Multi functional Heavy-duty Three Side Sealing Zipper Pouch Bag Making Machine

- Model:500mm,600mm

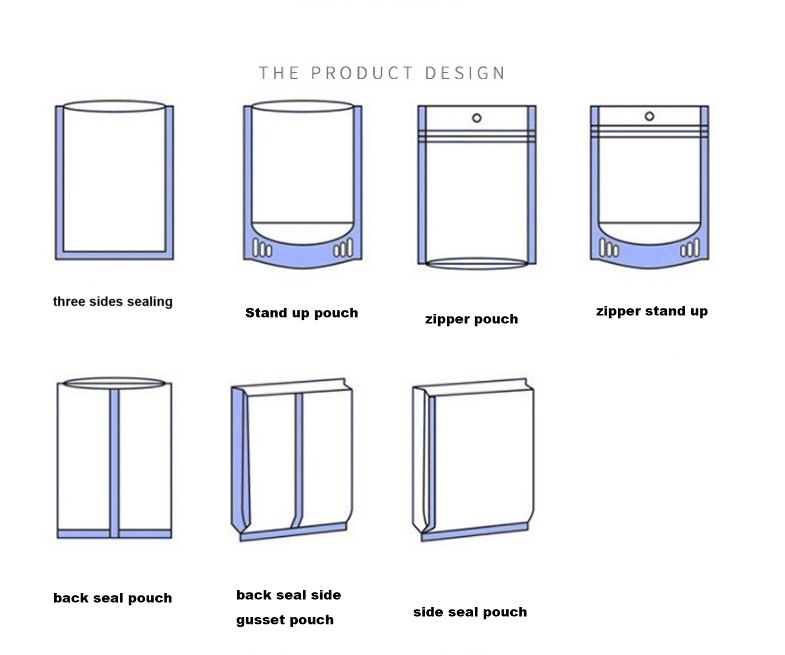

- Bag type:Centre sealing pouch bag,three sides sealing bag,zipper stand up pouch

- One machine make all pouches

Description

The multifunctional three edge sealing bag making machine is a heavy-duty bag making equipment with a high degree of automation, mainly used for making flat or tubular plastic bags. Through processes such as heating, pressure, and cooling, the plastic film is hot melted and sealed at the three edge sealing to form the desired plastic bag.

Used for producing various plastic plastic, paper plastic composite materials, it is an ideal bag making equipment for various medium sealed bags and three edge seals. Widely applicable for three sided sealing bag making of plastic composite film, aluminum-plastic composite film, paper plastic composite film, etc., and also suitable for the manufacturing of self-supporting bags, concave convex buckle bags, zipper bags and other shaped bags.

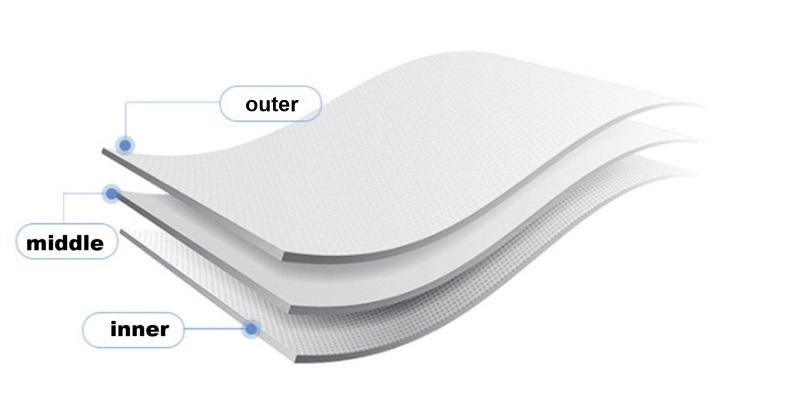

Outer layer: Enhance the mechanical strength, printability, and optical properties of the bag body.

Middle layer: Highlighting the main functions that conform to the structure, such as barrier properties, light blocking properties, fragrance retention, etc.

Inner layer: mainly used for sealing, followed by the compression resistance, drop resistance, sealing performance, etc. of the packaging material.

