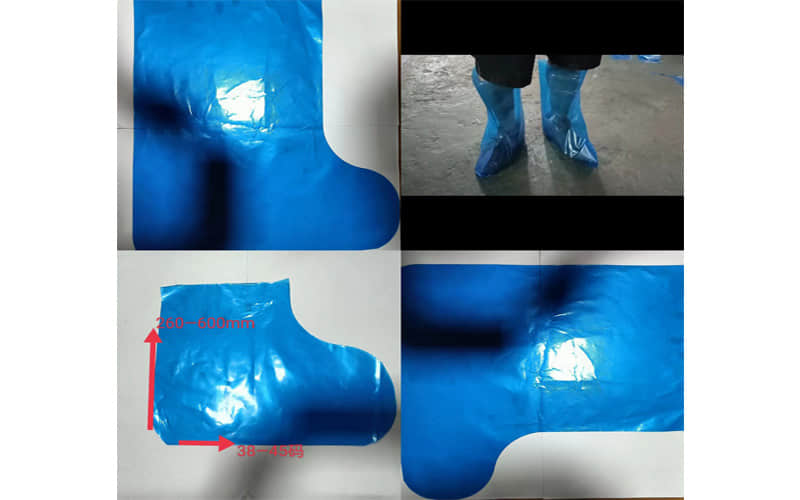

PE Disposable Plastic Boot Cover Making Machine 38-45 Size Waterproof

Description

This machine is suitable for producing disposable plastic boot covers, widely used in medical, food hygiene, and aquaculture industries, and is easy to use.

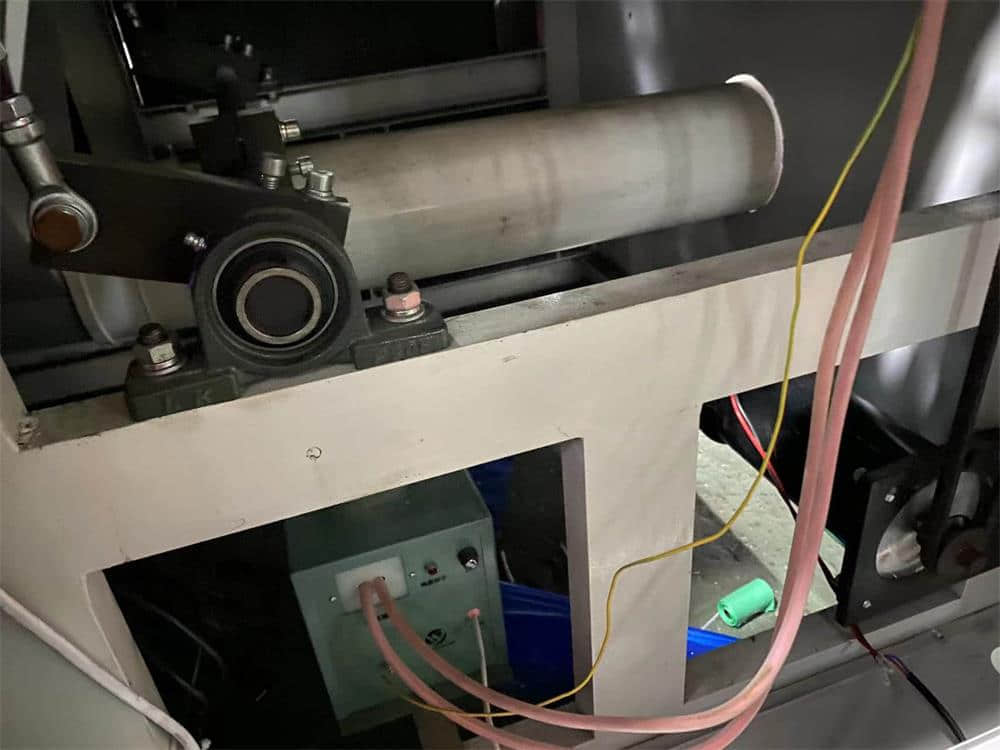

1. The entire machine is controlled by a microcomputer, with a stepper motor for material feeding (a servo motor control system is optional).

2. Arbitrary fixed length and step length photoelectric tracking ensures accuracy and stability. Automatic stop upon label loss; material feeding is photoelectrically controlled.

3. Automatic counting with a pre-set counting alarm.

4.High-precision molds are used; boot cover molds can be customized according to customer sample dimensions.

