Pouch Making Machine - Three Side Sealing SBF 500

- Fully Automatic

- Three sides sealing

- Small Machine

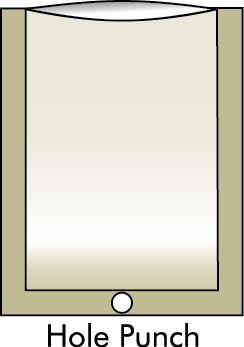

- Opitional:Hole punchers

- Can add rolling

- with triangle folding device

Description

Ruian Xuanhai Machine Manufacturer is a trusted manufacturer and exporter of high-performance pouch making machines, specializing in Three Side Seal Pouch Making Machine and Centre Seal Pouch Making Machine. Our advanced machines are engineered for high precision, durability, and efficiency, meeting the growing demands of the flexible packaging industry worldwide.

Our 3 Side Seal Pouch Making Machine is capable of producing pouches from PET/PE laminates, BOPP/PE laminates, aluminum foil laminates, and other flexible packaging materials. Designed for superior sealing strength and cutting accuracy, it ensures consistent quality and productivity.

One of our flagship models, the MJ-SBF 500 Series Three Side Seal Pouch Making Machine (also called sealing and shearing machine), is a fully automatic pouch making solution. It is designed for three-side sealing and precision cutting of laminated, aluminum foil, and printed composite bags. With high-speed operation and advanced sealing technology, this machine guarantees airtight, strong seals and high output performance.

Widely used in food packaging, pharmaceuticals, chemicals, and industrial applications, our pouch making machines are perfect for producing:

Stand-up pouches

Flat pouches

Vacuum-sealed pouches

As a leading pouch making machine manufacturer in China, Ruian Xuanhai Machine Manufacturer is committed to providing reliable, innovative, and cost-effective pouch making solutions for global markets.

Technical parameters

| Model | SBF 350 | SBF 500 | SBF 600 |

| Max bag width | 350mm | 500mm | 600mm |

| Max bag length | 480mm | 480mm | 680mm |

| Machine speed | 120pcs/min | 120pcs/min | 120pcs/min |

| Machine size | 4.5*1.05*1.8M | 4.5*1.2*1.8M | 4.5*1.3*1.8M |

| Machine weight | 1500KG | 1700KG | 1900KG |

Mechanical Part

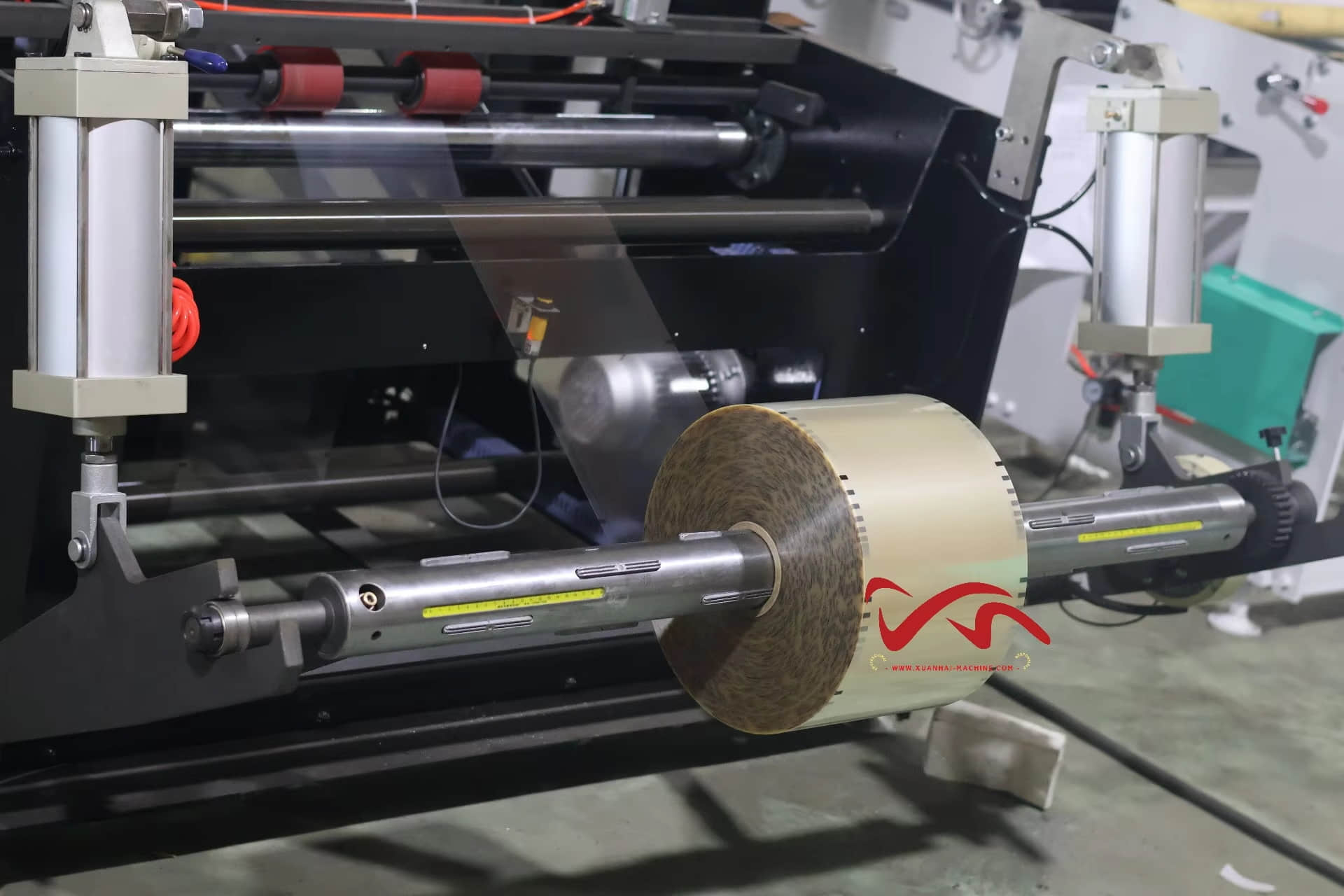

Unwinding Device: One unwinding edger, one standard unwinding rack, fixed with cone sleeve manual lock

