ZF-800Plus Automatic Food Lunch Carton Erecting Forming Machine

Description

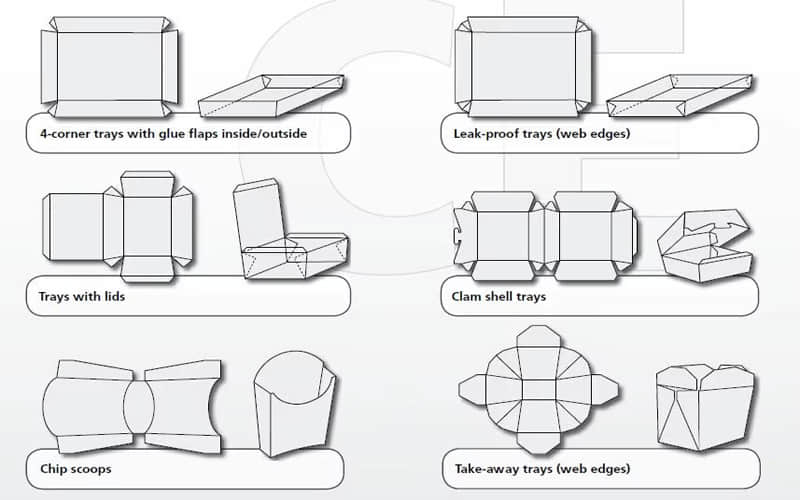

The automatic food lunch Carton Erecting Forming Machine is an ideal choice to produce hamburger boxes,chips boxes,takeout container,etc.It adopts micro-computer,PLC,alternating current frequency converter ,the vacuum-sucking paper feeding,auto gluing,automatic paper tape counting,chain drive.All of these main parts and electric control system adopts imported brand to guarantee steady working,precise positioning,smooth running,safety and reliability operation.

Automatic Food Lunch Carton Erecting Forming Machine Advantages:

1.Feature of stereo box die-cutter: High efficiency, Reaches 180-300pcs/min.

2.Multifunctionality: Can manufacture the products such as meal box, chips box, stereo box or burger box with different specifications on one machine only by changing its molds.

3.Carton erecting forming machine applies water-based adhesive coating device, attains high efficiency and very high precision. Water-based adhesive, as water soluble adhesive compostion, is a kind of food-grade glue.

4.Most of the machine applies high-quality sealing bearing, prevents from dust or liquid penetrating and impacting the service life of bearings, with long service life and good stability.

5. Carton erecting forming machine adopts 5 motors and 4 servo motors for control, which is faster, more stable, and more accurate.

6.Main mould employs pine wood, enjoys high efficiency when replacing its mould.

7.Can automatically collect, store and count finished products, and install additionally counter as per the requirements of customers.

8.The machine applies PLC intelligent control system, and automatically stop when there is paper jamming or no paper. It can avoid unnecessary harm caused by the contact between worker and operation mechanism during the production process.

9.More Easy and fast mould change system than other suppliers. (contact us to show you details)

Standard configuration:

* Integral electric control box ·Feeding unit

* Compressed air device ·Moulding unit

* Water based adhesive coating device ·Servo control unit

* Discharge unit ·A forming die

Opitional :

Hot melt coating system

Air compressor / Dryer

Plasma Corona

380V power :8KW

Machine power: 380v

Technical Specification

Type | ZF-800PLUS |

Production capacity | 50-300pcs/min |

Suitable Material: | 200-600g/m2 card paper,corrugating(max):1.5mm |

length: | L100-650mm,degree:5°-40° |

width: | B100-500mm hight H15-200mm |

Suitable Material: | 200-600g/m2 card paper,corrugating(max):1.5mm |

Total Power: | 8kw |

Total Weight: | 2.2T |

Overall Dimension: | 3600 x 1600 x 1600 mm |

power source | 380V 50HZ |

What Make Us Different?

NICE FEEDING BY OUR SERVO MOTOR

WATER BASED GLUE

HOT MELT GLUE USED AS YOU WANT

HIGH QUALITY NYLON MOULD TO MAKE NICE BOX

HIGH OUTPUT AS YOU WANT