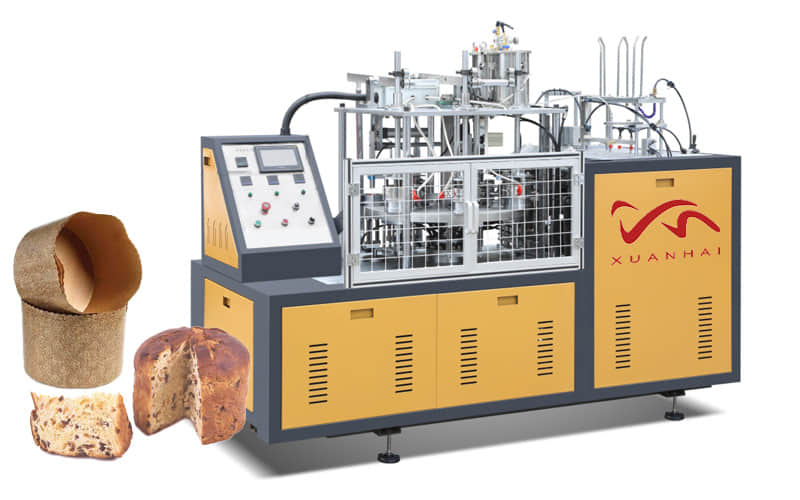

Automatic Round Panettone Paper Cake Cup Machine Muffin Baking Mold Machine

Description

The machine is the automatic environmental machine with multi-running positions, change the situation of making Panettone Tray Cup

by hand histroy. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, bottom-punching, rolling, guling. It

is an idea equipment of producing backing cups for Panettone tray cup.

Easy exchanging molds to make different sizes paper cake cup.

Work flow:

Blank Raw material paper → printing (printing machine) → punching (punching machine) → finished paper muffin cup (paper cake tray forming machine) → packing (depends)

MAIN PARAMETER:

Model | GT-PF | GT-PF-E | GT-PF-Y |

Size of paper diameter | Base :Φ50-φ100mm Height : Φ50-φ170mm | Base :Φ110-φ160mm Height : Φ50-φ170mm | Base :Φ150-φ200mm Height : Φ50-φ170mm |

Material | Kraft paper 50-150gsm | ||

Thickness of paper | 50-150gsm | ||

Speed | 20-35PCS/MIN | 20-25PCS/MIN | 10-20 PCS/MIN |

Power supply | 380V,50HZ,220v ( it can be changed if customer require) | ||

Total Power | 4.0 KW | 4.0KW | 5.0KW |

Machine weight | 2000kgs | 2500KG | 3000KG |

Measure(L*W*H) | 2300*1800*1800 mm | 2600*1800*1800 mm | 2800*2000*2000mm |

Air supply | 0.5Mpa 0.3 m3/min (need buy a separate air compressor) | ||

HS CODE | 84413090000 | ||

Finished samples: