Complete Guide to Printing Quality Checking with Web Inspection Systems For Flexo Printing Machine

Description

📷 Web Video Inspection System for High-Speed Print Quality Monitoring

Advanced Real-Time Inspection for Flexo, Gravure, Offset, and Digital Printing Machines

Our web video inspection system is a high-precision solution engineered for real-time monitoring of print quality across various types of printing equipment — including flexographic, rotogravure, offset, label, rotary, and digital presses. Whether your operation handles narrow web labels, medium-width packaging, or wide-format film, this system provides continuous, high-resolution image feedback during production, ensuring early detection of defects and reducing waste.

🔍 What Does a Web Video Inspection System Do?

When printing presses operate at high speeds, it's virtually impossible for the naked eye to evaluate image quality in real time. The web inspection system solves this challenge by capturing ultra-fast moving print images and converting them into stabilized, high-definition visuals. These "frozen frames" can be magnified instantly to reveal even the smallest print flaws — such as color misregistration, smudging, or missing elements — long before they become costly.

💡 Key Features

Real-Time Image Capture: Converts high-speed print web into high-resolution still images for human inspection

Precision Defect Detection: Identifies micro-defects such as ink splashes, alignment errors, and color shifts

Wide Compatibility: Designed for integration with flexo, gravure, offset, label, and digital printing systems

Scalable for Web Sizes: Suitable for narrow (label), medium (film), and wide (packaging) web formats

Zoom & Pan Functionality: Allows operators to enlarge specific sections of the image without interrupting production

High-Speed Synchronization: Matches press speed to maintain frame accuracy during fast-running jobs

⚙️ Why Choose Our Web Inspection System?

Enhanced Print Quality: Detects print inconsistencies at the earliest stage to avoid rework

Operational Efficiency: Enables operators to make on-the-fly adjustments, reducing downtime

Visual Confirmation: Provides a real-time visual log of printing results for quality assurance

Versatile Integration: Installs easily on new or existing printing lines across various technologies

Cost Savings: Prevents large-scale material waste by catching defects before they accumulate

🧭 Ideal for:

Label Printing Quality Control

Flexible Packaging Defect Inspection

Rotogravure and Flexo Print Monitoring

Digital Press Output Verification

Offset and Wide Web Application Oversight

By integrating this smart camera-based inspection system into your printing process, you'll gain full control over print consistency, enhance customer satisfaction, and streamline your production workflow. It's the modern solution for printers who refuse to compromise on quality.

📷 Web Video Inspection System – High-Speed Camera Solution for Precision Print Monitoring

Next-Generation Camera Technology for Flexographic, Gravure, Offset & Digital Printing

The Observer Series Web Video Inspection System is equipped with ultra-high-resolution CMOS cameras engineered for real-time defect detection across a wide range of printing applications. With adaptable configurations for both narrow and wide web formats, the system is ideal for high-speed flexo, gravure, label, and digital printing operations seeking superior image clarity and automated quality assurance.

🔍 Camera System Specifications

10 Megapixel CMOS Sensor: Captures crystal-clear, high-definition images at industrial speed

Inspection Area:

Minimum: 13mm × 9.7mm

Maximum: 200mm × 150mm

Max Web Speed: Supports up to 1200 m/min continuous print speed

Power Supply: DC24V / 2.0A

Motorized Rail Length: Customizable from 300mm to 3000mm

Display: Standard 24” Full HD screen with 1280×720 or 1920×1080 resolution

🔧 Narrow Web Inspection System – Compact and Feature-Rich

Key Features

🔄 Motorized Linear Traverse Movement – Precision tracking across the web width

🎯 Real-Time RGB/CMYK Color Monitoring – Detects color drift and ink density variations

🔍 Image Freeze & Zoom – Lock and enlarge defect zones with up to 100X combined zoom

🌀 Image Rotation & Split-Screen – Compare live and frozen frames side-by-side

📏 Speed & Length Tracking – Displays real-time print speed and material usage

🎞️ Patrol Scanning Mode – Auto-loop scanning of web surface to flag hidden defects

🔧 Gamma Image Sharpening – Enhances fine details and sharpens image edges

Optimized User-Centered Design

The Observer narrow-web models are ergonomically engineered with dual-operation controls:

Remote & onboard camera keyboards

Compatible with most rotary printing presses

Optional dual-display setup for production-floor clarity

🚀 Wide Web Video Inspection System – Power Meets Simplicity

Designed for wide-format or high-positioned presses that require frequent camera movement, the Observer 4000M model integrates patented motor-drive technology and is trusted by flexo and gravure printers worldwide.

