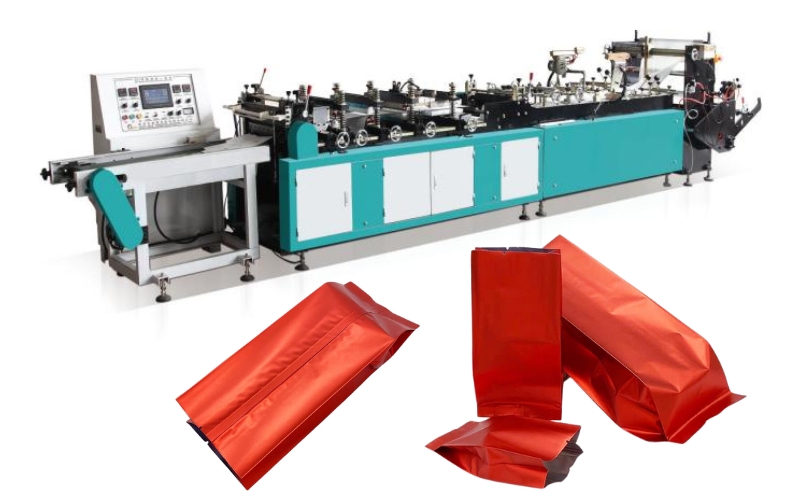

Boost Your Packaging Production with the MJ-350A Center Seal and Bottom Seal Bag Making Machine

- Nice Sealing

- Double servos

- Center seal and bottom seal in one step

- Fully Automatic

- Good price

- Fast shipping

Description

In today’s fast-paced packaging industry, efficiency, versatility, and reliability are critical. That’s where the MJ-350A Center Seal And Bottom Seal Bag Making Machine stands out. Designed to handle a wide range of materials including aluminum foil, BOPP, and PE coated paper, this machine offers unmatched performance in producing various center-seal and bottom-seal bags for multiple industrial applications.

🛍️ What Is the MJ-350A Center Seal and Bottom Seal Bag Making Machine?

The MJ-350A is a high-performance bag converting machine engineered for producing center-sealed and bottom-sealed pouches. Whether you’re working with laminated films, foil, or coated paper, this machine delivers precision and consistency across every bag.

🌍 Suitable Industries

The MJ-350A is ideal for manufacturers serving the following sectors:

Food Packaging: For coffee, tea, snacks, sugar, spices, and frozen food

Pharmaceuticals: Sterile packaging for medicines, powders, or liquids

Personal Care: Pouches for wet wipes, cosmetics, and hygiene products

Pet Food: Durable, sealed packaging for pet snacks and kibble

Agricultural: Seed and fertilizer bag applications

Chemical Products: Safe, leak-proof pouches for detergents or powders

🔧 Key Features of the MJ-350A

✅ Multi-Material Compatibility

Handles a variety of flexible materials including aluminum foil, BOPP, PE coated paper, and other heat-sealable laminates.✅ High-Speed, Stable Operation

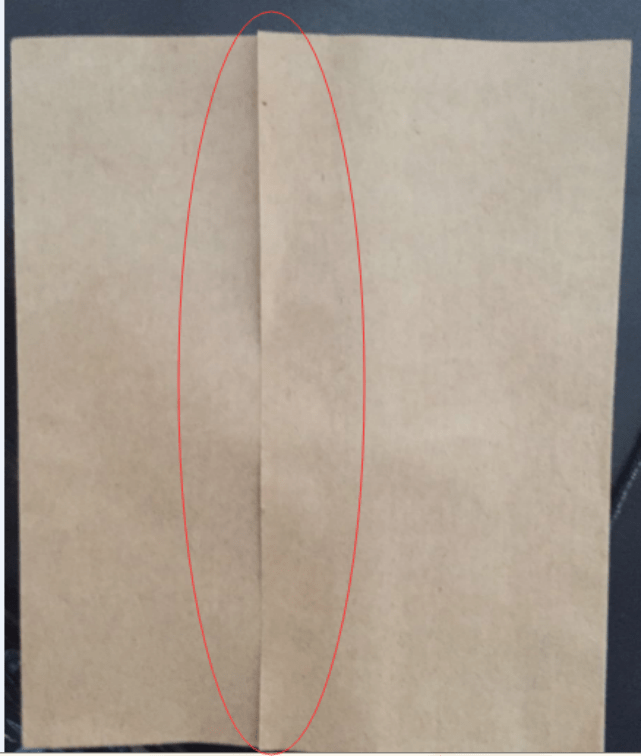

Designed for speed without compromising on quality—maintain fast production with minimal downtime.✅ Precise Temperature and Tension Control

Ensures strong, consistent seals even at high speeds, reducing waste and rework.✅ Center and Bottom Seal Capability

Offers versatile sealing configurations to match your product requirements.✅ Touchscreen Interface & PLC Control

Intuitive operation with smart controls for easy monitoring and adjustment.✅ Compact Design & Easy Maintenance

Space-saving structure with accessible components for quick changeovers and servicing.SPECIFICATION

MJ-350 Center Seal and Bottom Seal Bag Making Machine – Technical Specifications

Item Specification Model MJ-350A Bag Type Center seal and bottom seal bag Max. Material Width 700 mm Max. Bag Width 350 mm Max. Bag Length 400 mm (adjustable) Material Types Aluminum foil, BOPP, PET, CPP, PE coated paper, laminated films Film Thickness Range 0.04 mm Production Speed 30–120 pcs/min (depending on material and size) Sealing Type Center seal / bottom seal Temperature Control Intelligent PID controller with digital display Drive System Servo motor and inverter control Tension Control Automatic EPC (Edge Position Control) system Cutting System Rotary cutting with adjustable length setting Control System PLC control with HMI touchscreen Unwinding Diameter Max. 600 mm Power Supply 380V / 50Hz / 3 Phase (customizable) Total Power Approx. 10 kW Air Requirement 0.6 MPa (Dry and clean air) Machine Dimensions (L×W×H) 7000 × 1200 × 1500 mm Weight Approx. 1500 kg ✅ Optional Features:

Hole punching unit (Euro hole, round hole)

slitting knife

perforation knife

🏆 Why Choose Us as Your Machine Supplier?

As a professional packaging machinery manufacturer with over 15 years of experience, we bring more than just machinery—we deliver solutions that elevate your production:

✔️ Custom Solutions tailored to your packaging needs

✔️ 100% Repurchase Rate from satisfied clients across the globe

✔️ On-Site Factory Visits and live machine demonstrations

✔️ Fast Delivery and full technical support from our expert team

✔️ After-Sales Service with spare parts, training, and remote troubleshooting

📈 Take Your Packaging Business to the Next Level

If you’re looking for a center seal bag making machine that combines efficiency, flexibility, and quality, the MJ-350A is your best choice. It is specifically engineered to meet the demands of modern flexible packaging while reducing operational costs and increasing your bottom line.

📩 Contact Us Today

Ready to upgrade your bag making capabilities? Contact us now for a free consultation or factory tour. Let us help you find the best solution for your packaging line.

✅ machine also called:

MJ-350A center seal bag making machine, center seal and bottom seal pouch machine, aluminum foil bag making machine, BOPP bag machine, PE coated paper pouch machine, flexible packaging machinery, food packaging machine, high-speed bag making machine, packaging automation.