High-Efficiency ABA Three Layer Film Blowing Machine: The Best Solution for Express Bag Production

Description

Meet the Rising Demand for Courier Packaging with Advanced Film Blowing Technology

With the rapid growth of the e-commerce and logistics sectors, the global demand for express bags is soaring. This trend brings higher expectations for express bag making equipment, especially in terms of efficiency, material savings, and film quality. The ABA film blowing machine emerges as the ideal solution—offering a perfect combination of structural innovation, high productivity, and cost-effectiveness.

🧩 Three-Layer Co-Extrusion Design for Optimal Performance

The ABA film blowing machine features an advanced three-layer co-extrusion structure composed of two extruders and a co-extrusion die head. The A-B-A layout enables optimal use of materials:

Layer A (surface and bottom): Uses premium materials like HDPE to ensure excellent surface finish—smooth, glossy, and durable.

Layer B (core layer): Incorporates cost-effective fillers like calcium carbonate, significantly lowering raw material expenses without compromising strength.

This intelligent structure enhances film toughness, tear resistance, and overall load-bearing capacity—ensuring that express bags can protect parcels throughout transport, reducing the risk of product damage.

✅ Ideal for manufacturing high-strength poly mailers, courier bags, and shipping pouches.

⚙️ High-Speed Output with Industrial-Grade Components

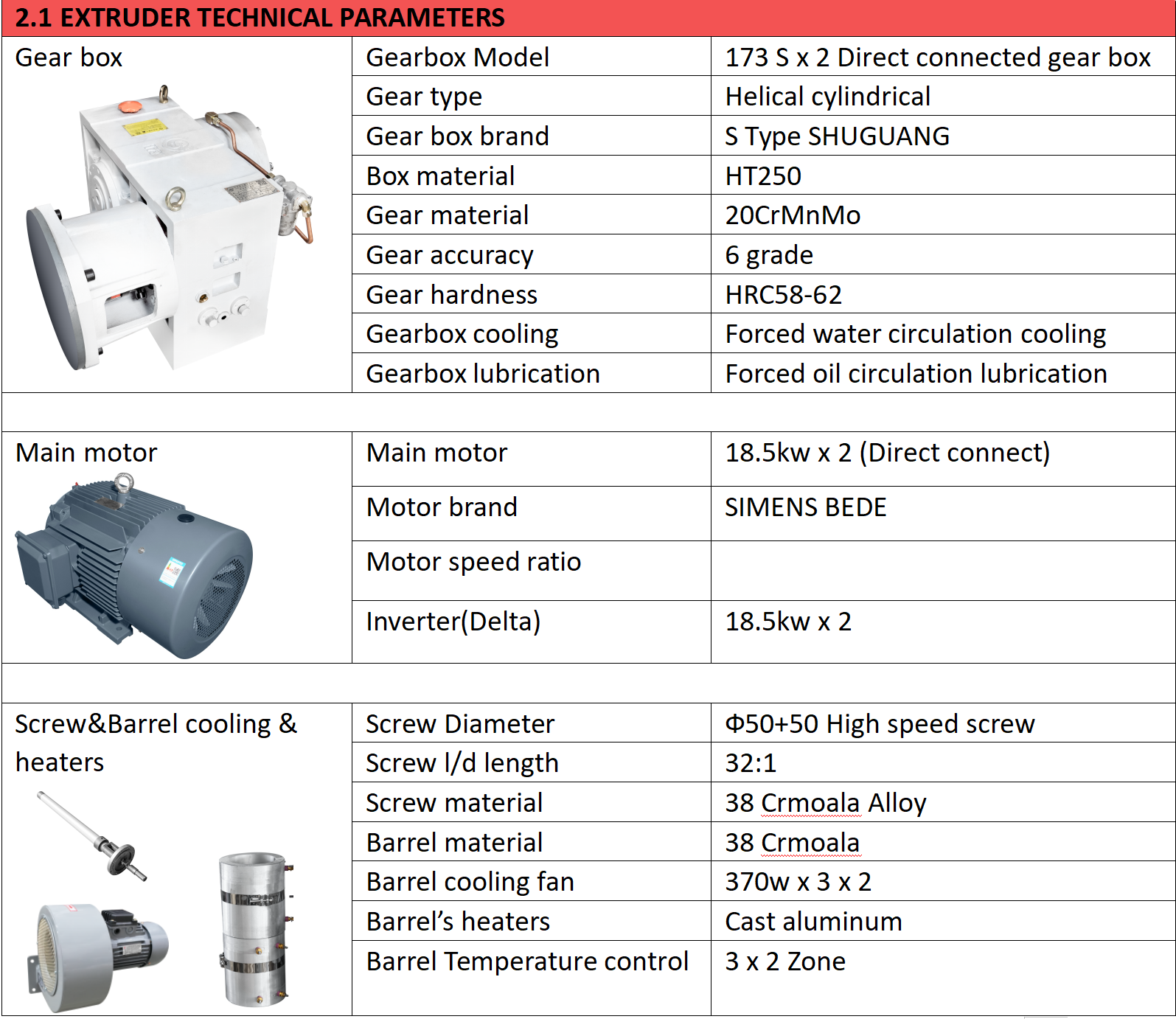

To ensure high-efficiency performance, this machine uses 38CrMoAl alloy screws and barrels with nitriding treatment, offering exceptional resistance to wear and corrosion. Key features include:

High-output screw design with superior plasticizing performance.

IBC internal bubble cooling system with ultrasonic width control, for real-time film stabilization.

