ZF-800 Zhongfa Manufacturer Fully Automatic Carton Erecting Machine For Hamburger Box

Description

Carton Erecting Machine for Fast Food Packaging | Automatic Hamburger Box Making Machine

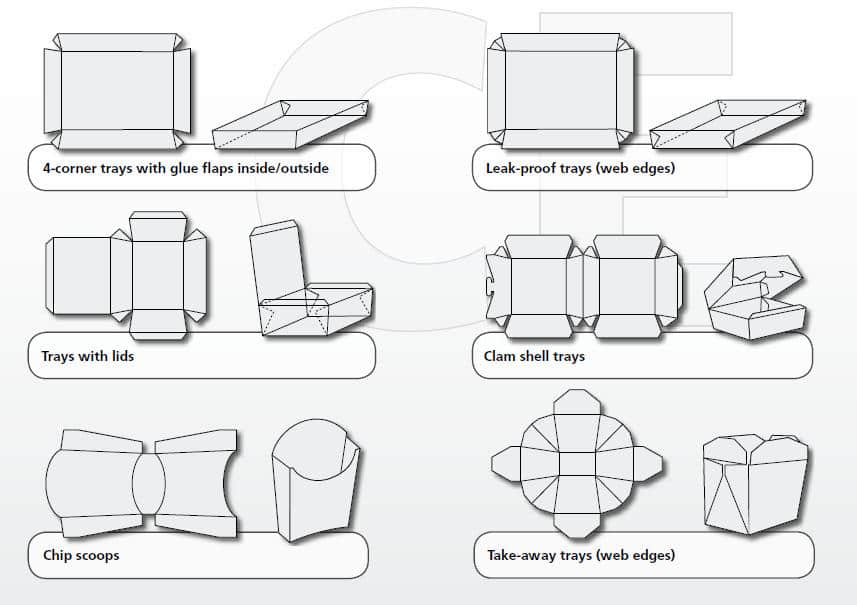

The carton erecting machine is the ultimate solution for producing hamburger boxes, chips boxes, takeout containers, and other food cartons with speed and precision. Designed for modern food service packaging, this automatic hamburger box making machine efficiently converts cardboard paper into durable cartons, ensuring strong and reliable packaging for fast food products.

Why Choose Our Carton Erecting Machine?

Versatile Applications: Perfect for making burger boxes, French fries boxes, snack cartons, and various disposable food containers.

High Efficiency: Automates the folding and gluing process, reducing manual labor and cutting production costs.

Consistent Quality: Ensures standardized, hygienic, and professional packaging to enhance food presentation and customer satisfaction.

Strong & Durable Cartons: Forms rigid boxes that withstand handling and transportation, keeping food intact and fresh.

Ideal for Food Industry: Widely used in fast food chains, restaurants, catering services, and takeout businesses.

Boost Productivity with a Hamburger Box Making Machine

Using a hamburger box making machine not only speeds up the packaging process but also improves operational efficiency for fast-food operators and caterers. By adopting this carton erecting technology, businesses can:

Increase daily output with minimal manpower

Maintain packaging uniformity for a professional brand image

Reduce packaging costs while ensuring food safety

👉 Upgrade your production line with our carton erecting machine — the reliable choice for high-speed food carton manufacturing.

