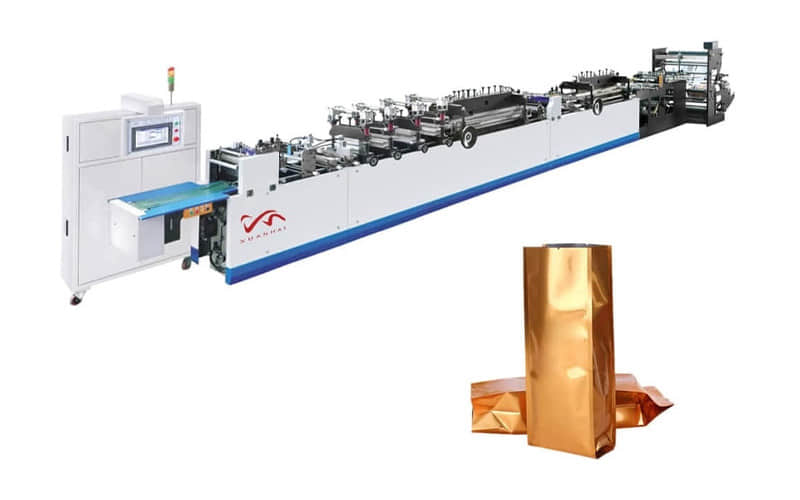

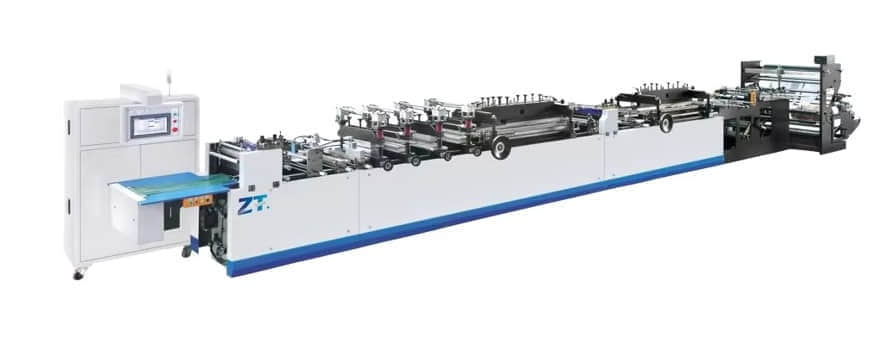

Fast Speed High Quality Four Side Sealing Pouch Making Machine

Description

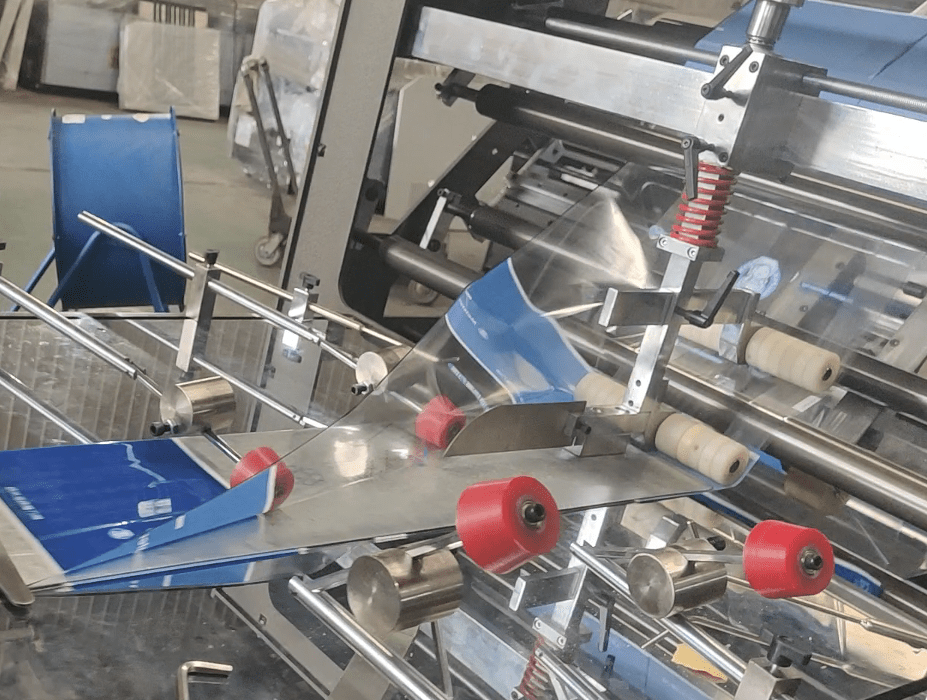

1) Unwinding adopts double photoelectric correcting deviation.