Common materials | Common materials |

BOPPM membrane/CPP membrane | Packaging bag for daily use of ordinary food boxes |

BOPP film/LDPE film | Packaging bag for daily use of ordinary food boxes |

BOPP film/VMCPP film | Moisture proof, powder proof, puffed food, etc |

PET polyester film/CPP film | Moisture proof, powder proof, puffed food, etc |

BOPP film/VMPET aluminum plated film/PE or CPP | Aluminum bags |

PET film/VMPET aluminum plated film/PE or CPP | Aluminum bags |

BOPP film/pure aluminum AL/LDPE | Aluminum bags |

PET film/pure aluminum AL/LDPE | Aluminum bags (the most commonly used aluminum foil bag composite method) |

BOPP film/VMPET aluminum plated film/LDPE or CPP | They are mainly used for products that need to maintain fragrance. |

PET/MPET film/LDPE or CPP | They are mainly used for products that need to maintain fragrance. |

Nylon film PA/LDPE PET/PA/LDPE | They are used for liquid packaging of food boxes that require refrigeration |

PET polyester film/PET/LDPE | Used for liquid packaging of food boxes that require refrigeration |

PET polyester film/nylon film PA/LDPE | Used for products that require high-temperature cooking |

Nylon film PA/cooking grade CPP film | Used for products that require high-temperature cooking |

PET polyester film/cooking grade CPP film | Used for liquid packaging of food boxes that require refrigeration |

1、 Technical parameters

Machine function with three side sealing and a zipper in the middle sealing

Main electrical configuration: traction two servo motors, equipped with Japanese Panasonic PLC, main drive is AC motor with Tai'an frequency converter, temperature control 16 channels, unwinding constant tension

Suitable for BOPP, COPP, PET, PVC and other plastic composite films, including multi-layer co extruded films, aluminum plated composite films, paper plastic composite films, and pure aluminum foil composite films

The maximum cycle time for bag making is 200 times/minute

The maximum discharge line speed is ≤ 35 meters per minute (depending on the material bag type)

Bag size and length: 400 millimeters. If the length exceeds this limit, double delivery will be used (maximum 6 times delivery)

Maximum width: 500 millimeters

The maximum size of the roll is Φ 850 × 1050 millimeters (diameter × width)

Positioning accuracy ≤± 0.5 millimeters

The number of heat sealing knives used for vertical sealing is 4 sets of up and down heating and up and down cooling

Horizontal sealing adopts 3 sets of upper and lower heating and 1 set of upper and lower cooling

Number of temperature electric heating blocks: 16 pieces

Temperature setting range: 0~300 ℃

The overall power of the machine is 46Kw (in actual use, the power is generally around 35Kw when first powered on, and around 15Kw when insulated)

External dimensions 11000 × 1900 × 1870 millimeters (length × width × height)

The net weight of the whole machine is about 4500 kilograms

Color cover, stainless steel

Control System Model: Industrial Control Computer Composite Film High Speed Bag Making Machine Control System

2、 Equipment configuration and related parameters

1. Material discharge device

a、 Structural form: Horizontal workstation (composed of magnetic powder brake, cylinder, swing roller, frequency converter, motor, traction roller sensor and control system)

b、 Feeding shaft, inflation shaft, and pneumatic locking device

2. Material release tension

a、 Control mechanism: A composite constant speed tension system composed of computer control, magnetic powder brake, frequency converter and AC motor, sensor and rotary encoder, and cylinder for swing roller

b、 Adjustment drive: PID adjustment PWM drive

c、 Detection method: Comprehensive detection of sensors and rotary encoders

3. Correction device

Structure: Screw adjustment K-frame vertical lifting and lowering

Drive: Solid state relay drives low-speed synchronous motor

Transmission: Coupling connection

Control form: Dual photoelectric sensor computer centralized control

Detection method: Reflective photoelectric sensor detection

Tracking accuracy: ≤ 0.5mm

Adjustment range: 150 mm

Photoelectric search range: adjustable within ± 5-50mm, range of limit switch Optoelectronic beyond range