Frame: 10mm steel plate structure for durability and stability

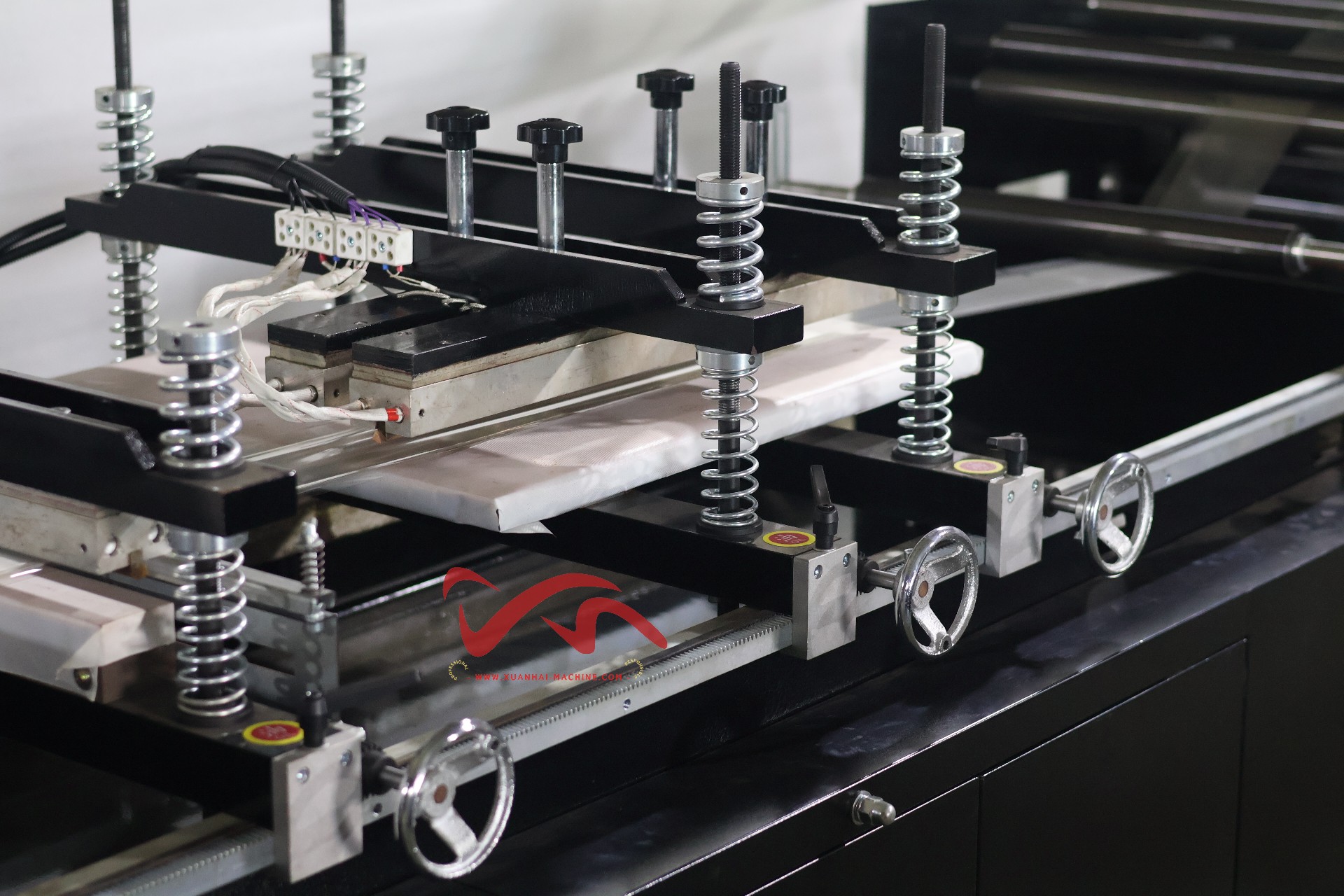

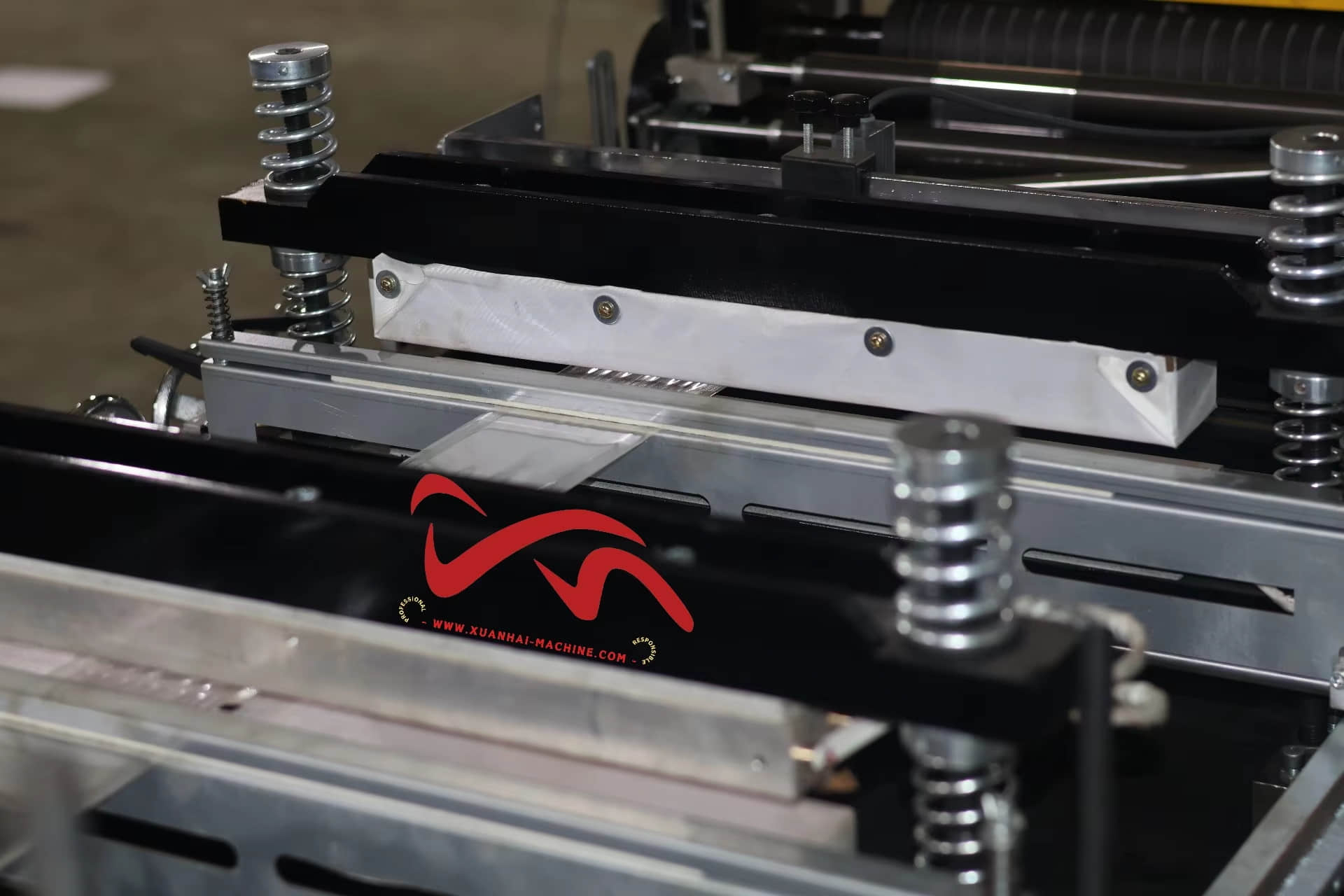

Cross-Cutting Knife Holder: High-strength casting structure

Cross-Cutting Knives: Standard domestic cutters, reliable and cost-effective

Drive Shaft: Rubber shaft with groove design for enhanced traction

Hot Knife System: Copper knives, including 2 pcs hot cross-cutting knives and 2 pcs hot vertical knives

Feeding Traction System: Rubber traction motor drives pulley shaft, equipped with two traction rubber rollers and two racks

Electrical Part

Main Drive: Variable frequency speed regulation (1.5KW motor), inverter from Hualan

Feeding System: One Delta servo motor for precise feeding

Traction System: Two pcs 0.75KW inverter motors (Shanghai) for stable traction control

