Fully Automatic High Speed Dual Channel Compostable PE Express Bag Making Machine With Glue Tape

Description

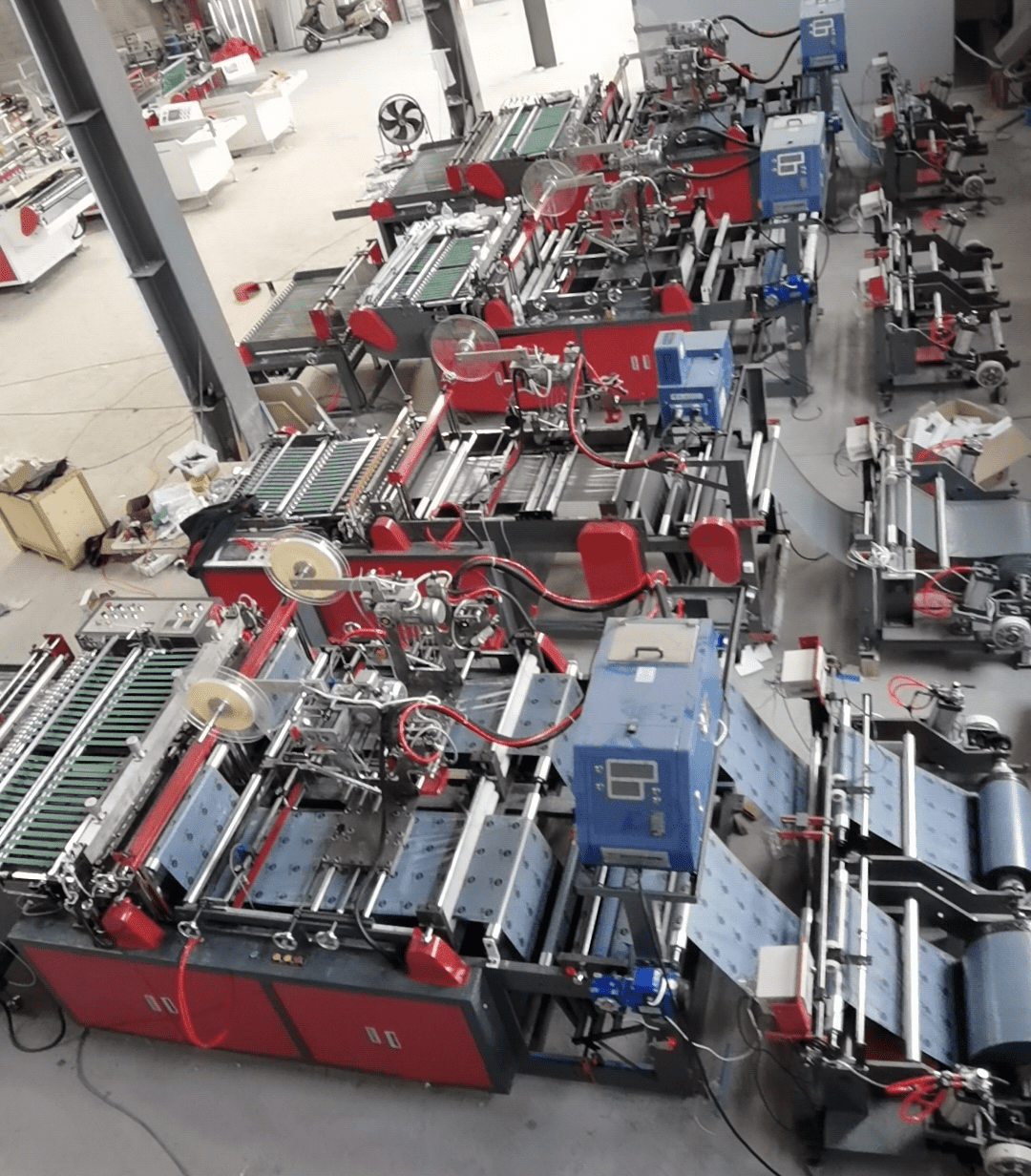

Product Introduction

This bag making machine is suitable for hot-cut edge-sealing bags of printed or unprinted LDPE, LLDPE, HDPE and other plastic materials, polyethylene (PE) plastic films. The whole machine is equipped with computer automatic length setting, automatic color mark tracking, automatic glue cutting, automatic stop when there is no material, automatic stop when there is no release film, automatic tension, etc. It is currently the fastest and most advanced express bag production equipment.

