Fully Auomatic Rolling Star Sealing Garbage Bag Making Machine For Trash Bag With Non Stop

- Fully Automatic Non stop Operation

- Rolling Star Sealing Garbage Bag

- Double Lines Working

Description

High-Efficiency HDPE/LDPE Rolling Star-Sealed Garbage Bag Making Machine

This fully automatic bag making machine is designed for producing perforation coreless rolling garbage bags, star-sealed trash bags, and flat-sealed waste bags. It is specially engineered for 8-fold point-off continuous-rolled L-type HDPE/LDPE bags, widely used in supermarkets, vegetable packaging, and waste disposal. It also supports the production of eco-friendly biodegradable bags, including PLA, PBAT, cornstarch, and CaCO3-based bags.

Key Advantages:

✅ Multi-Function Design – Produces coreless rolling garbage bags, star-sealed trash bags, and flat-sealed waste bags, meeting various market demands.

✅ Dual Unwinding System – Double bag film roll unwinding structure enhances production efficiency.

✅ Folding Unit – Equipped with two sets of folding systems to ensure precise folding and compact rolling.

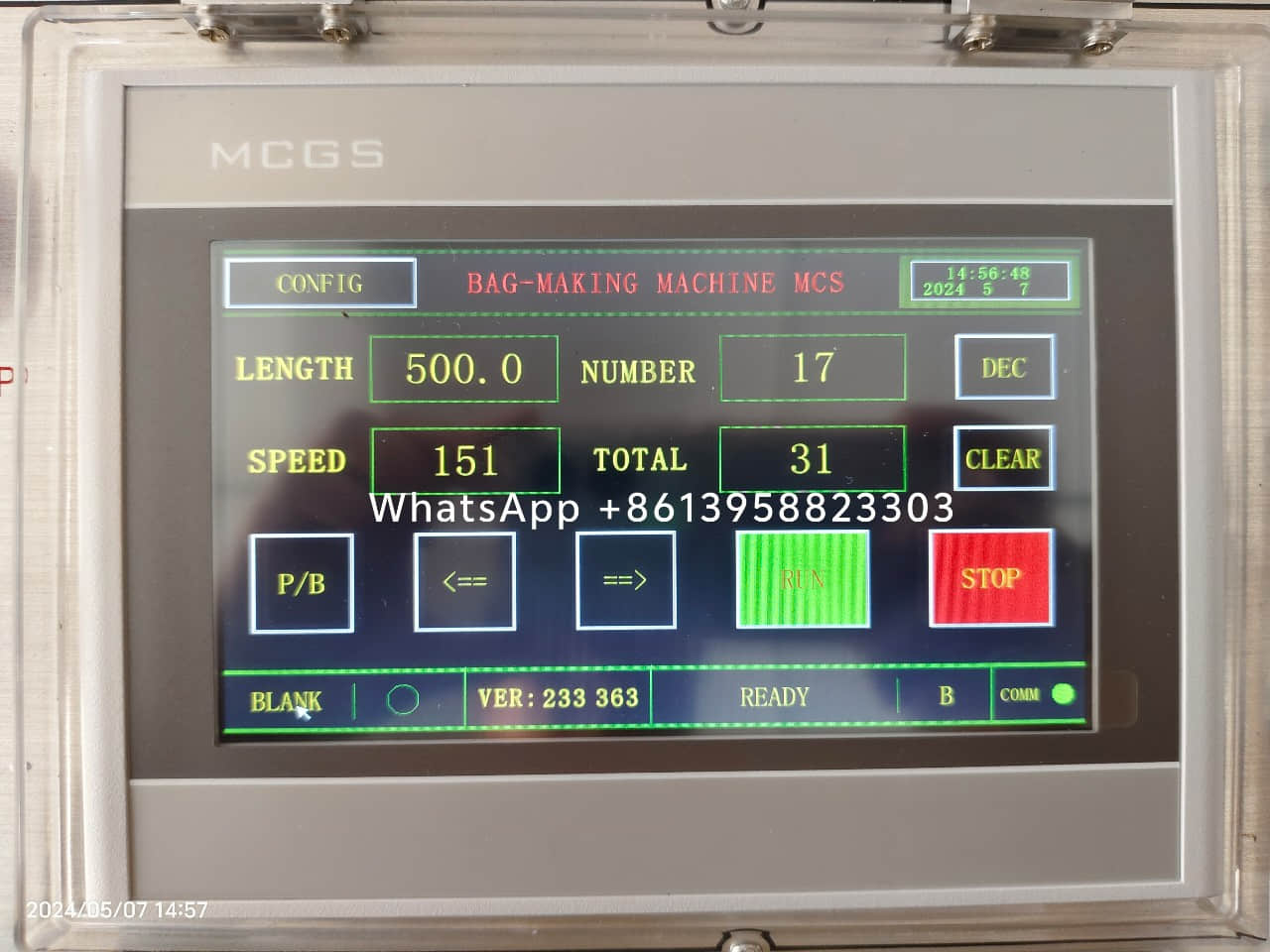

✅ Advanced Computer Control System – Includes automatic length setting, error detection, and alarm functions for improved precision and minimal waste.

✅ Photocell Tracking & Printing Alignment – Color mark tracking photocell ensures precise positioning of printed patterns, preventing misalignment.

✅ Automatic Rewinder & Roll Change System – Features an automated roll rewinding and changing system for continuous, high-speed operation.

✅ Precision Sealing & Cutting – Strong heat-sealing technology ensures durable, leak-proof garbage bags with consistent quality.

✅ Smart Automation & Safety Features – Equipped with Taiwan Delta inverters, digital temperature controllers, automatic counting, and alarm system to optimize production and reduce manual labor.

This high-performance rolling garbage bag making machine is the ideal solution for waste bag manufacturers, offering automated, high-speed production with precise sealing, cutting, and rewinding. Perfect for producing perforated roll trash bags for supermarkets, household waste disposal, and biodegradable packaging.

🚀 Boost your production efficiency with our advanced garbage bag making machine! Contact us for more details.

Technical parameters

| Model |

| VOLTAGE |

| Suitable materials |

| Producing length |

| Producing width(two lines) |

| Final products width |

| Producing width(one line) |

| Final products width(one line) |

| Producing speed |

| Total power |

| Film of thickness |

| Max. sealing layer |

| Weight |

| Overall size |

Main parts brand | |||

More machine pictures

| |

Touch screen controlCan set bag length,speed,batch | Double unwinder rollers |

|  |

Color mark trackingMake colored bags | Two rolls bag auto come out |

|  |

| Folding device to fold your bag | |

|  |

| |

Two copper sealing knives to seal and perforation cut the bag | |

| |

IMPROVE MACHINE ALL THE WAY ONLY OUR MACHINE HAS BLOWER FOR ELECTRIC BOX TO COOLING THE TEMPERATURE NICE PAINTING FOR THE MACHINE STRUCTURES | |

|  |

| HIGH QUALILTY PARTS PROCESS AND INSTALLMENT THAN OTHER SUPPLIERS | |

| |

|  |