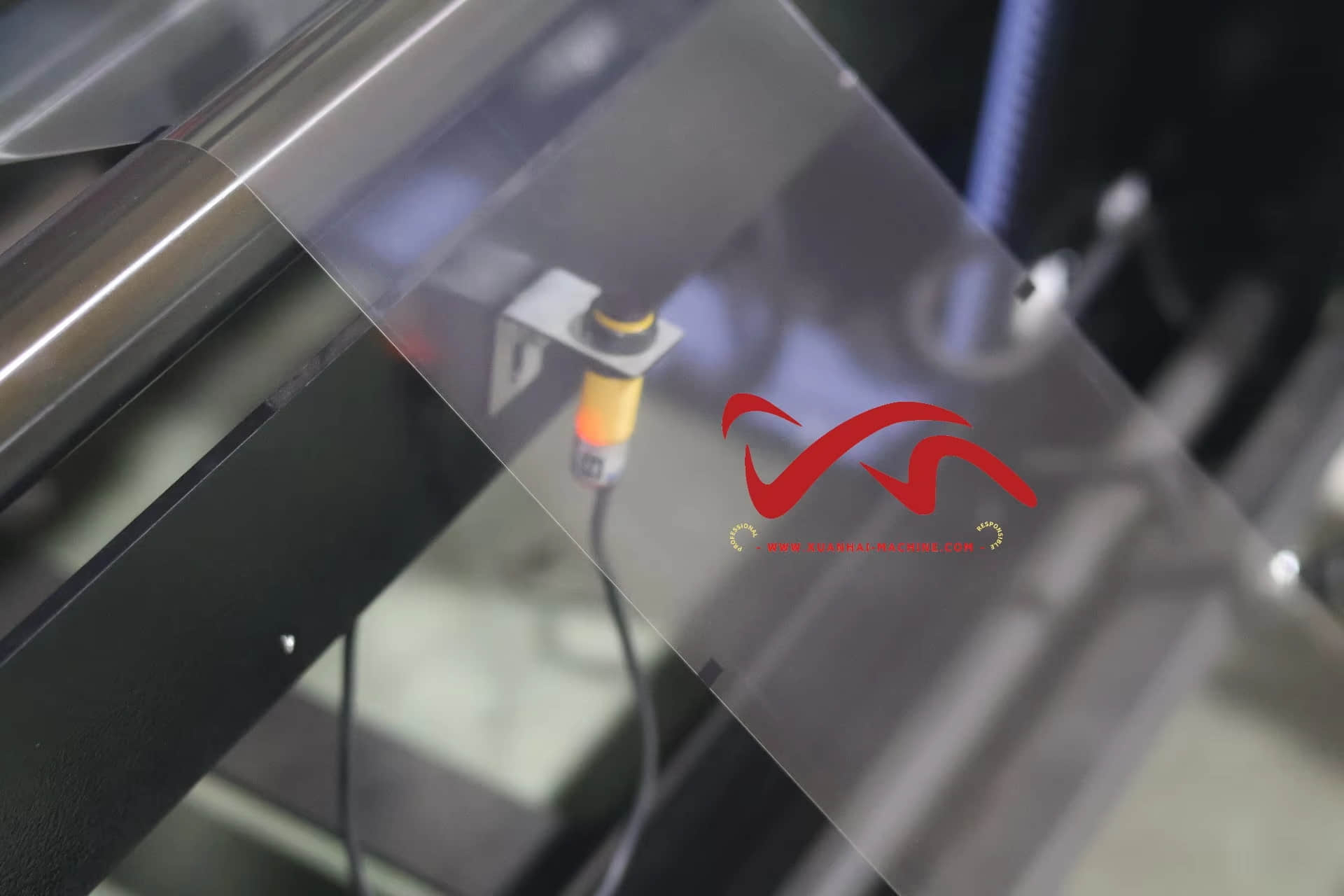

Photoelectric Tracking: High-accuracy positioning device (Zhejiang Julong)

Control Cabinet: Independent microcomputer control cabinet for stable performance

Touch Screen Control: Smart computer-based operation with user-friendly HMI

Main Motor: 1.5KW motor with reduction gear (Shanghai) for efficient power transmission