Product Specification

| Model | 1200-1300-1400mm |

Total Power (KW) | 9 |

Average Power (KW) | 5 |

Bag Making Length | 100-1000MM |

Bag Making Width | 150-550MM |

Machine Length | 6240MM |

| Machine Width | 1800-2000MM |

| Machine Height | 1800MM |

Production speed (pcs/min) | 170-350 |

Main power | 220V |

Weight(KG) | 2000 |

Applications

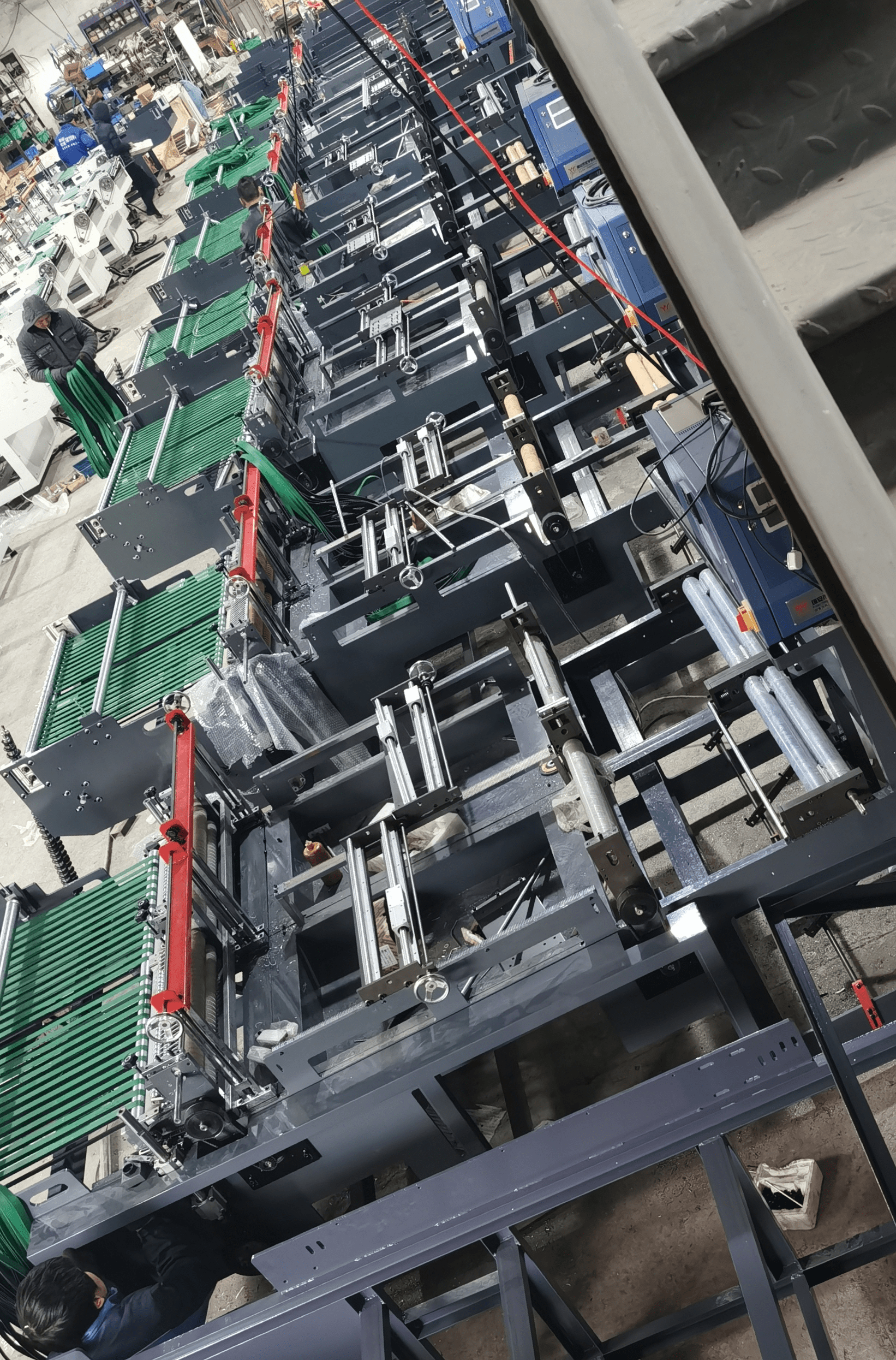

1. The whole machine adopts independently developed PLC and four servo motor system control technology.

2. Automatically set bag length, double-sided printing photoelectric eye tracking, accurate, stable, automatic shutdown when label is lost.

3. The equipment adopts one-out-two mode for material discharging, automatic counting, and can set any number of shutdown seconds and automatic feeding. Save labor and greatly improve bag making efficiency.