Technical Parameters:

Effective cutting width: | 300--450mm |

Effective cutting height: | 260—600mm |

Effective cutting thickness: | Plastic 0.01mm-0.1mm |

Machine speed: | 30-50pcs/min |

Cutting accuracy: | ±0.2-0.5mm |

Total machine power: | 5.5KW |

Total machine weight: | 800KG |

Dimensions: | 3000×1400×1500mm |

What Make Us Different

|  |

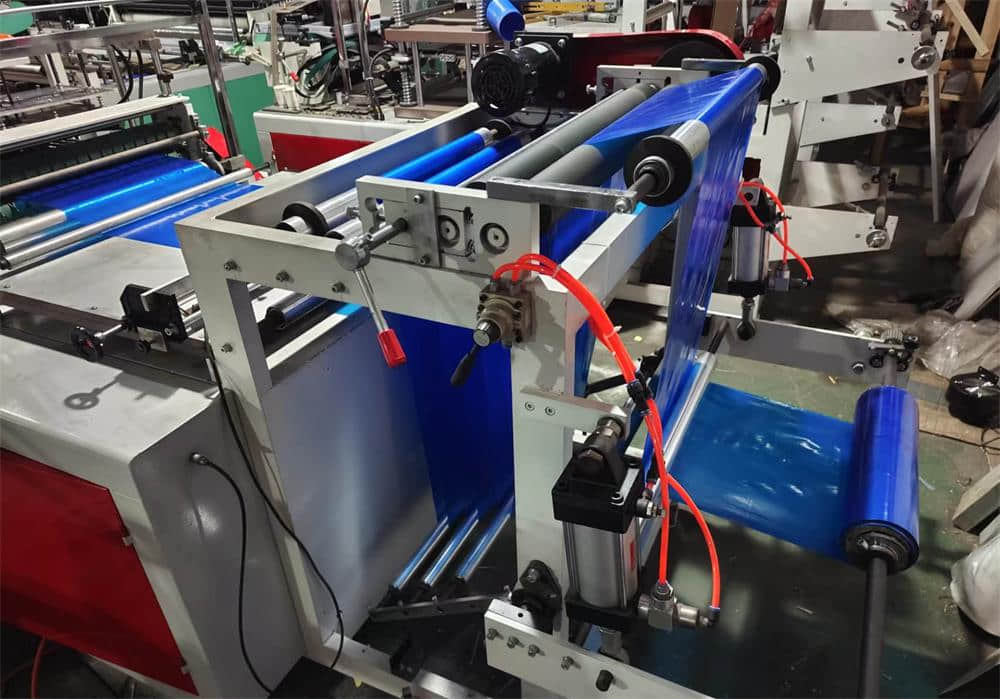

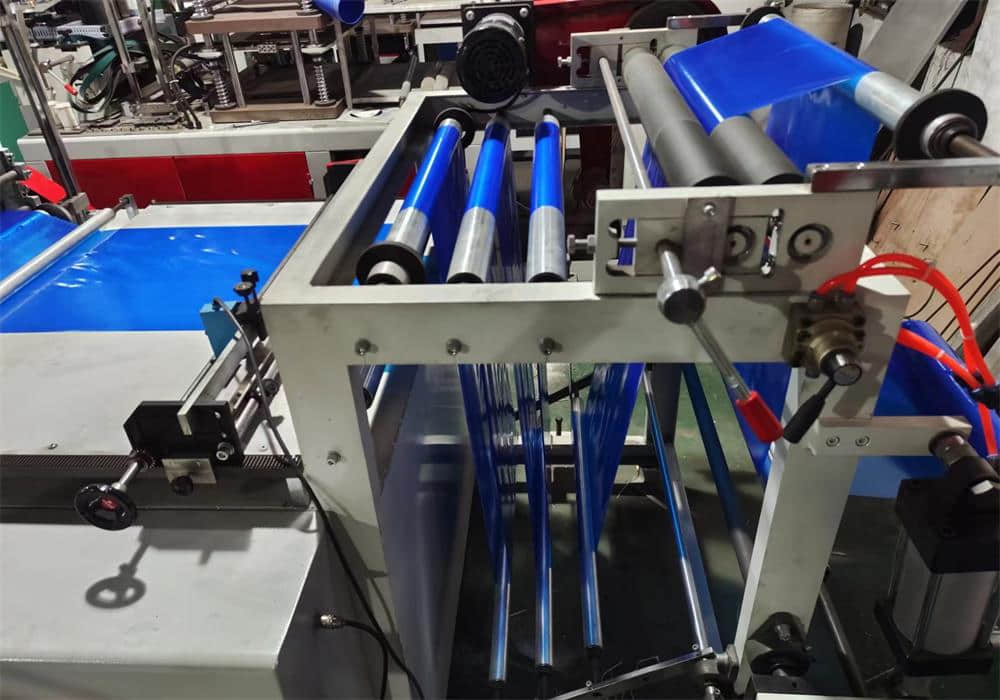

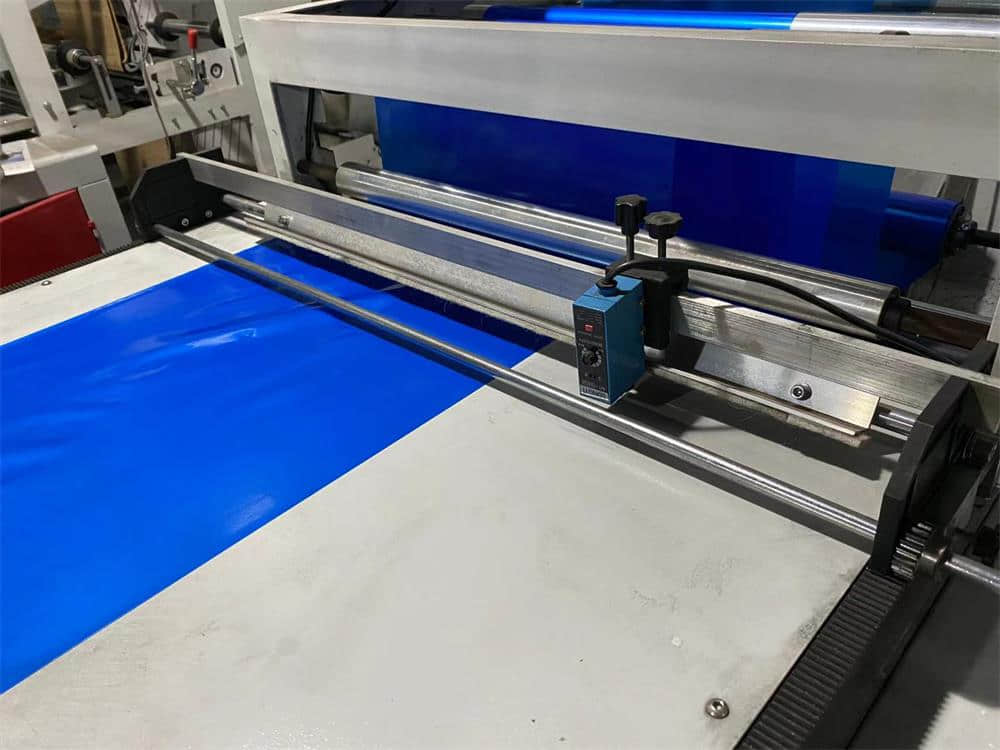

| Raw material feeding rack section | |

|  |

| Feeding | Photoelectric sensor |