More machine pictures

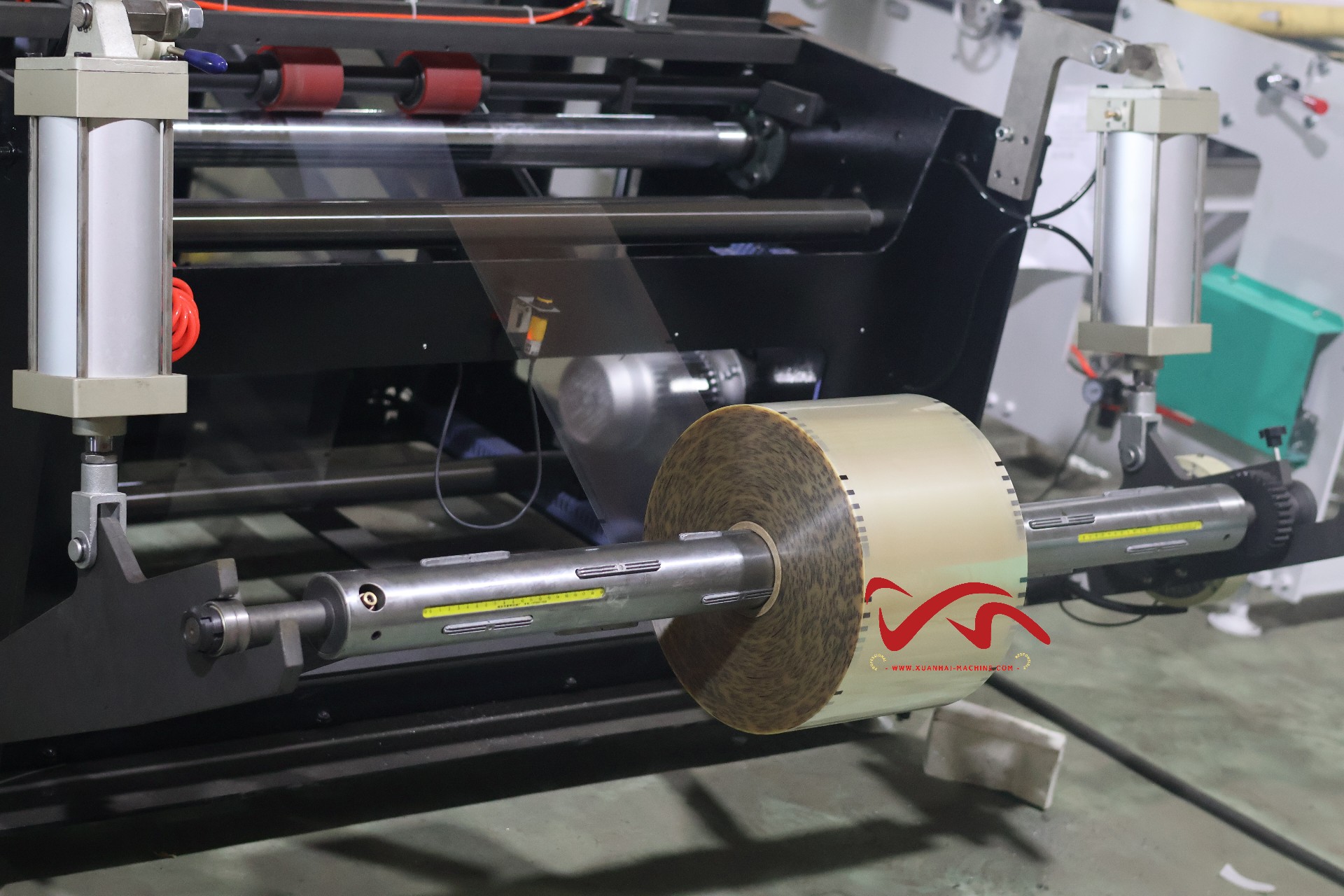

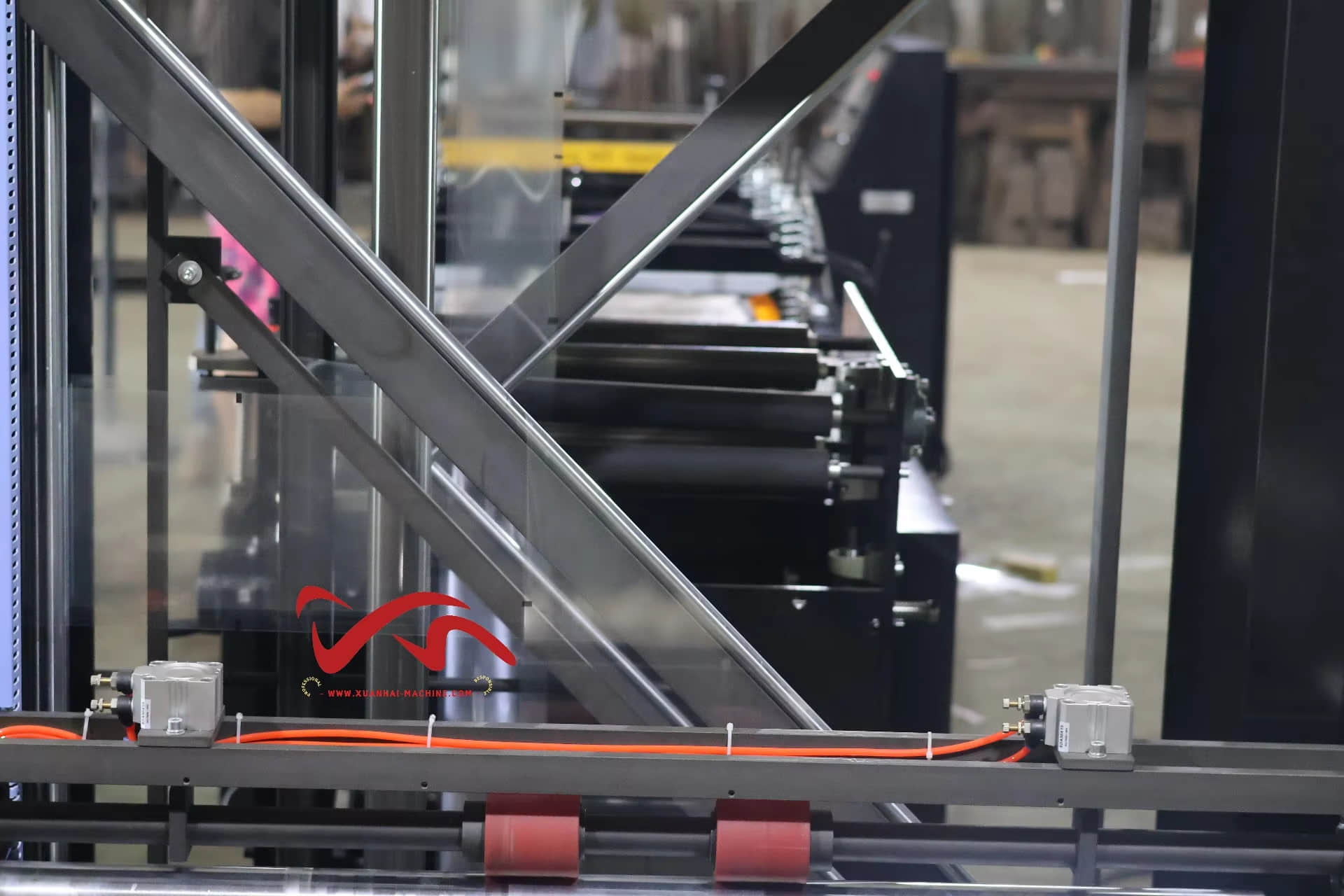

Unwinder roller