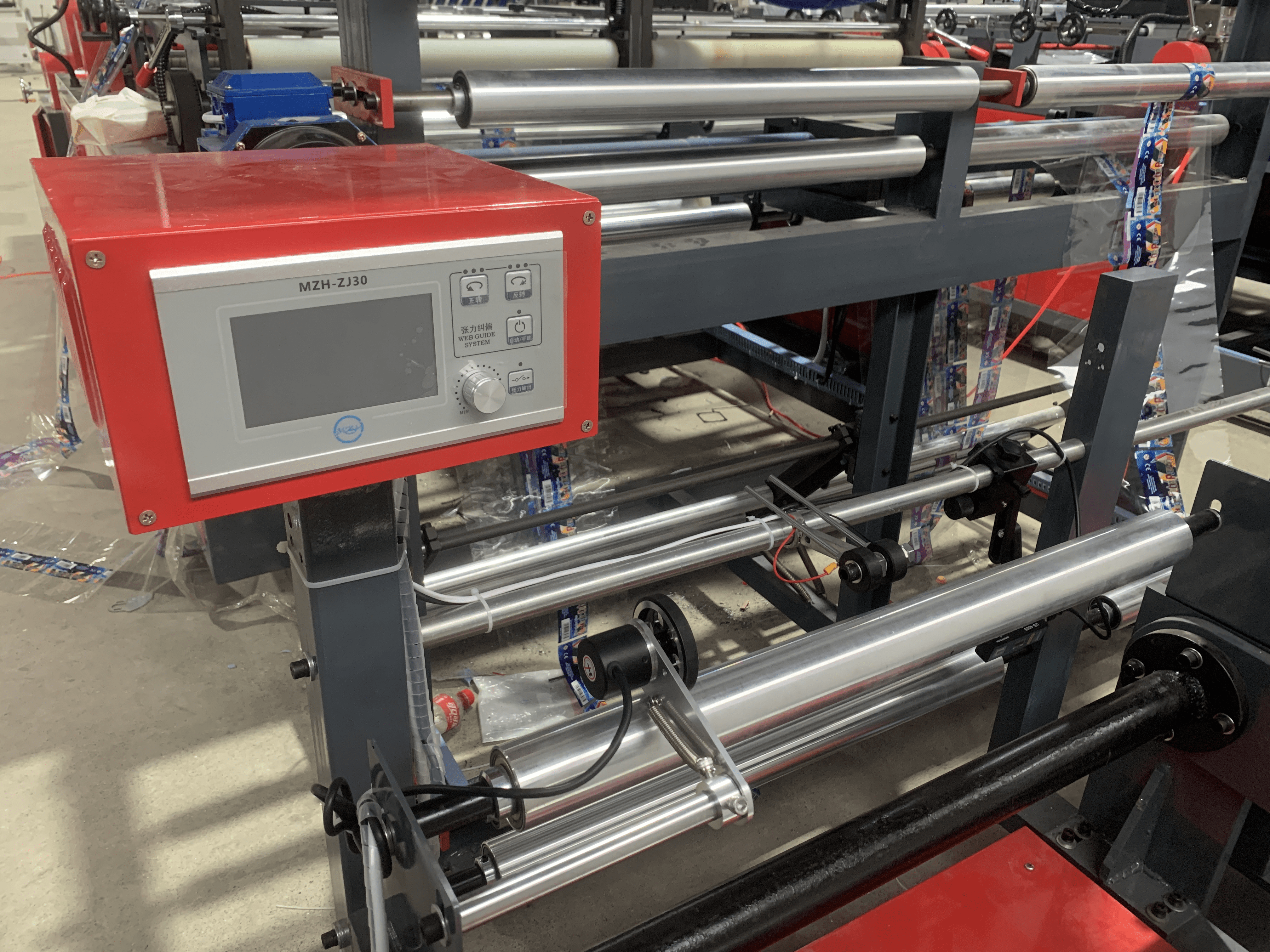

4. Fully automatic computer synchronous release film glue break rear material edge correction system control technology, release film no material automatic shutdown system, rear material no material automatic shutdown, (technical patent) bag making high speed and stability, glue break uniform.

5. The hot cutting knife is made of alloy material, which is not easy to deform, not easy to stick to the material, and high temperature resistance. The intelligent temperature control system has the advantages of firm, flat and beautiful bag mouth sealing, temperature adjustment range: 0-450℃.