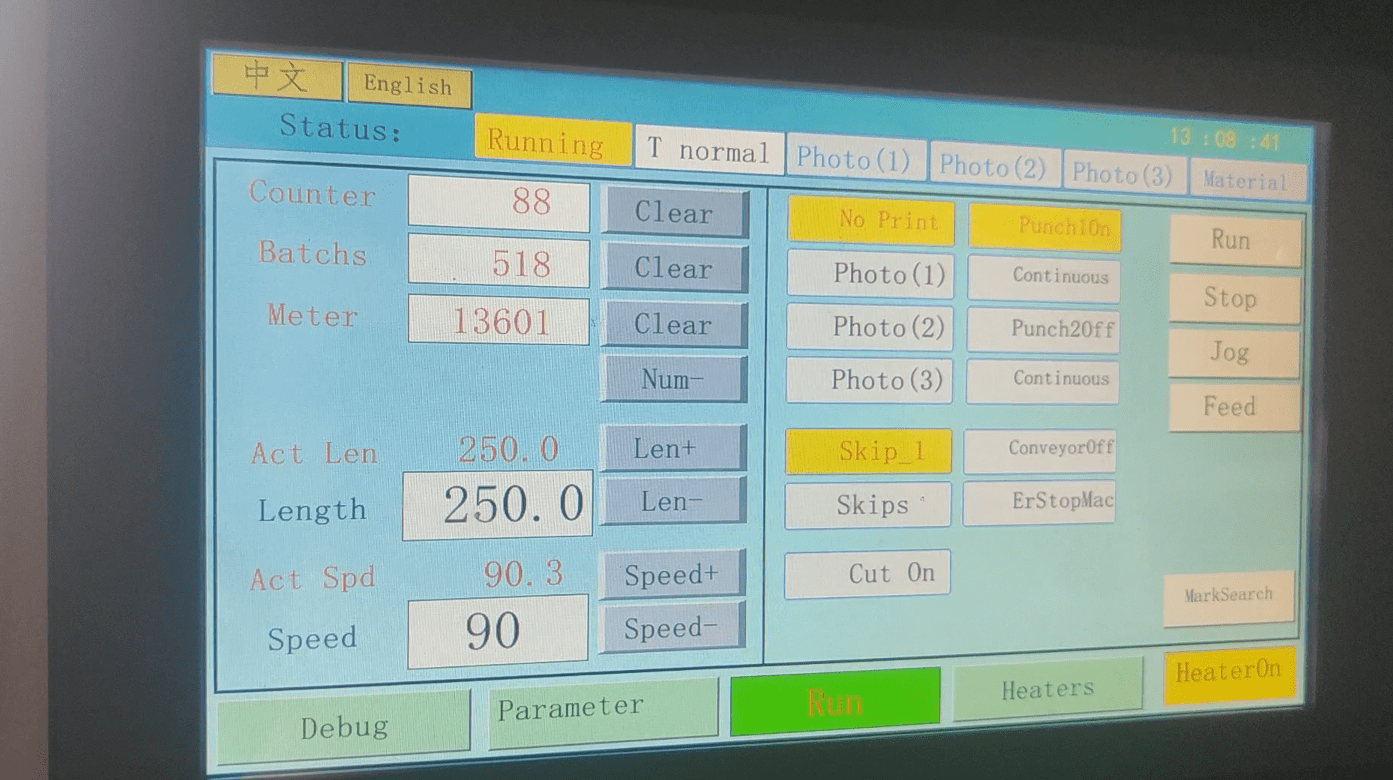

2) Micro-computer control,color screen display,easy to operate.