Improved cooling reduces film bubble temperature quickly, resulting in faster line speeds and enhanced film uniformity.

📈 Whether you’re running large-scale production or handling high-volume orders, the ABA system delivers consistent results.

💰 Cost-Effective Film Blowing for Competitive Advantage

In today’s competitive market, material cost control is critical. The ABA machine allows you to:

Add a high ratio of low-cost filler materials to the B layer—reducing core material costs by up to 30–40%.

Maintain film quality while reducing waste and scrap rates.

Maximize long-term return on investment through lower operating costs and extended equipment lifespan.

💡 Even with a higher upfront cost, the machine pays for itself through continuous savings and higher yields.

🛍️ Versatile Applications Beyond Express Bags

While optimized for express packaging, the ABA film blowing machine is also highly suitable for:

Food packaging – Moisture- and oxygen-resistant films for shelf life extension.

Apparel packaging – Elegant film finish enhances brand appeal.

Industrial packaging – High-strength films ensure product safety during shipment.

This multi-industry compatibility helps businesses maximize equipment utilization and diversify product lines.

Learn more about express bag making machines on our website.

🌱 Future-Proof Your Production with ABA Technology

By choosing the ABA film blowing machine, you're not just investing in equipment—you're empowering your entire production process with:

Sustainable material usage

Flexible film layer configurations

Reliable performance under continuous operation

Whether you are a courier bag manufacturer, flexible packaging supplier, or industrial film converter, this system is built to deliver maximum performance and profitability.

