Automatic Disposable Ice Cream Cone Paper Wrapper and Firework Cone Wrapper Making Machine

Description

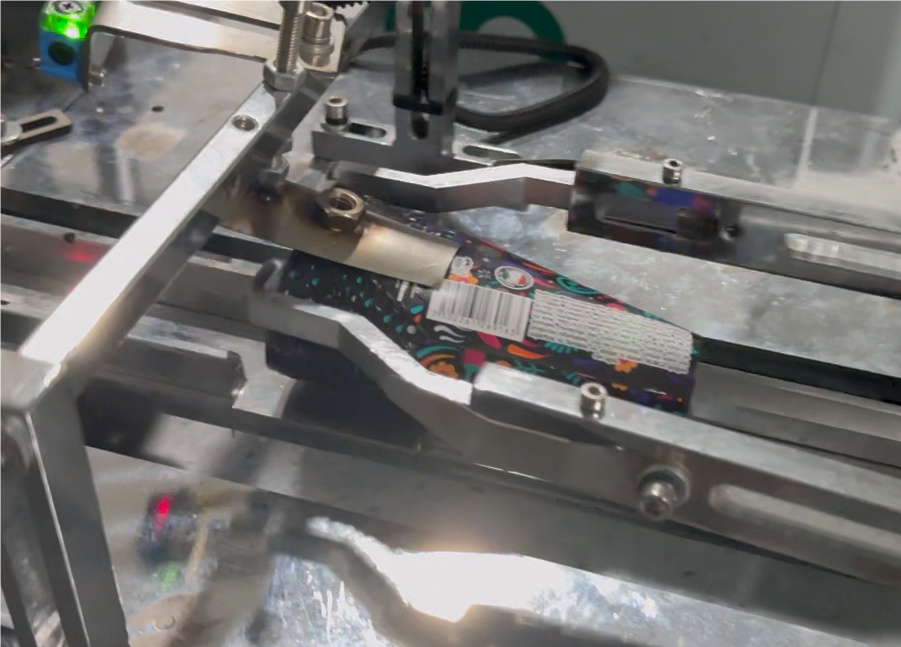

The Automatic Disposable Ice Cream Cone Paper Wrapper and Firework Wrapper Making Machine is designed for high-speed, precision production of cone-shaped paper wrappers. Ideal for both food and decorative applications, it can produce ice cream cone wrappers and cone-shaped fireworks covers using single-sided or double-sided PE coated paper, UV varnished cardboard, and other high-quality paper materials.

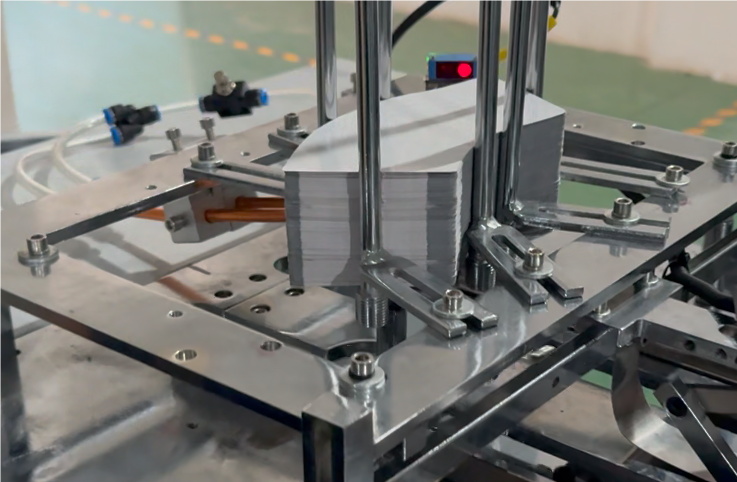

The machine automatically feeds pre-cut paper into the cone forming section, precisely splices shapes using a robotic system, and seals both sides together. The ultrasonic heating device eliminates the need for glue, ensuring a cleaner, stronger, and eco-friendly seal. Finished cones are neatly stacked and collected for packaging.

Key Advantages

High-Speed Production – Output of 80-100 pcs/min, ensuring maximum efficiency for mass production.

Intelligent Sensor Failure Detection – The machine automatically stops when an error occurs, improving operational safety and reducing downtime.

Advanced Ultrasonic Heating – Seals paper thickness from 140-320gsm quickly and securely, reducing paper leakage, improving durability, and extending machine life.

Technical Specifications

Model: S12 Paper Horn Cone Machine

Paper Size: 50–150 mm

Raw Material: Single/Double-sided PE Coated Paper, UV Varnished Cardboard, etc.

Suitable Paper Weight: 140–350 gsm

Speed: 80–100 pcs/min

Total Power: 4 kW

Power Supply: 50/60 Hz, 380V/220V

Total Weight: 800 kg

Machine Size (L×W×H): 1900 × 1000 × 1550 mm

Side Welding Mode: Ultrasonic Heater (No Glue)

Air Source Requirement: 0.4 MPa, Output 0.6 m³/min

Applications

Food Packaging: Ice cream cone paper wrappers, snack cone sleeves.

Fireworks Packaging: Decorative cone covers for fireworks.

Custom Printing: Supports branded designs, colorful patterns, and food-safe coatings.

This automatic cone wrapper making machine is the ideal choice for businesses seeking high-speed, eco-friendly, and precision cone paper packaging solutions.

Machine Details