3) Out device of machinery transmission,imported frequency governor,operate steady

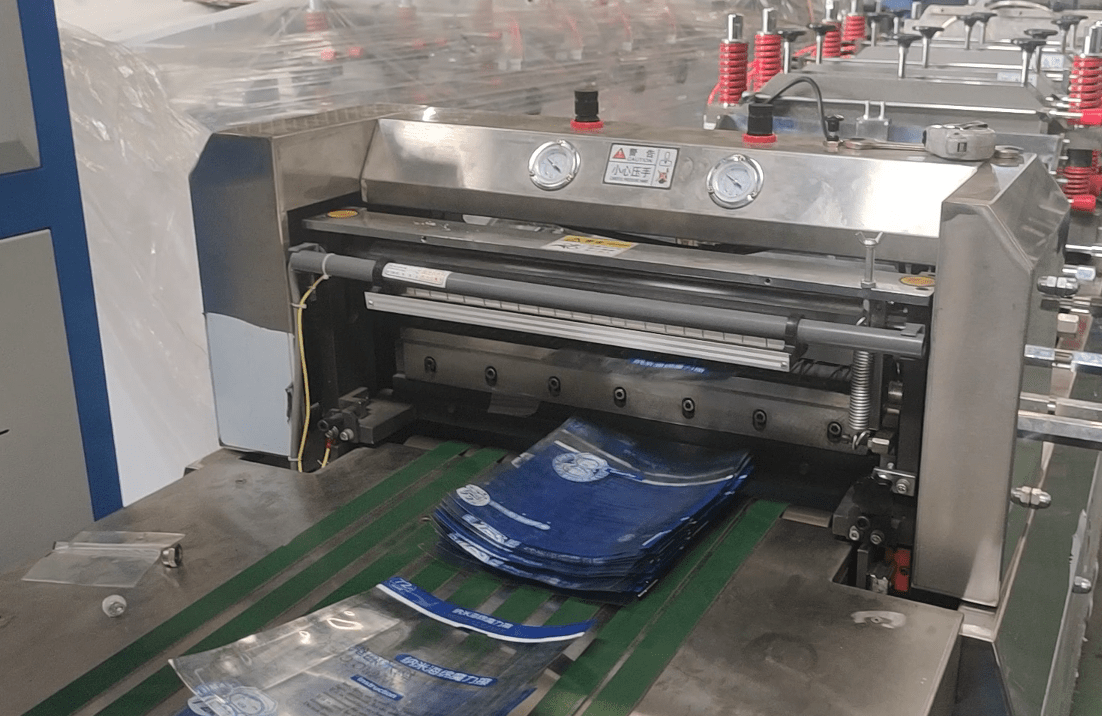

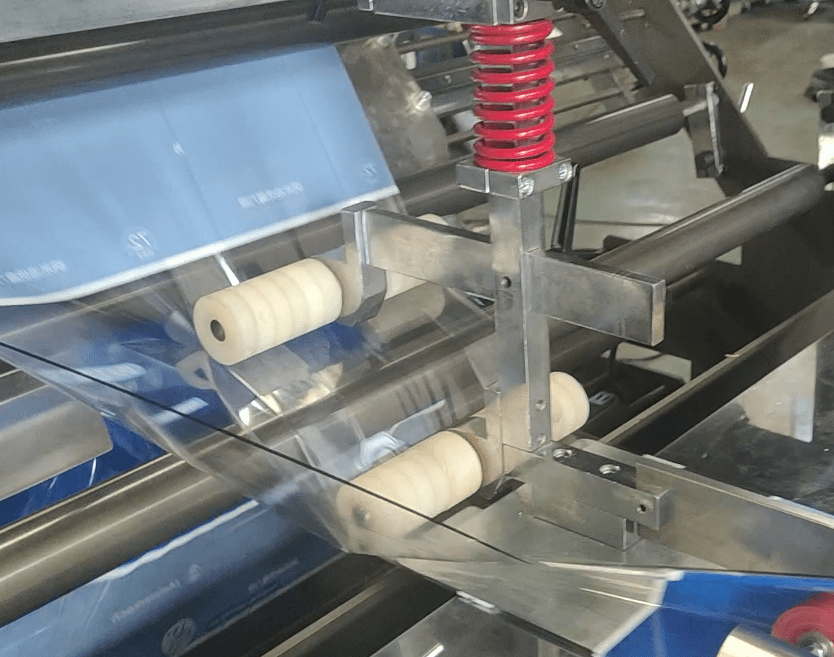

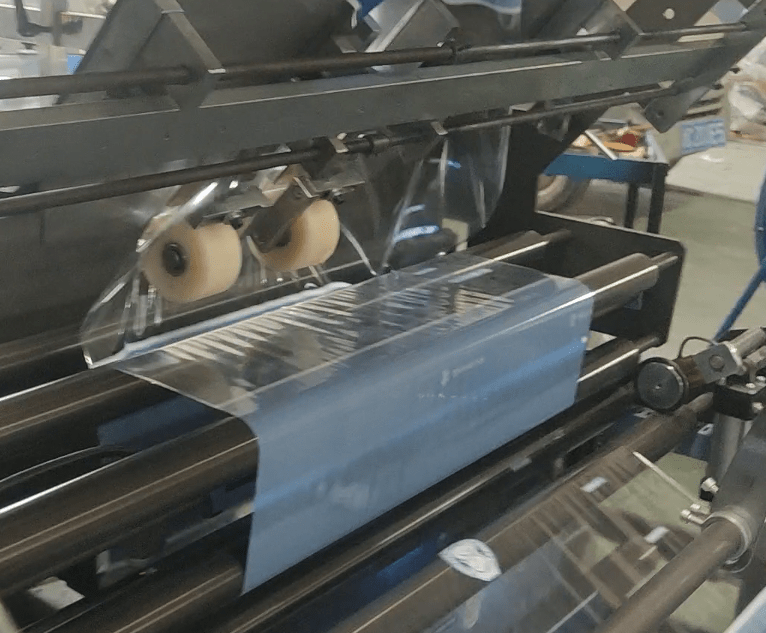

4) Double-step pull(option:servo motor),photoelectric tracking

5) Pneumatic blade and hole punching device,easy to operate and exactly position

6)counter:quantity,batch accumulation,pre-set available,6 times sending function

6)counter:quantity,batch accumulation,pre-set available,6 times sending function