Specialized Functions for Wide Web Monitoring:

🖼️ 30X Optical Zoom – From wide overview to detailed analysis (with software up to 100X)

📸 10 Frames per Second Capture Rate – For ultra-fast image updates and live inspections

🧠 Auto Scan & CMYK Color Value Detection – Built-in tools for measuring real-time ink deviations

💡 Strobe Life Management – Prevents overuse and extends system lifespan

⚙️ Multi-Axis Image Rotation – Rotate visuals freely along X, Y, or XY axes

🪞 Split View Comparison – Instantly compare frozen and live images for defect validation

🏭 Universal Application for All Rotary Press Types

From drum-based to combination rotary presses, the Observer system adapts seamlessly to modern printing lines:

✅ Compatible with label, flexible packaging, film, foil, and paper substrates

✅ Supports inline or standalone integration

✅ Trusted for real-time defect detection, color monitoring, and print registration alignment

✅ Why Choose Observer Web Video Inspection?

Unmatched Visual Clarity even at 1200 m/min

Integrated CMYK Color Analytics for ink quality assurance

Customizable Traverse Options up to 3 meters

Operator-Friendly Controls with touchscreen UI and remote keyboards

Global Installations across hundreds of flexo and gravure lines

🧩 Typical Applications:

Flexographic and Rotogravure Print Quality Control

Label Printing Inspection Systems

Wide Web Film and Foil Monitoring

High-Speed Offset Defect Detection

CMYK Ink Deviation Diagnostics

By investing in the Observer Web Video Inspection System, you're equipping your press with an intelligent visual inspection engine that minimizes waste, ensures consistent print quality, and delivers actionable insights in real-time.

Specification:

OBSERVER | OV100 Motorized |

COSMOS SENSOR | 2M pixels |

OUT PUT RESOLOUTION | 1280x1024 pixels |

IMAGE VIEW | 90mmX67,5mm |

MAX OPTICAL ZOOM | 30X |

MAX. SHOOT SPEED | 10pics/sec |

MAX RUNING SPEED | 400m/sec |

MOTORIZED | + |

CAMERA MOVE SPEED | 52mm/sec |

VOLTAGE | 110V-240V, 50-60hz |

HUMIDTY | 20%-80% |

SIZE (LxWxH) | 110x238x290mm |

WEGHT CAMERA CONTROLLER | 9kg 3kg 6kg |

Printing Registration inspection | + |

Printing Quality inspection | + |

Dual cameras working for OVERSEER 100 MODEL

video web camera Print Image Inspection System for printing machine OVERSEER 200 series

The Overseer 200 series is the latest high-end, all-in-one camera printing quality checking web inspection system

Function:high pixel printing image observation system, the system adopts brand new hardware flat

Platform, supporting a newly customized graphical interface, can be work with touch screen and enhanced lighting Source, can bring smooth operation, powerful functions, and clarity to high-end web inspection system checking rquest customers

Clear and delicate image quality.

Conventional field of view, oversized field of view

Different customers have different requirements for vision, but they can see more paintings at once

Face is an unchanging pursuit. The Overseer 200 series, as well as the newly developed 200x120mm ultra large field of view.

Dual camera collaboration

A product that combines double-sided collaborative printing with front and back overprinting and die-cutting, and a minimalist design

Packaging is increasingly appearing in the market, which is crucial for observing printing images

Tong has put forward new requirements. Simultaneously specifying multiple locations for viewing (fixed-point cruising)

The requirement of quickly scanning the entire layout (full frame scan) is also testing the product. because

This Overseer series supports dual camera collaboration, and both cameras can

To complete fixed-point cruising and full frame scanning on one side, front and back of the printing material

Create a touchscreen graphical work interface and task-based menu for customer operations

Bringing great convenience.

20X optical lens

To achieve perfect image quality, any one of the camera, light source, or lens

We cannot have any shortcomings. We insist on using expensive optical lenses just to

Can bring customers clear and sharp effects that are different from digital amplification, and more

Good display of ink dots and colors, assisting customers in printing exquisite products.

Professional designed LED light sources and cameras

As customer printed materials become increasingly complex, ordinary lighting methods are no longer sufficient

Meet the needs. Therefore, we have hired a professional company to redesign the Overseer series

The light source and camera of the column, in terms of color restoration, clear image, and different materials

The best balance has been achieved in terms of requirements.

Customers can adjust the light source in the camera according to different materials, in order to

The machine and lens provide the most suitable lighting to capture the best results.