6. Release film and rear feeding analog quantity synchronous control.

7. Automatic pneumatic feeding edge correction: The tension control method is the magnetic powder brake system, and the edge correction control system adopts U-shaped ultrasonic laser sensor without shaking and adjustment. Automatic shutdown without material A.B mode (A touch shutdown, B calculation roll diameter shutdown).

8. Mechanical arm type adjustment device, you can adjust it while cutting the food bag while sitting. Easy and not tiring.

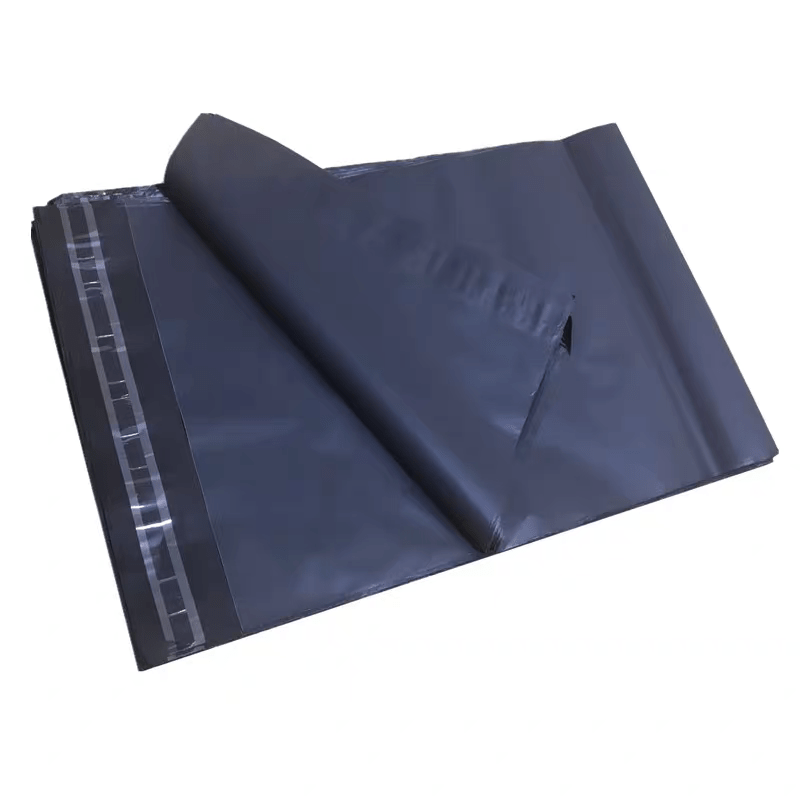

Bag Sample