High-Performance Corona Treatment System for Plastic Film and Industrial Applications

Description

🌟 Product Overview

The Corona Treatment System is an advanced surface treatment solution designed to enhance adhesion on plastic films, paper, and composite materials before printing, coating, or laminating. Using high-frequency electrical discharge, this Corona Treater modifies the material surface to improve wettability and ink bonding performance.

Widely used in blown film extrusion, flexographic printing, lamination, and coating machines, our Corona Treatment Equipment ensures consistent treatment results, high efficiency, and long-term stability.

As a leading corona treatment system manufacturer, we provide fully customizable systems to meet the specific requirements of film producers, printing plants, and packaging converters worldwide.

The Corona Treatment System is an essential surface pretreatment device designed to improve the adhesion of inks, coatings, and adhesives on plastic films, paper, and metalized substrates.

It is widely used in high-speed blown film lines, spray bonding, extrusion coating, printing, lamination, glue spreading, coating, box-pasting, and other specialized industries that require excellent surface activation performance.

⚙️ Main Features of the Corona Treatment System

Multifunctional Digital Display Panel

Equipped with a smart digital display, all operating parameters—such as power level, voltage, and working status—are clear at a glance, ensuring simple and intuitive operation.Comprehensive Protection System

Built-in safety protections include:Over-temperature protection

Over-current protection

High-voltage short-circuit and open-circuit protection

High-voltage fire-out protection

Ground wire fault protection

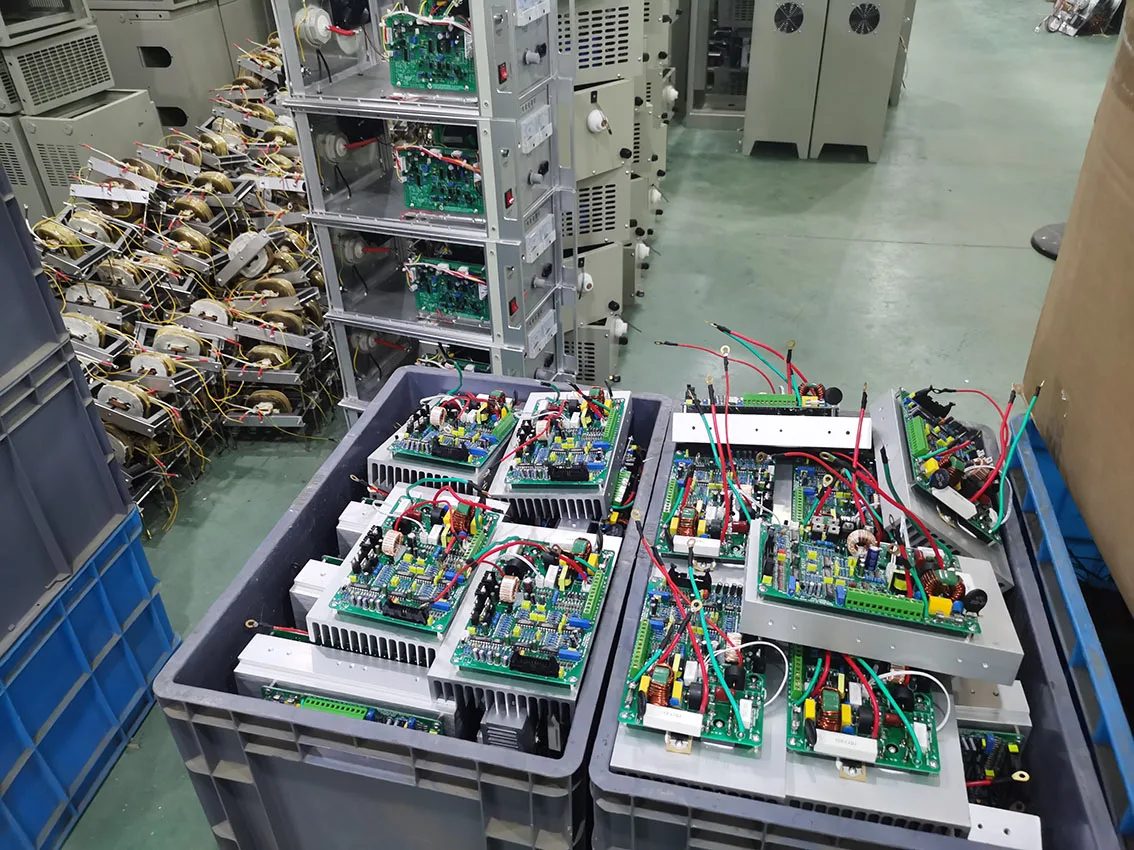

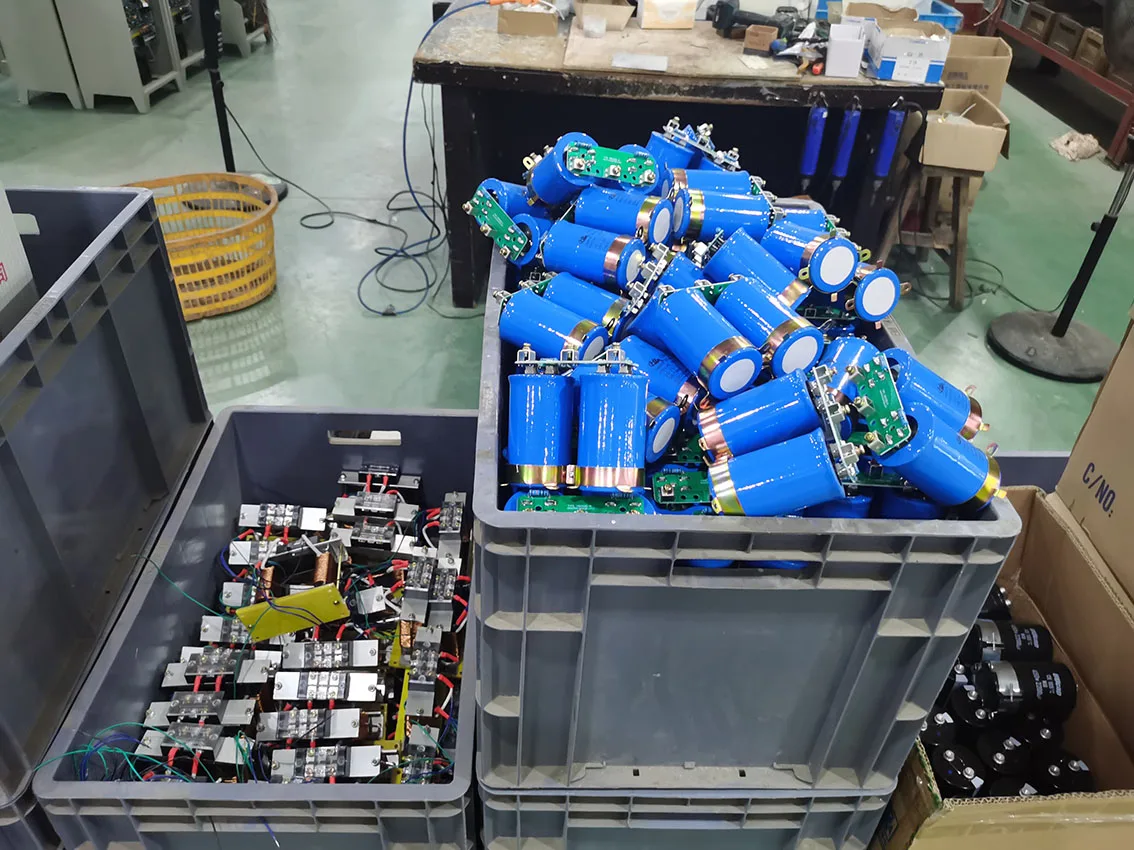