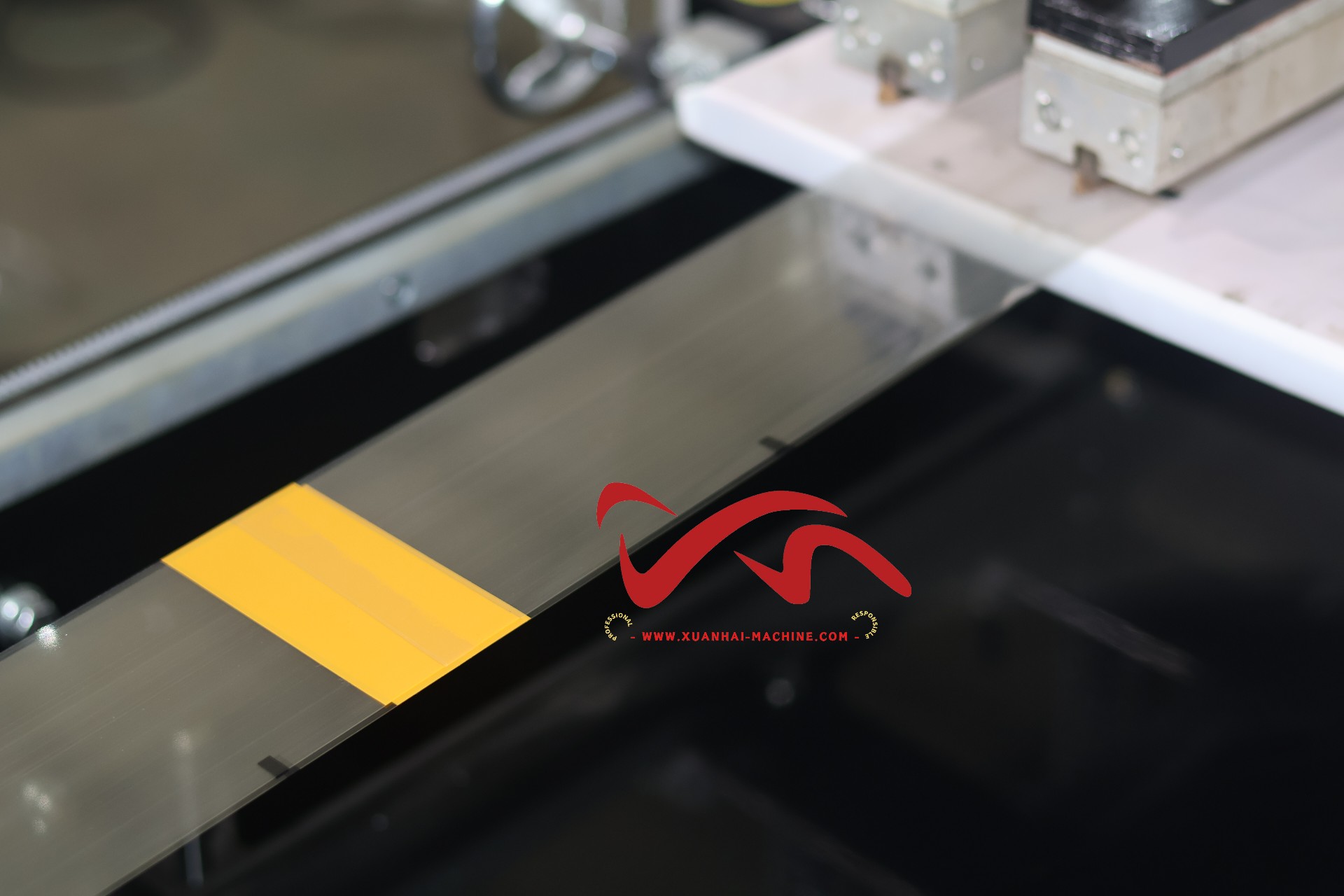

Web guide

Unwinder sensor

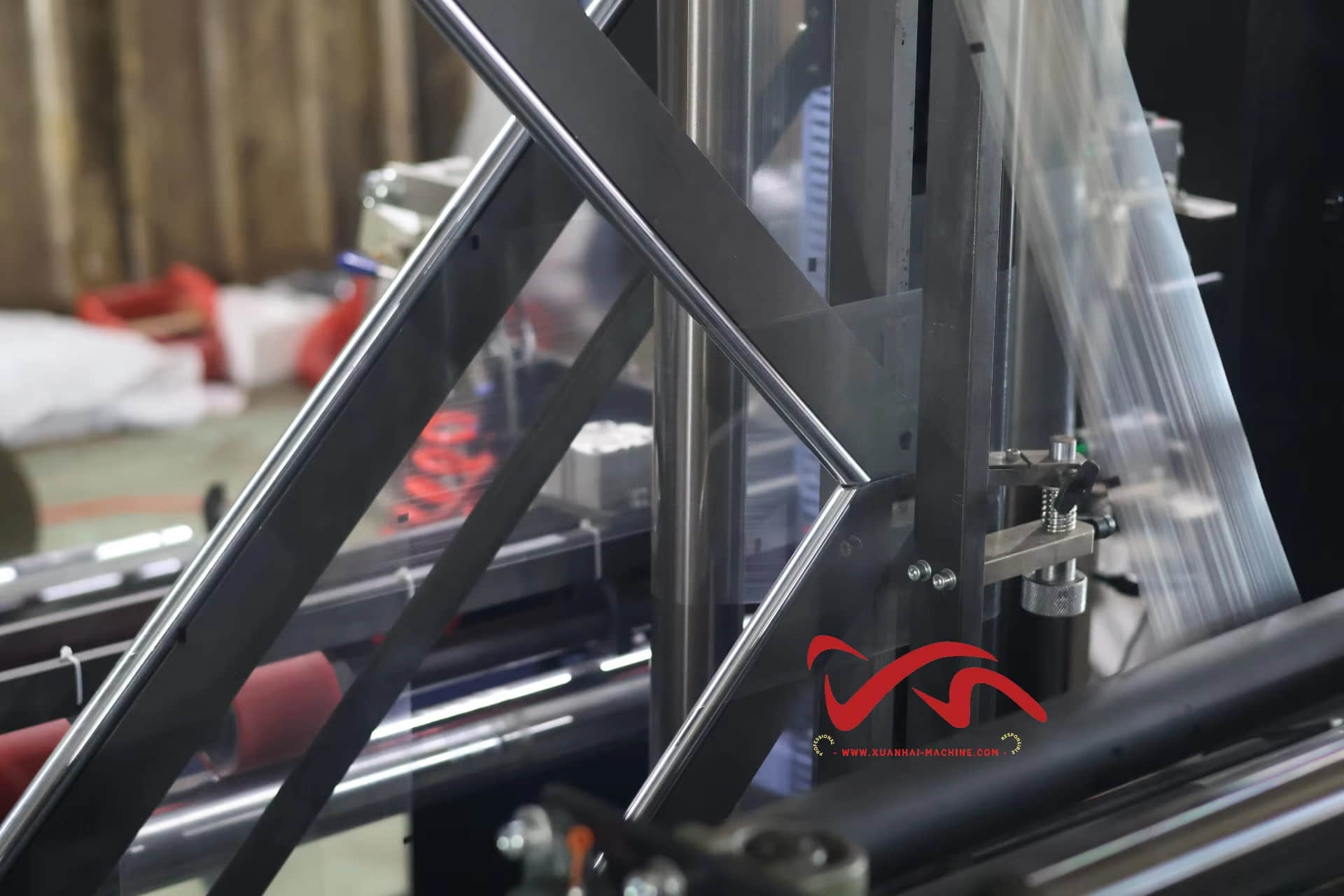

High quality roller

|  |

