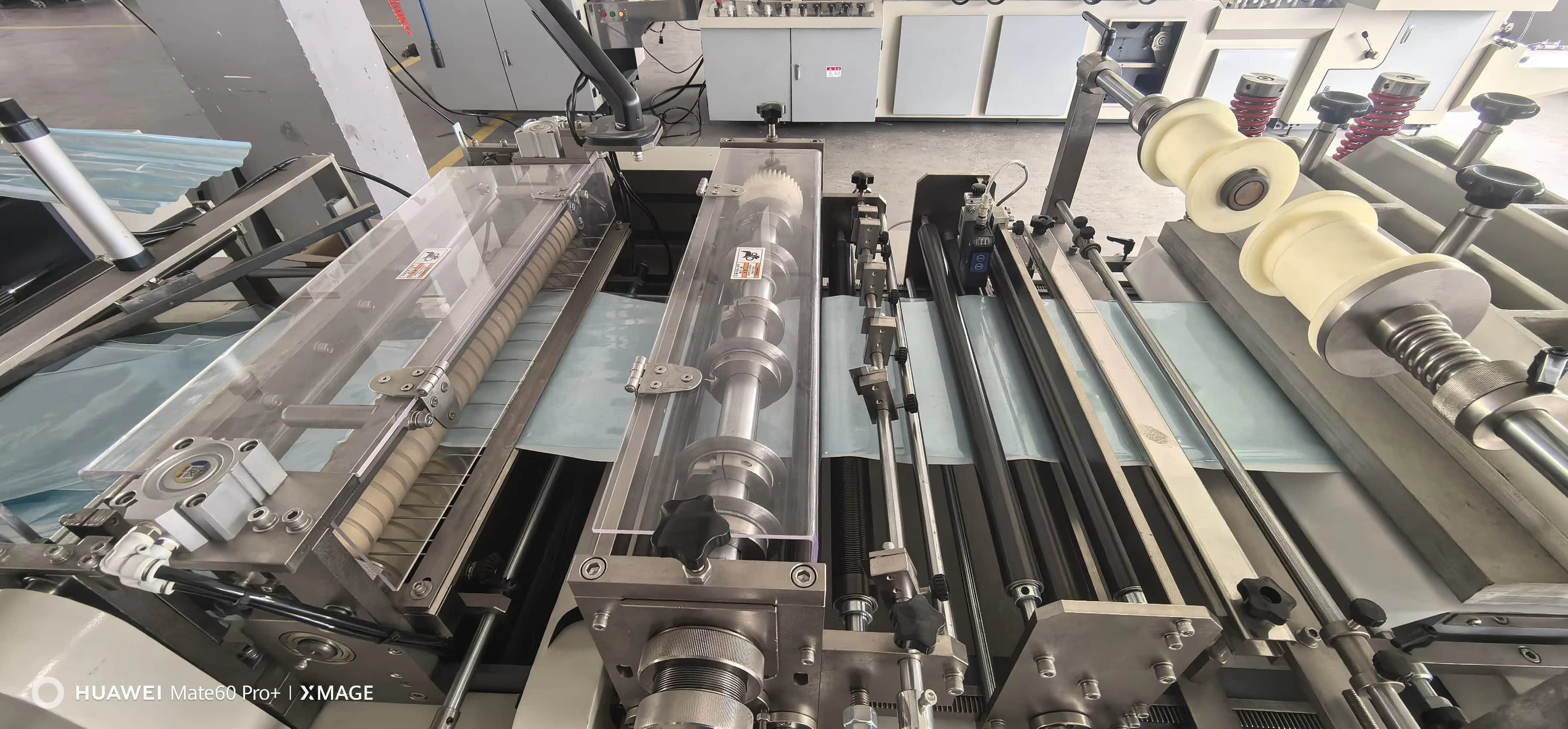

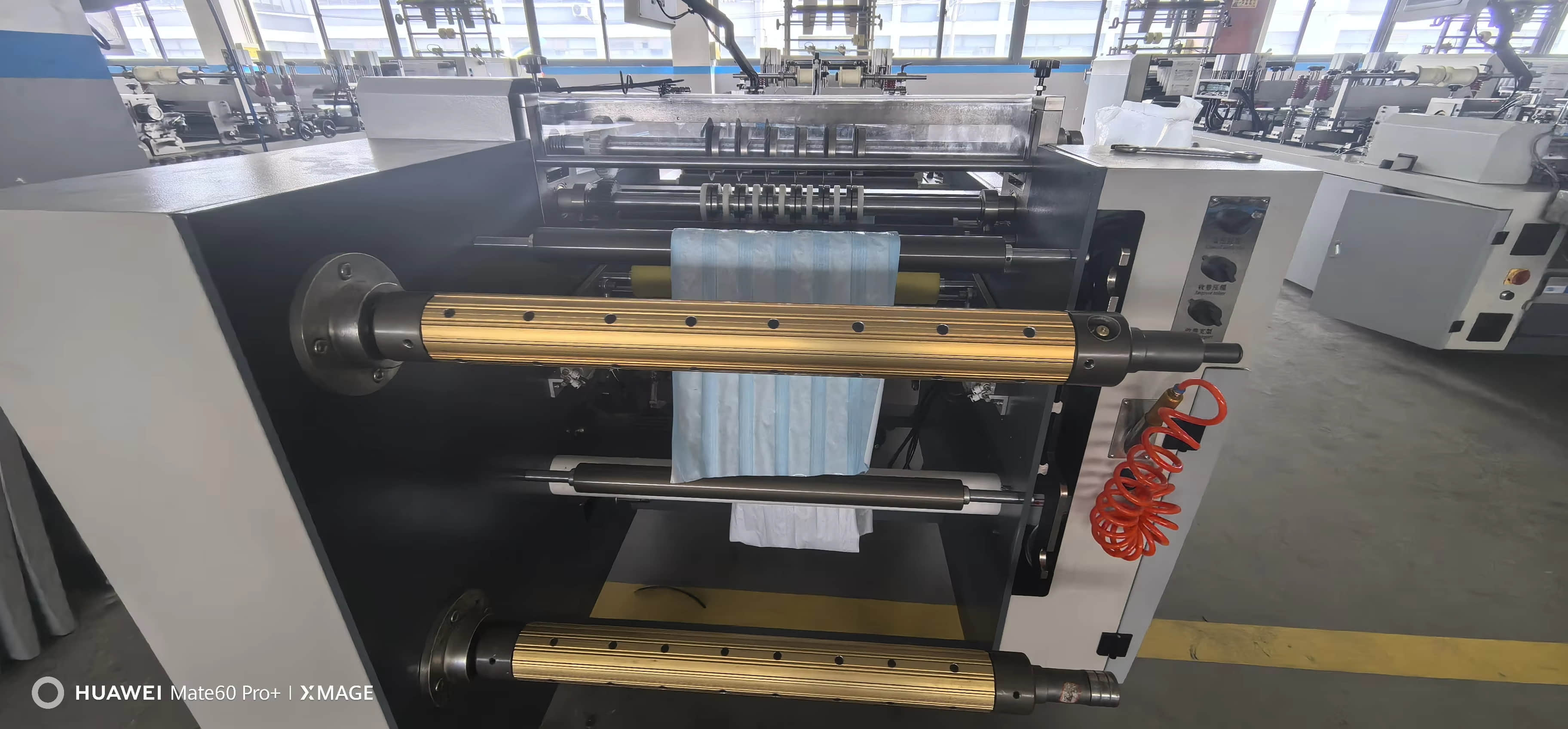