These ensure safe and stable operation under all working conditions.Imported IGBT Power Module

The system adopts imported IGBT transistor modules as the output unit, providing stable high-frequency power and supporting continuous 24-hour operation without performance degradation.Smart Sensor Interface

The control interface can be equipped with sensors to achieve automatic stop operation, open-cover safety protection, and real-time fault detection, making the system safer and more intelligent.

🧩 Applications of Corona Treatment System

The Corona Treater is specially designed for surface modification of various substrates before printing, coating, and laminating processes.

It effectively increases surface tension, ensuring strong bonding strength between the base material and the applied layer.

Typical Application Industries:

High-speed wide blown film production

Spray bonding and lamination lines

Plastic extrusion and compounding lines

Flexographic and rotogravure printing machines

Glue spreading and coating machines

Paper box-pasting and packaging lines

Plastic film pretreatment before metallization

Applicable Materials:

PE / PP / PET / PVC / BOPP / CPP / Nylon

Paper / Metalized film / Composite film

💡 Advantages of Using a Corona Treater

Enhances surface energy for better ink and coating adhesion

Prevents printing defects such as ink beading or peeling

Improves lamination strength and coating uniformity

Supports continuous high-speed operation

Reduces waste and ensures consistent product quality

🏭 Why Choose Our Corona Treatment System?

Professional R&D and manufacturing experience in surface treatment technology

Customizable electrode widths for different film sizes

Energy-efficient design with minimal power loss

Stable output voltage and low maintenance requirements

Widely used in film extrusion, printing, coating, and lamination industries across Asia, Europe, and South America