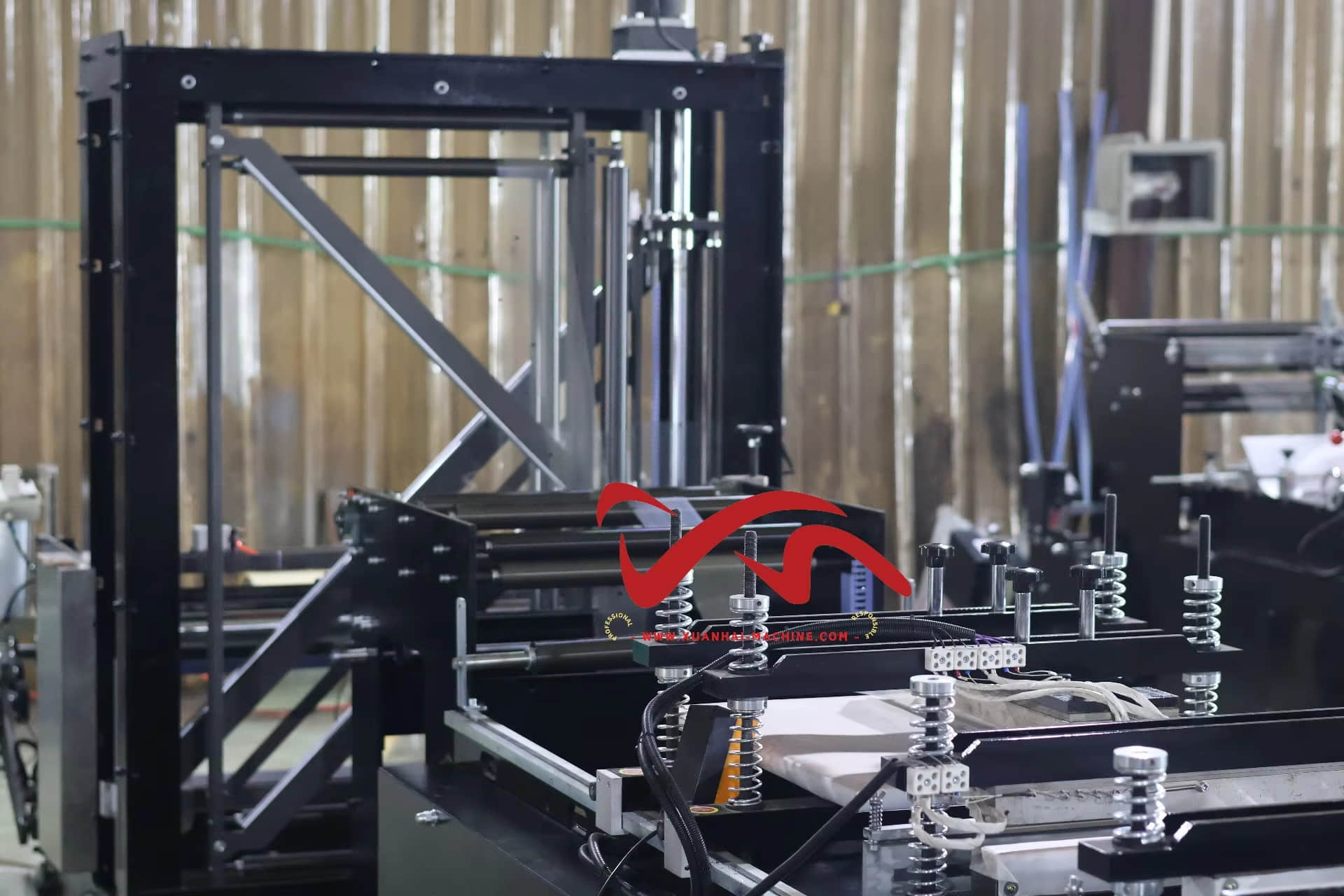

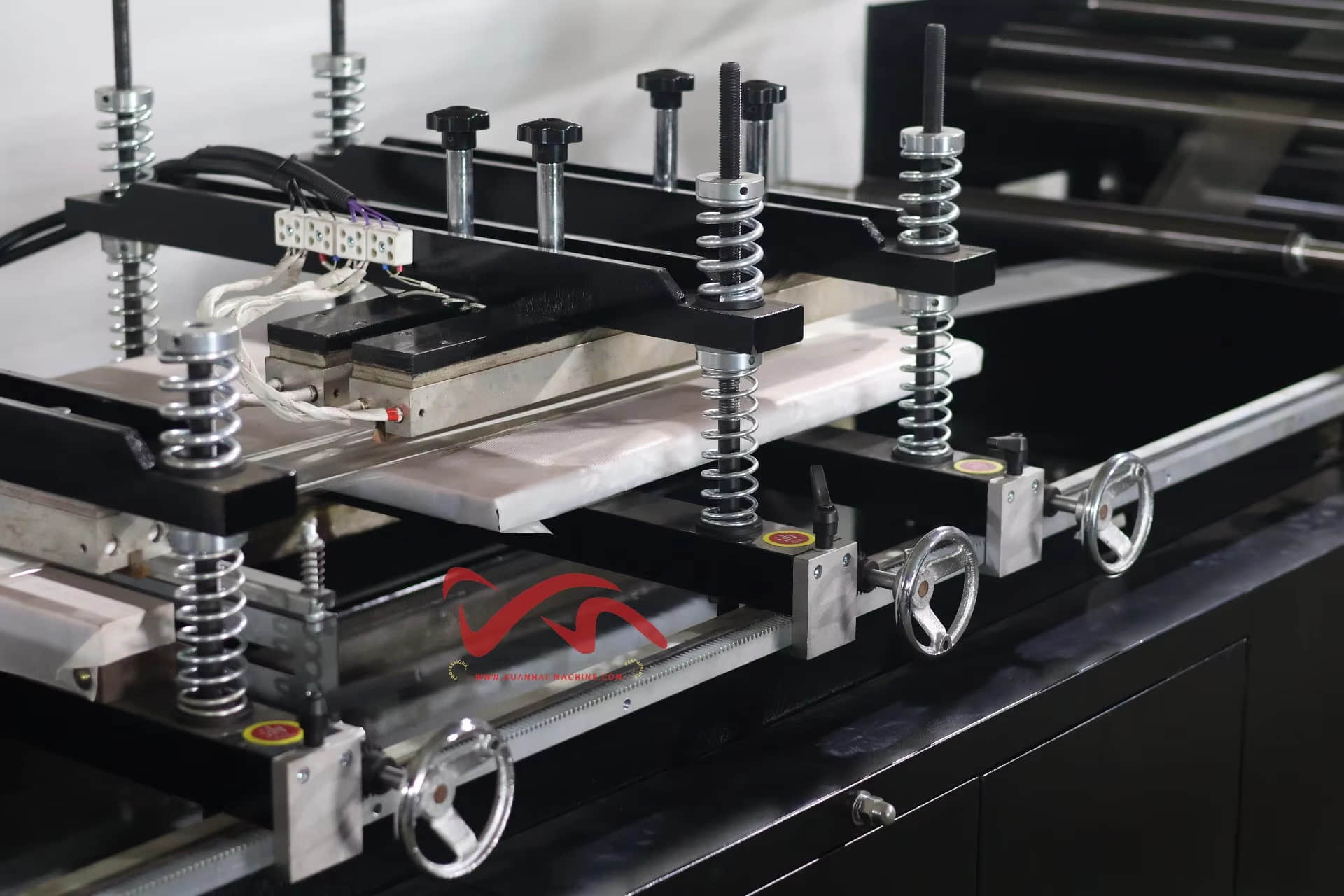

TRI ANGLE FOLDING AND CUTTING PART FOR THREE SIDE SEALING