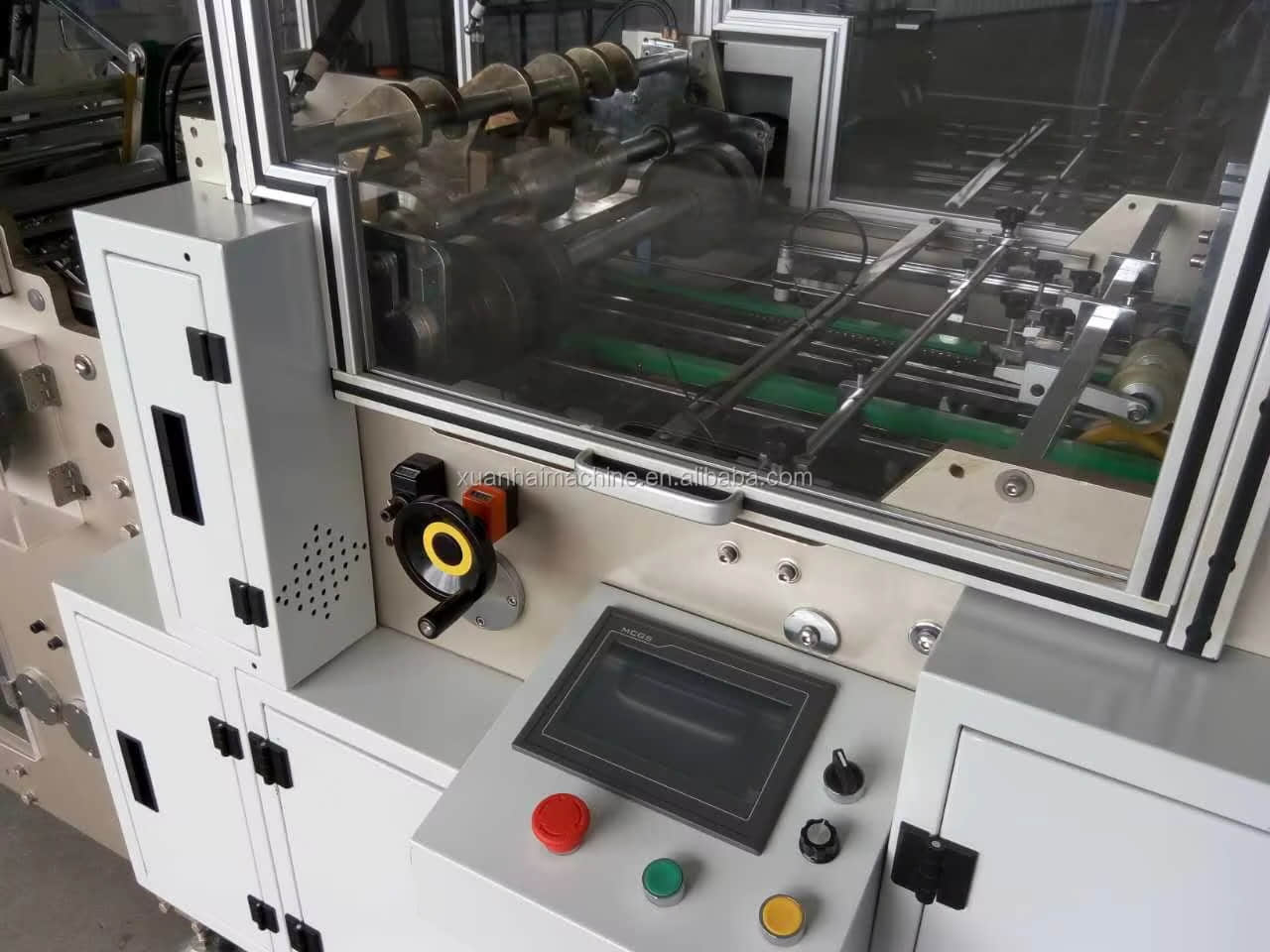

Automatic hamburger box making machine main components

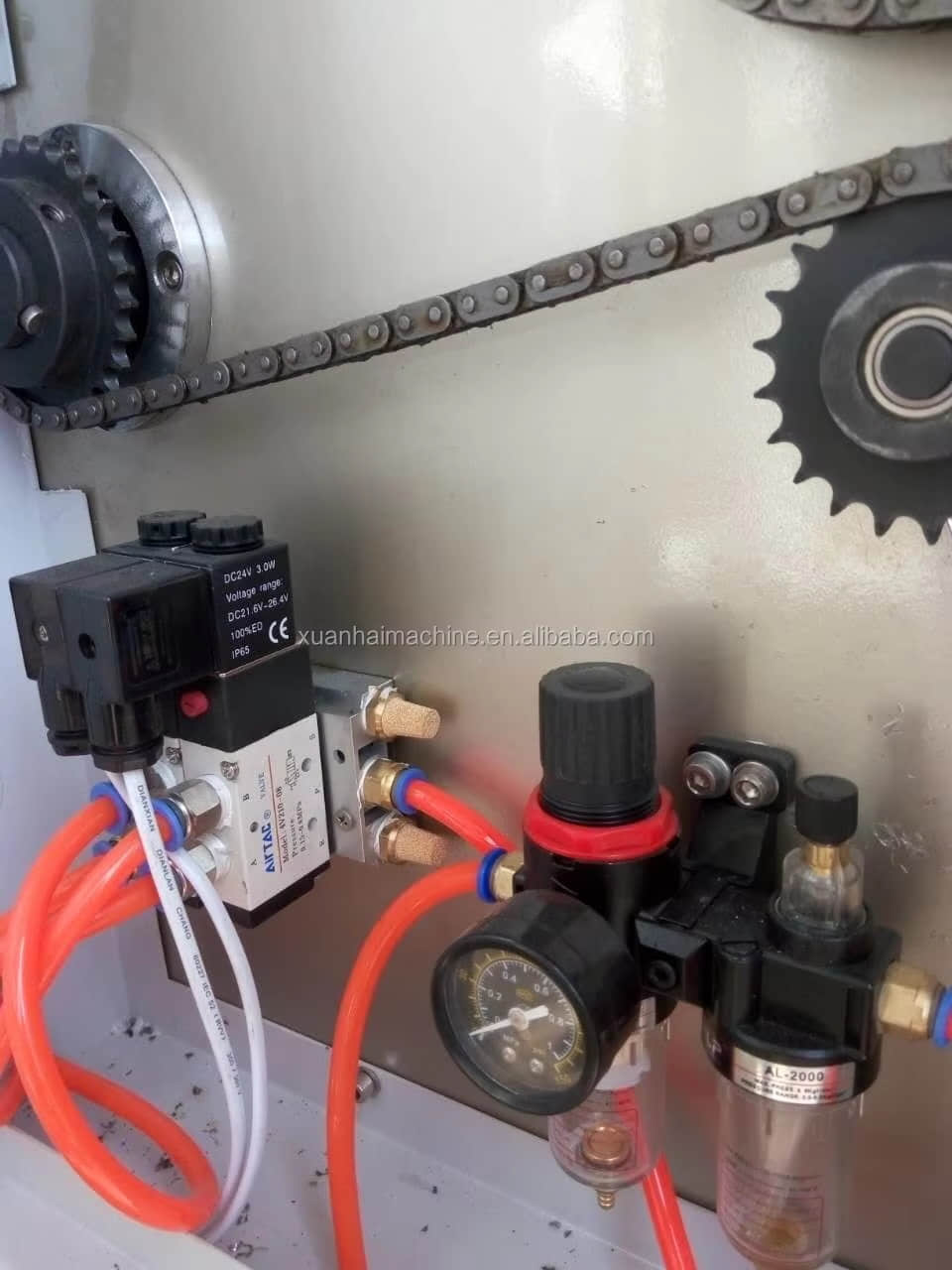

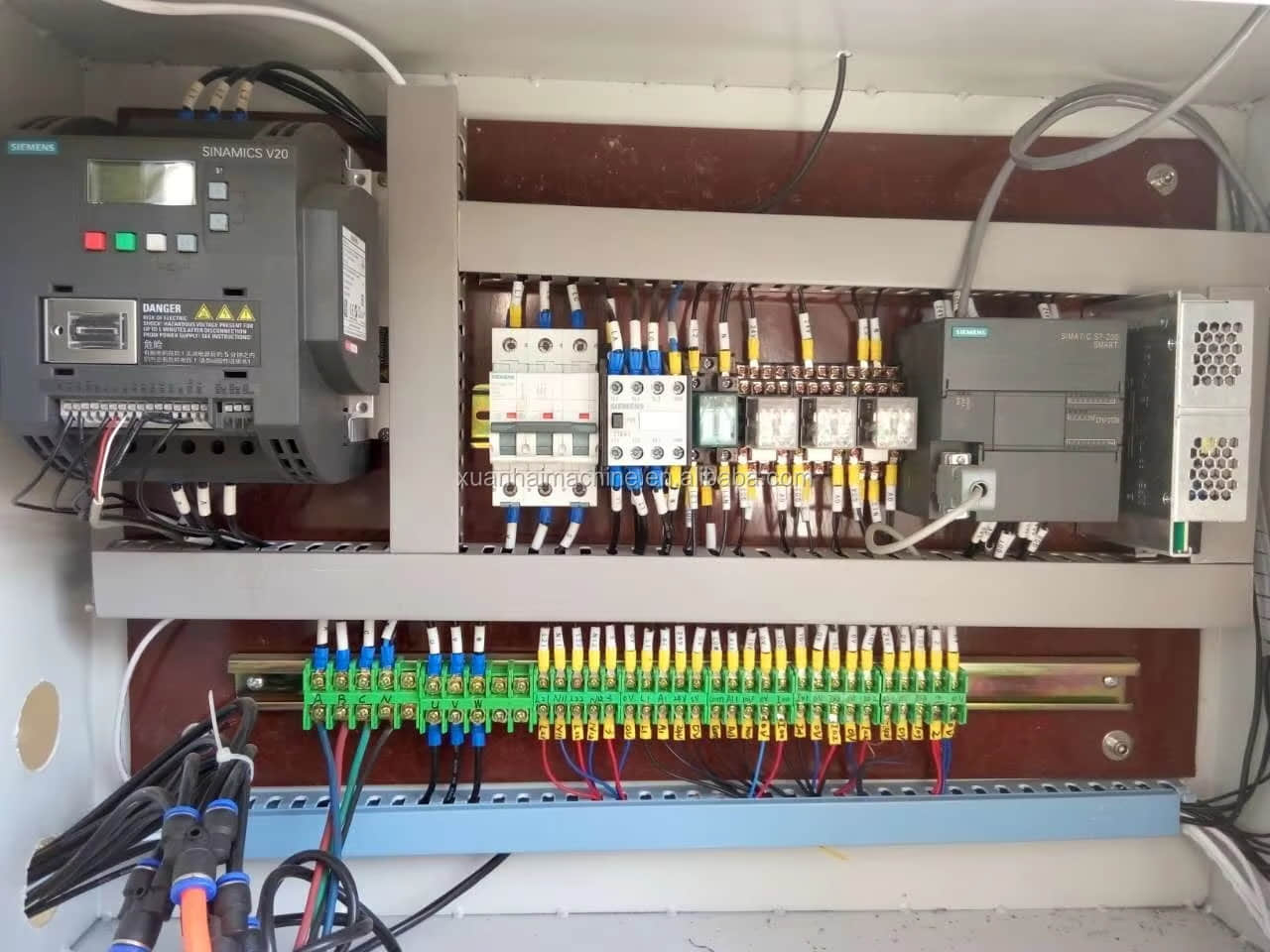

It adopts micro-computer,PLC,alternating current frequency converter ,the vacuum-sucking paper feeding,auto gluing,automatic paper tape counting,chain drive.All of these main parts and electric control system adopts imported brand to guarantee steady working,precise positioning,smooth running,safety and reliability operation.

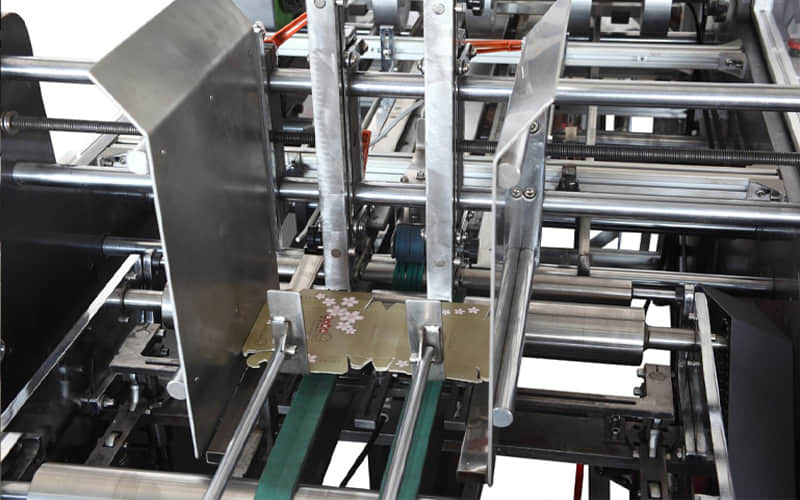

Paper feeding unit feeds paper, pre-cut to the desired shape and size, into the machine.

Gluing unit applies glue to the corners and creases of the box.

Forming unit heat-presses the paper through a die to form the box shape.