|  |

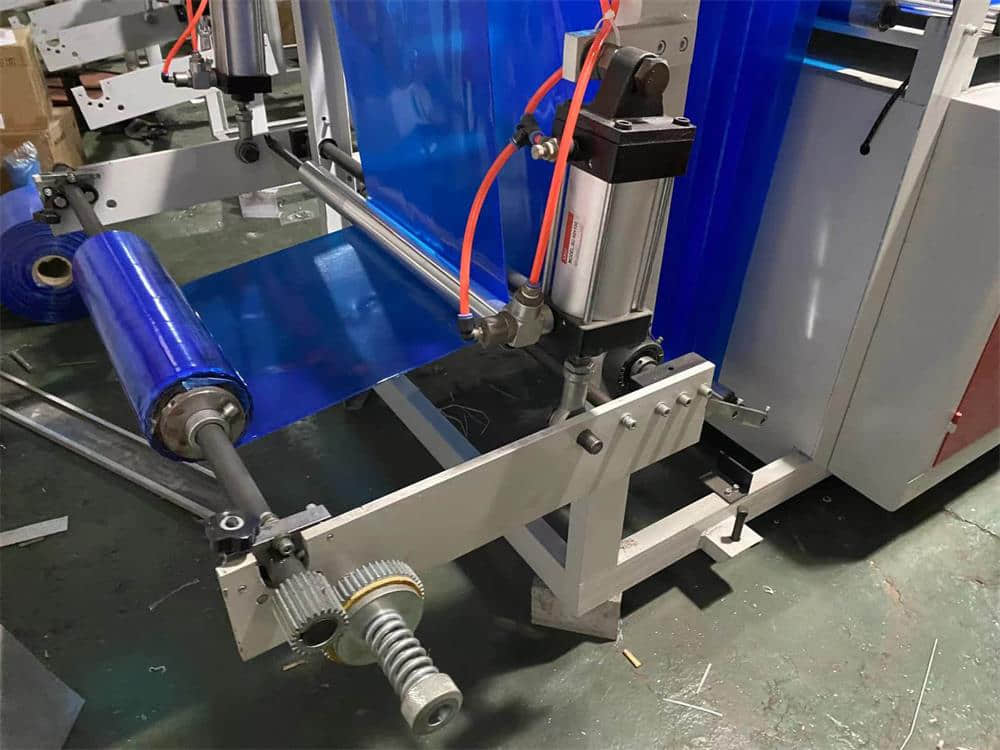

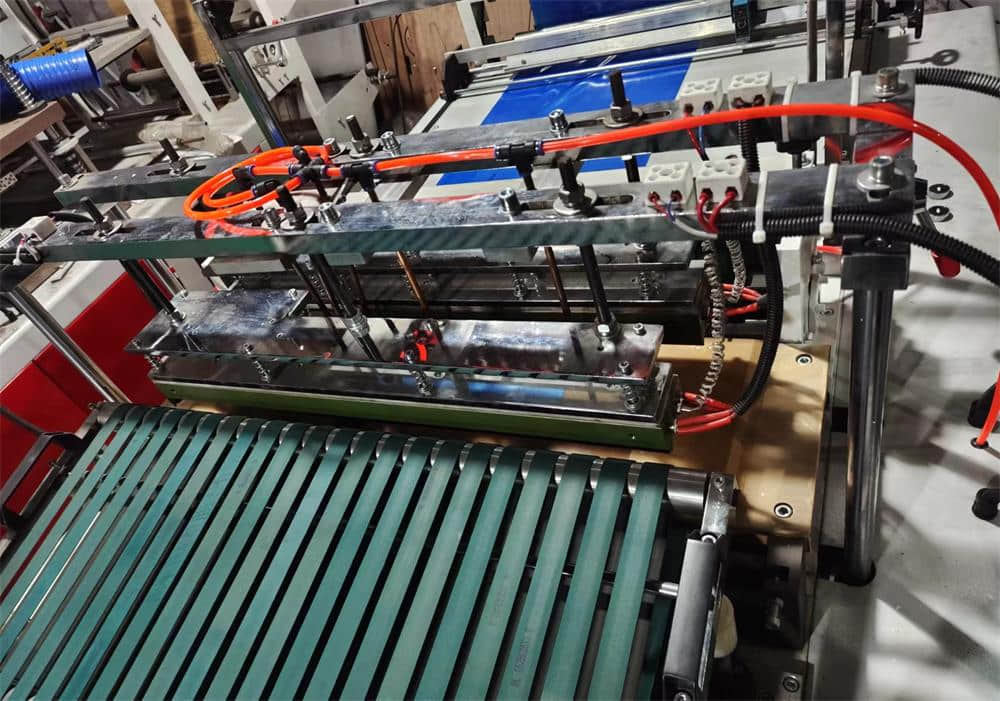

Boot cover mold section | |

|  |

| Boot cover scrap discharge outlet | |

|  |

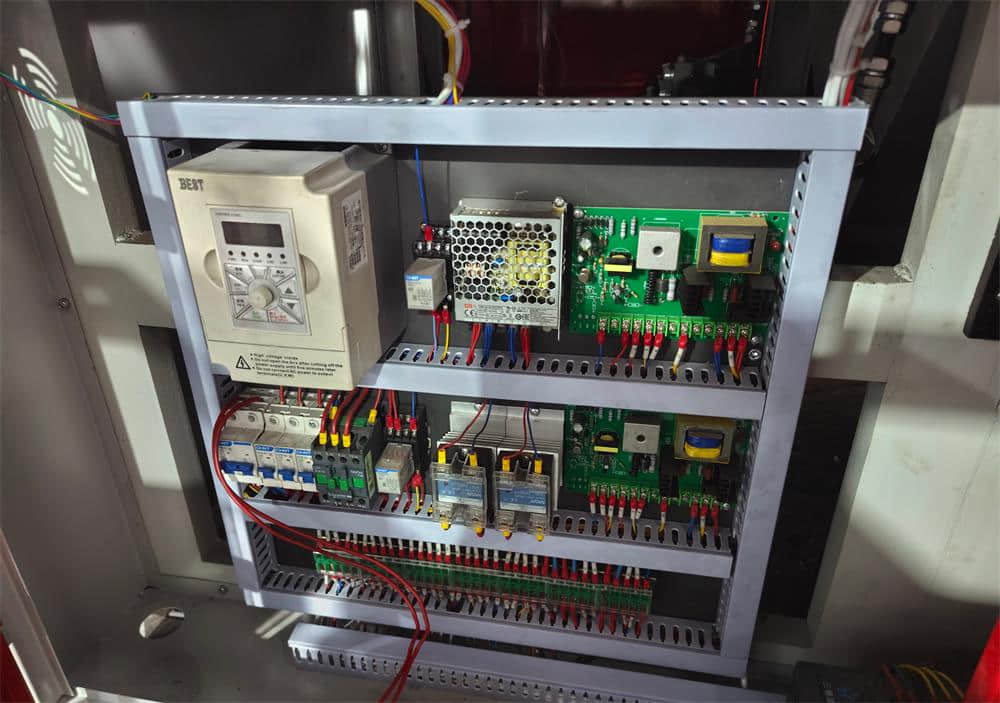

| Touchscreen control panel | Machine electrical box |