Two sides sealing part

Bottom sealing part

PHOTOCELL FOR PRINTED BAG

FINAL BAG OUT/COMPUTER CONTROL

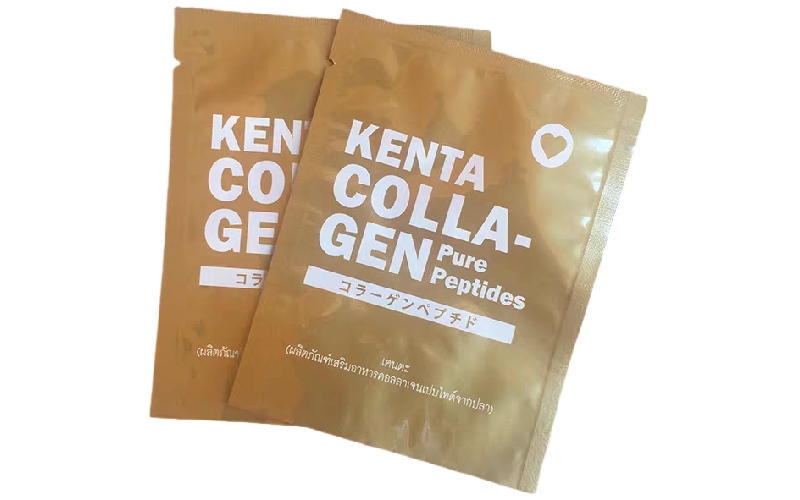

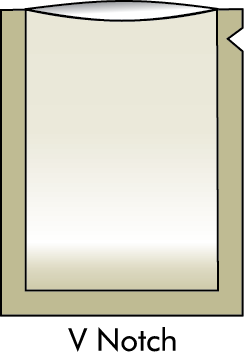

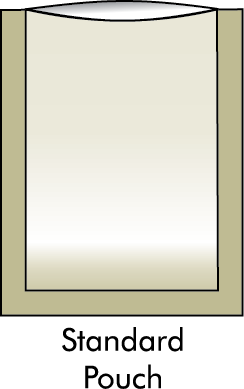

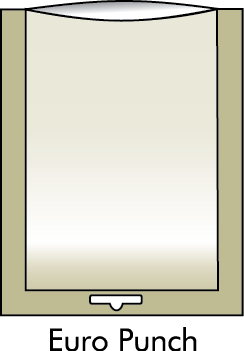

Bag Samples