Stacking unit collects and stacks the finished boxes for easy transport and storage.

Features of automatic hamburger box making machine

1.High efficiency, reaching up to 180 pcs/min.

2.This machine utilizes a water-based adhesive coating device for high efficiency and precision. Water-based adhesive is a food-grade adhesive, as it is a water-soluble adhesive.

3.By simply changing the mold, a single machine can produce different types of lunch boxes, such as potato chip boxes, clamshell boxes, or hamburger boxes.

Automatic hamburger box making machine can adjust the speed and size of the boxes based on customer needs and preferences.

4.The main mold is made of pine wood and is specially designed for easy mold changes, saving time and increasing efficiency.

5.It can automatically collect, store, and count finished products, and can be equipped with a counter upon customer request.

6.Automatic hamburger box making machine utilizes a PLC intelligent control system, automatically shutting down in the event of a paper jam or lack of paper, preventing unnecessary injuries to workers during production due to contact with the operating mechanism.

Technical Specification

Model:ZF 800 Automatic Hamburger Box Making Machine

Production speed: Max 160pcs/min

Roofless box MAX:160pcs/min

Square box MAX:150pcs/min

Hot Dog&Burger Box MAX:120pcs/min

Food box MAS:100pcs/min

PS: The above-mentioned production speed is the value under common conditions,the actual value is varied according to the pattern of box, the materials,quality and specifications.

Materials:(200-600gsm) single PE coated paper or 1.5mm thickness corrugated paper.

Detailed specifications

Sample box