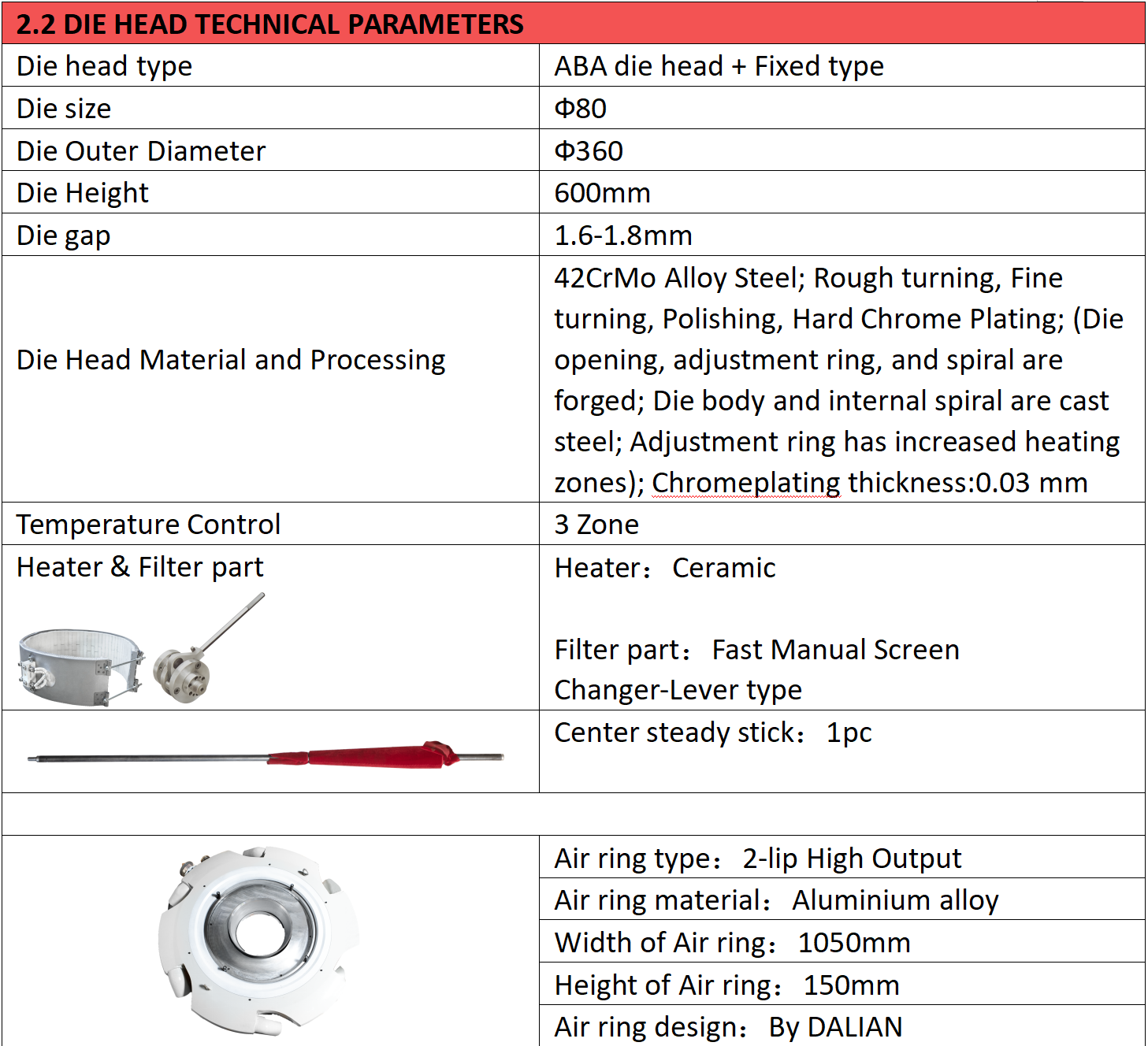

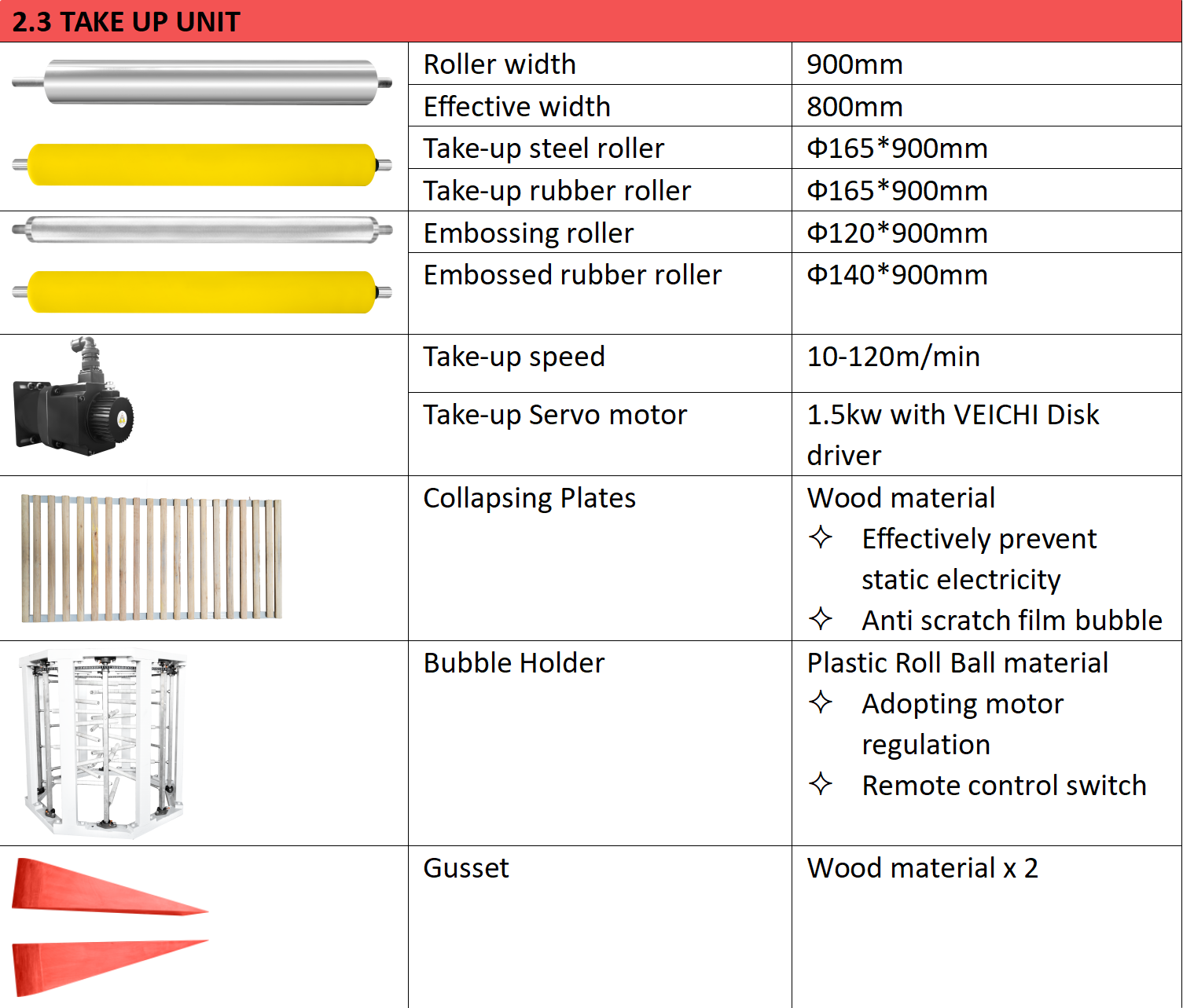

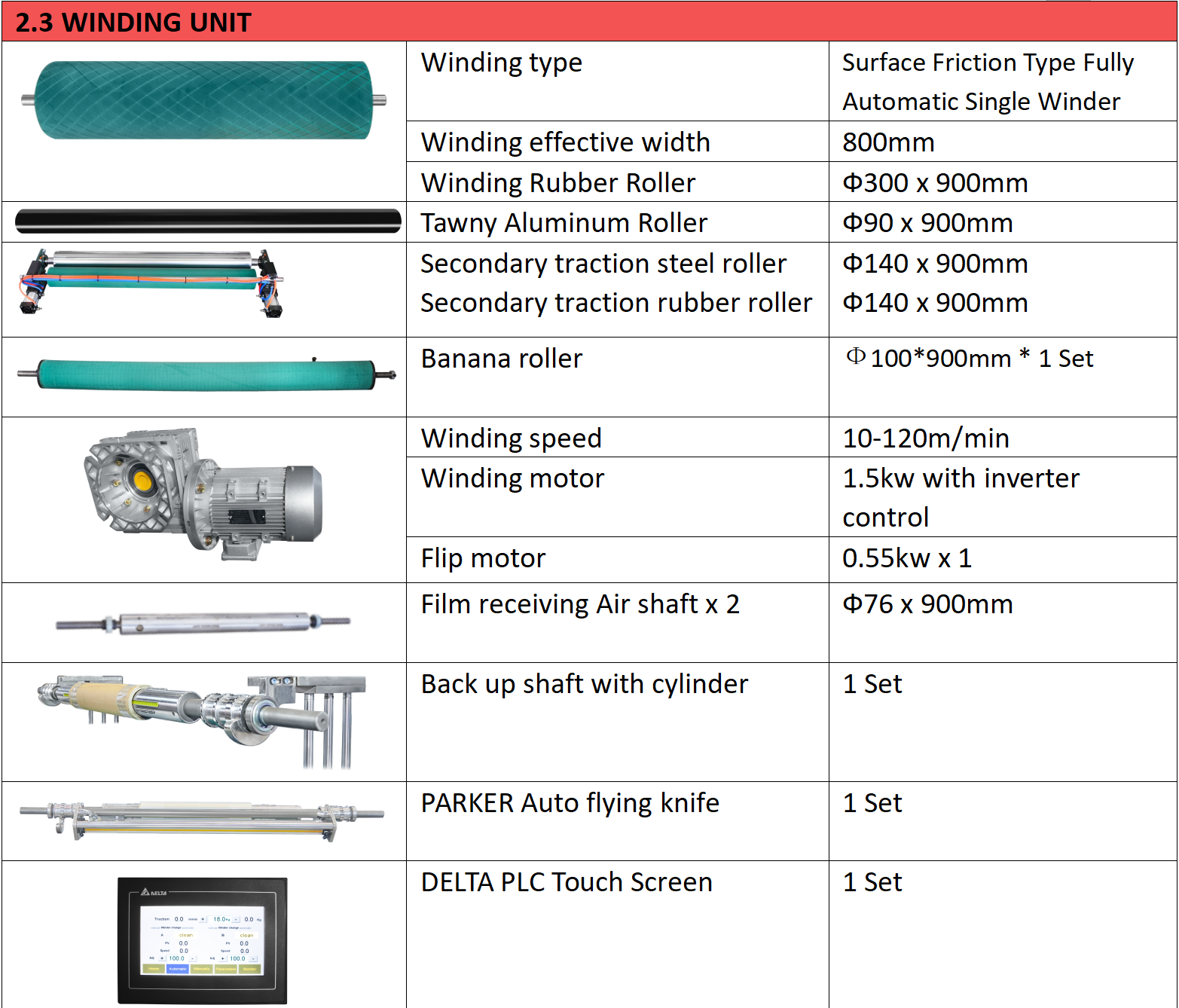

1.1 FEATURE | |

Model | ABA-900 |

Applicable Raw Materials | HDPE/LDPE/LLDPE/Fillers/Recycled |

Film Width | 200-800mm |

Film Thickness | 0.01-0.10mm |

Film Layer No. | ABA |

Max. Extrusion Output | 120kg/h |

Voltage | 380V, 50HZ, 3PHASE |

Average Power Consume | 50kw |

Machine Dimension (LxWxH) | 7500 x 3500 x 6800 mm |

Machine Weight | 4500kg |

Product Compliance | GB4455-2006 National standard |

| |

Power Supply | Three-phase 380V±5%-10%, Single-phase 220V±5%-10%, Frequency 60HZ±2% (Customized) |

Compressed Air | Pressure 0.6MPa±10%, Maximum temperature 30°C,Dust-free, water-free, oil-free |

Cooling Water | Temperature 5-10°C, Consumption approximately 200l/min |

📩 Ready to Upgrade?

Explore our full range of express bag making solutions or contact our technical team for a tailored recommendation.