The machine automatically stops and the computer prompts for abnormal correction

4. Opposite side

Structure: Adjustable rubber roller center bidirectional rotating adjustment structure

Form: Manual adjustment (adjusting handwheel)

5. Up and down against flowers

Structure: Single roller up and down adjustment

Form: Manual adjustment (adjusting handle)

6. Vertical sealing device

Structure: Composite Bridge Structure

Drive: The main motor drives the power rod

Transmission: Vertical motion of eccentric linkage

Quantity: 4 groups

Length: Hot knife 800mm, cold knife 400mm

7. Horizontal sealing device

Structure; Large beam cushion block hot pressing structure

Drive: The main motor drives the power rod

Transmission: Vertical movement of eccentric mechanism linkage

Quantity: 3 sets of hot knives, length: 540mm 1 set of cold knives, 1 set of zippers with a length of 540mm

8. Thin film traction

Structure: Pneumatic rubber roller compression friction type

Drive: Medium inertia digital AC servo system

Transmission: M-type synchronous pulley transmission, speed ratio 1:2.4

Control form: Computer centralized control

Detection method: Integrated control of photoelectric sensor combined with proximity switch

Third traction: AC motor power: 0.55KW Drive source Panasonic 0.75KW frequency converter

9. Intermediate tension

Structure: Pneumatic floating tension roller structure

Control form: Computer centralized control Dynamic motion compensation

Detection method: contactless proximity switch

Adjustment range of floating roller tension: 0~0.6Mpa air pressure, compensation range of intermediate traction motor: 1~10mm (computer set, automatic interpolation)

10. Main transmission device

Structure: crank rocker push-pull four-bar linkage structure

Drive: 3.7Kw frequency converter drives 3.7Kw three-phase asynchronous motor

Transmission: Main transmission motor with 1:17 reducer

Control form: Computer centralized control

Movement mode: The main motor drives the frame to move vertically up and down

11. Automatic positioning device

Method: (1) Computer automatic fixed length control method Accuracy: ≤ 0.5mm

(2) Reflective photoelectric sensor tracking and detection accuracy: ≤ 0.5mm

Optoelectronic search range: 0~10 mm (range size can be set by computer for automatic search)

Correction compensation range: ± 1~± 5 mm

Positioning correction method: The servo motor is controlled by the feedback signal from the computer

12. Temperature control device

Detection method: K-type thermocouple detection

Control method: Computer centralized control, solid-state relay driven PID regulation

Temperature setting range: 0~300 degrees

Temperature measurement point: middle section of electric heating block

13. Cutting knife

Structure: Upper cutter+adjustment device+fixed lower cutter

Form: Pneumatic top partition spring shear type

Transmission: Borrowing eccentric shaft power

Adjustment: Move horizontally, pull the handle to adjust the tangent angle

14. Border material collection machine

Structure: Horizontal reciprocating screw feeding structure

Drive: AC motor drive

Control: Sensor

15. Punching device

Structure: Bow shaped seat pneumatic punching die

Control form: Computer centralized control

Driver: Electronic switch driven solenoid valve (DC24V)

Punching seat: guide rail type support bow shaped seat with manual horizontal adjustment structure

Adjustment amount: ± 12mm

Cylinder: Pneumatic control

Mold: 1 set of circular holes

Quantity: 1 set of 'customizable'

16. Double delivery device

Structure: Pneumatic pad asynchronous insulation type

Control form: Computer centralized control

Driver: Electronic switch driven solenoid valve (DC24V DC)

Action mode: 3 sets of horizontal asynchronous actions

Multiple delivery times: from 2 to 6 times (can be set on the computer)

17. Automatic conveying device

Structure: L-shaped horizontal workstation

Drive: Solid state relay drive, gear reduction single-phase motor

Transmission: helical gear transmission

Conveying distance and quantity: freely set in the computer

Control form: Computer centralized control

3、 Supporting facilities (to be solved by users themselves)

Power supply: three-phase 380V ± 10% 50Hz air switch 150A

With neutral wire and ground wire (R.S.T.E)

Capacity: ≥ 42Kw

Gas source: 35 liters per minute (0.6Mpa)

Cooling water: 15 liters/minute