Automatic Non Woven Fabric Quality Inspection Rewinding Machine

Description

Nonwoven Fabric Quality Inspection Machine

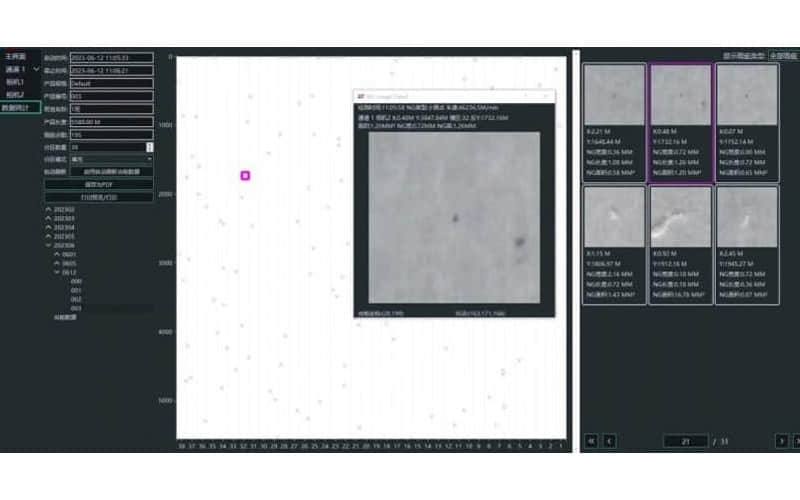

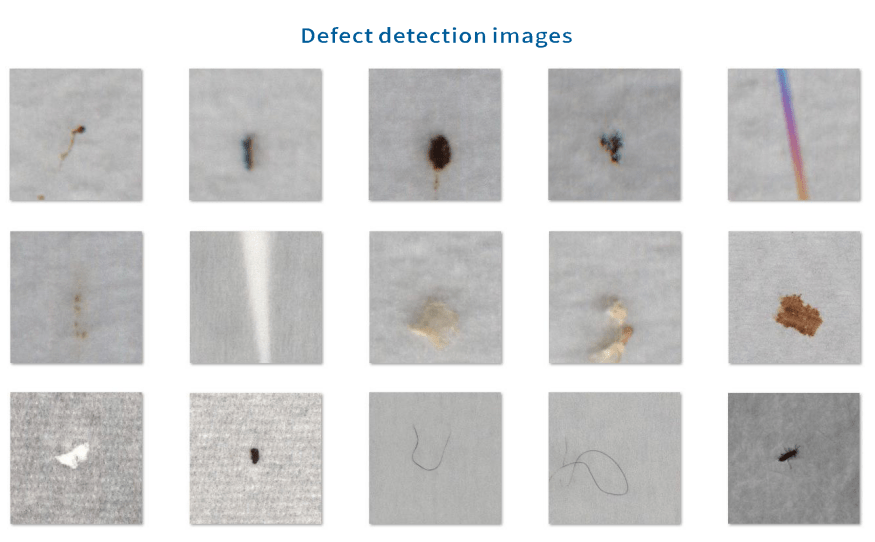

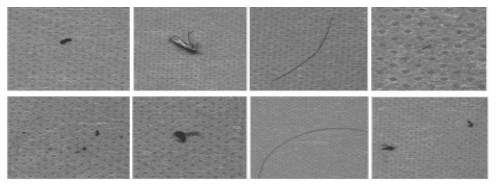

Edge computing-based online quality inspection systems use a CCD camera to convert the target object into an image signal. Suitable for roll rewinding machines, it detects defects such as stains, lint, colored particles, oil stains, cotton fibers, patches, color spots, colored fibers, and hair on non-woven fabrics.

Nonwoven Fabric Inspection

The surface of nonwoven fabrics is inspected using a CCD camera to ensure the quality of raw materials, guaranteeing 100% pass inspection for all products. This inspection system can promptly detect product defects during production and automatically classify and judge the information images. This information can be used to quickly locate defect locations for repair or slitting and sorting during subsequent cutting and rewinding processes, preventing defective products from leaving the factory and thus ensuring the quality of nonwoven fabric materials, especially suitable for the medical and hygiene industries.

Inspection Objects: Spunbond, spunlace, thermally bonded, chemically bonded, hot-air woven, gauze, and other nonwoven materials

Inspection Speed: Supports a maximum production speed of 800 meters per minute

Inspection Width: Any width (multiple cameras can be combined)

Inspection Accuracy: 0.1-0.5mm² (accuracy can be designed according to user requirements)

Inspection Contents: Oil stains, black spots, insects, hair, impurities, foreign objects, white cotton knots, cotton clumps