More machine pictures

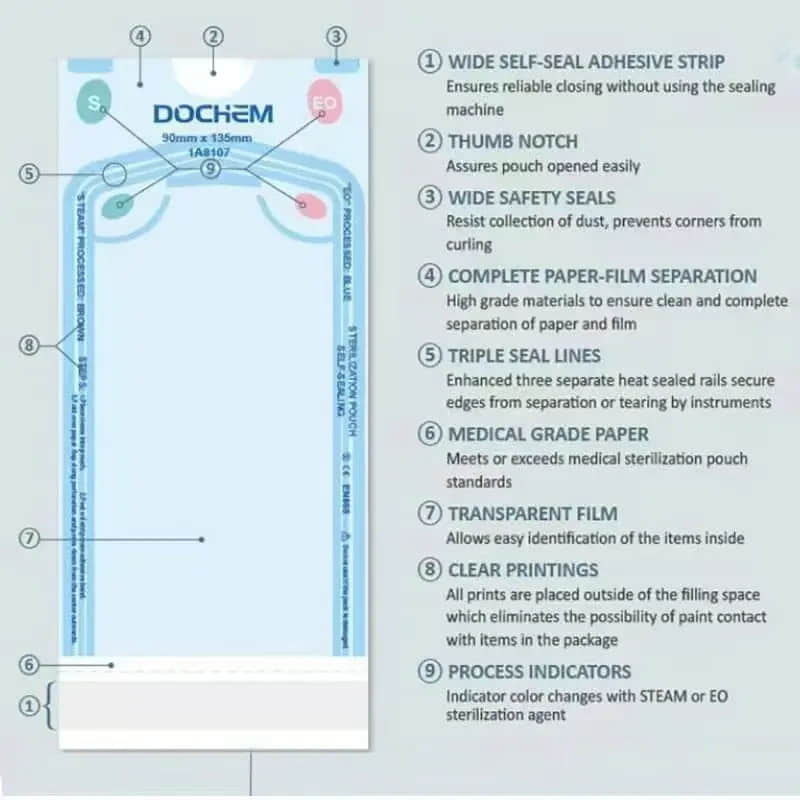

Bag Samples