| Machine function | High-speed intermediate sealing |

| Width of making bags | 480mm |

| Maximum material feeding speed | ≤35 m/min (depending on the type of material bag) |

| Maximum roll size | 850×1050 mm (φ×FW) |

BOPP, COPP, PET, PVC, Ninon and other plastic composite films, multi-layer co-extruded films, aluminum-coated composite films, paper-plastic composite films, pure aluminum foil composite films.

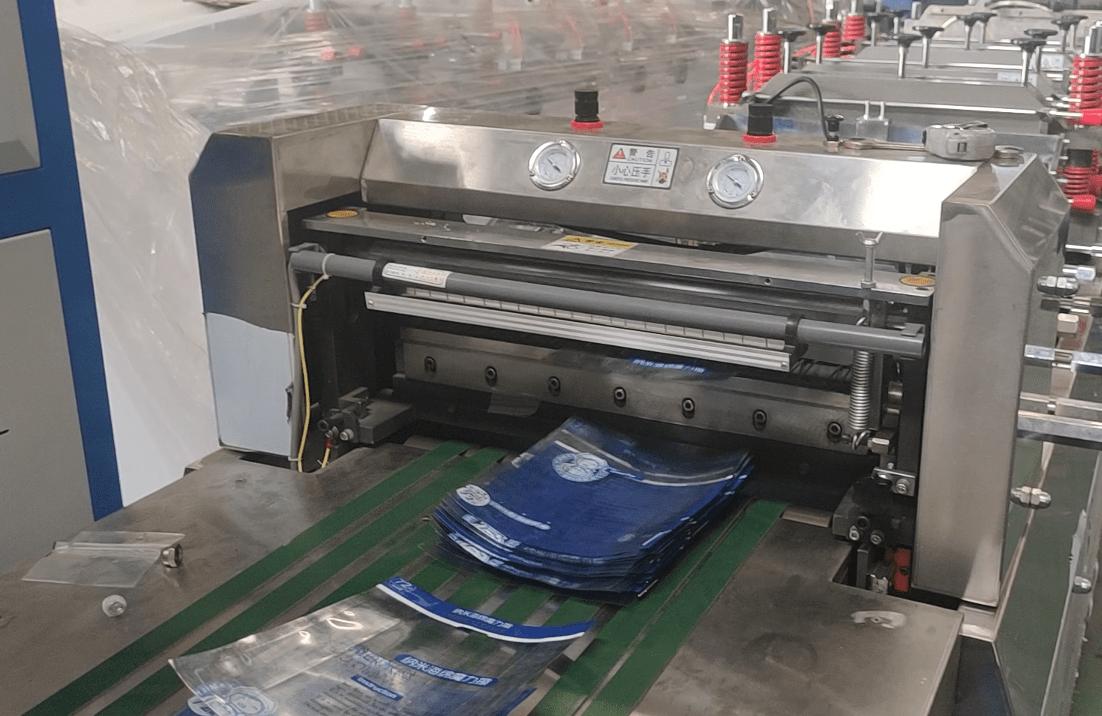

Finished product