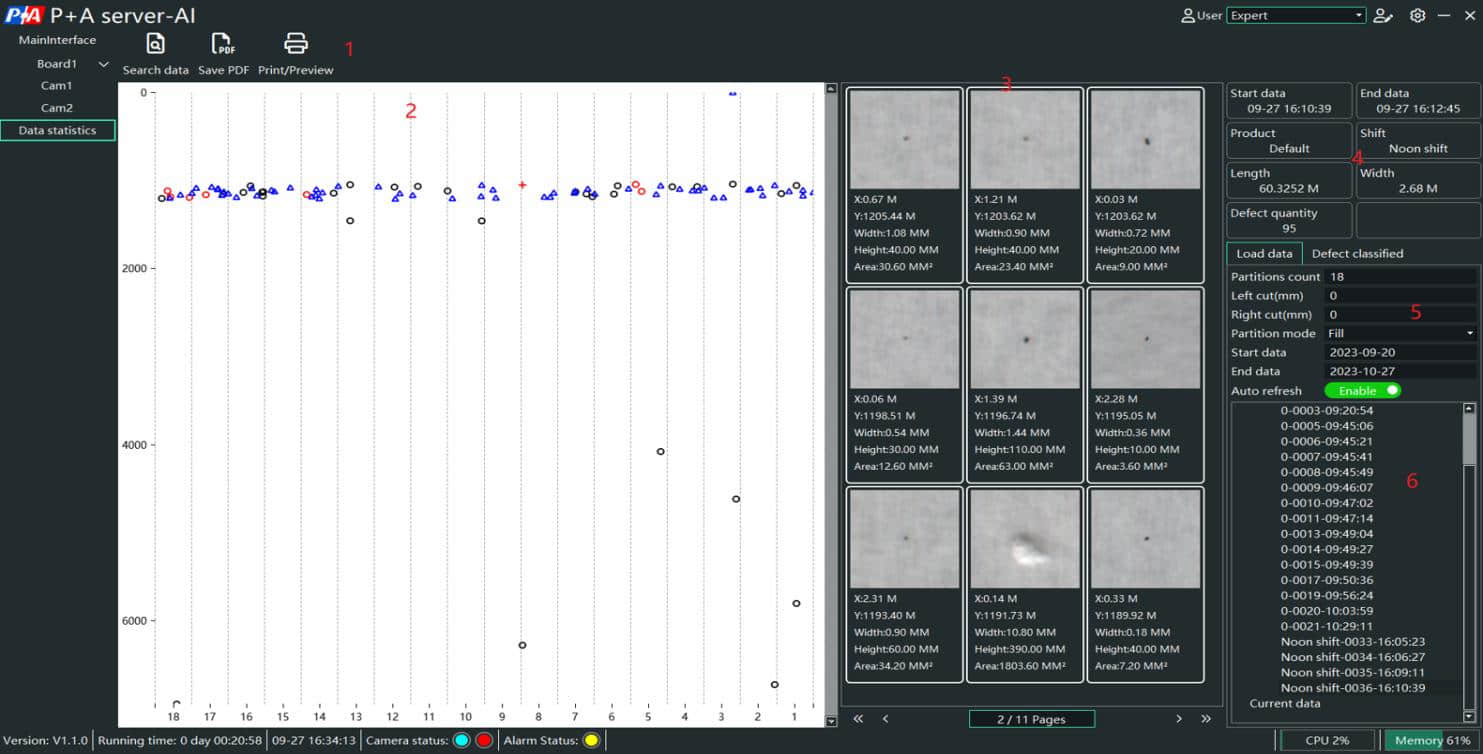

Result Processing: Machine alarm, real-time display of defect images, recording and saving defect coordinates, online labeling

VS 818 Series- Surface Inspection System

Applied with latest FPGA detection technology,VS818-series vision system accurately identifies colorful stains on material surface by ultra-high-resolution line-scan color cameras in high-speed production.

It can effectively eliminate false detection caused by flying dirts and make precise defect classification through Al deep learning algorithm。

1、More Flexible Installation: The cabinet of the edge computing online table quality inspection system can be installed near the inspection machine and connected to a remote control station via network cable, avoiding interference from long cables.

2、Rollup Charts and Reports: The UI supports more than 20 AI defect categories, displayed in a rollup chart. Different types of defects are displayed in different colors and shapes on the rollup chart. Clicking on a defect in the rollup chart connects to the corresponding defect chart on the right, displaying all defects (NG) in the current rollup. Clicking on a defective image connects to the corresponding rollup chart position on the left and can output and print a defect report.

3、Strong Expandability: The system uses an edge computing template as the main processing module. One edge computing template can connect to two cameras, and one industrial PC (CPU I5 or higher) runs the UI, with both connected via gigabit network. The system can support expansion to up to 10 boards, and one industrial PC can connect to a system of 20 cameras.

4、Self-diagnostic function: This detection system has multiple self-diagnostic functions, providing software and hardware security protection.

5、Periodic defect setting: Defects caused by production equipment failures. By setting this parameter (related component dimensions), the system can automatically analyze which equipment is malfunctioning and automatically provide relevant alarm prompts to the user, enabling periodic defects to be detected and handled in their early stages.

Field installation of inspection system