Fixed Point Cruise (PPS)

Users can easily manage tasks in the Overseer system

Fixed point cruise, which can be used to focus on observing trademarks, numbers

Decimal points, overprinting crosshairs, and other areas that are prone to printing errors. user

Just specify the position where the camera needs to stay on the rail, while also

You can request the system to take photos at each point to demonstrate the printing effect

, including the size of the image, duration of stay, etc.

Full format scan (AutoScan)

In order to improve printing efficiency, high-speed and wide format printing is becoming a trend in the printing industry

The trend is that the Overseer series can quickly adapt to the width of the printing format

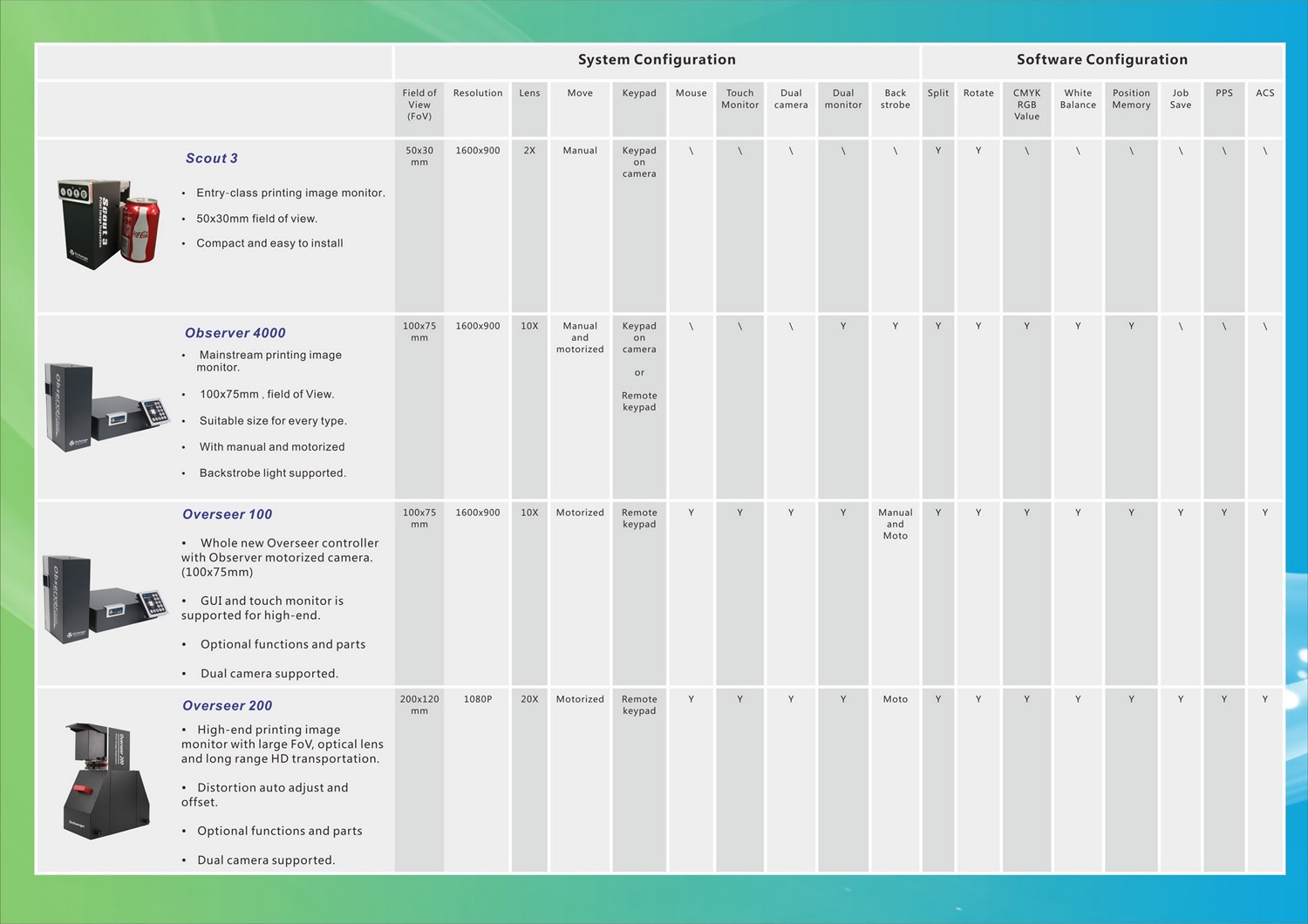

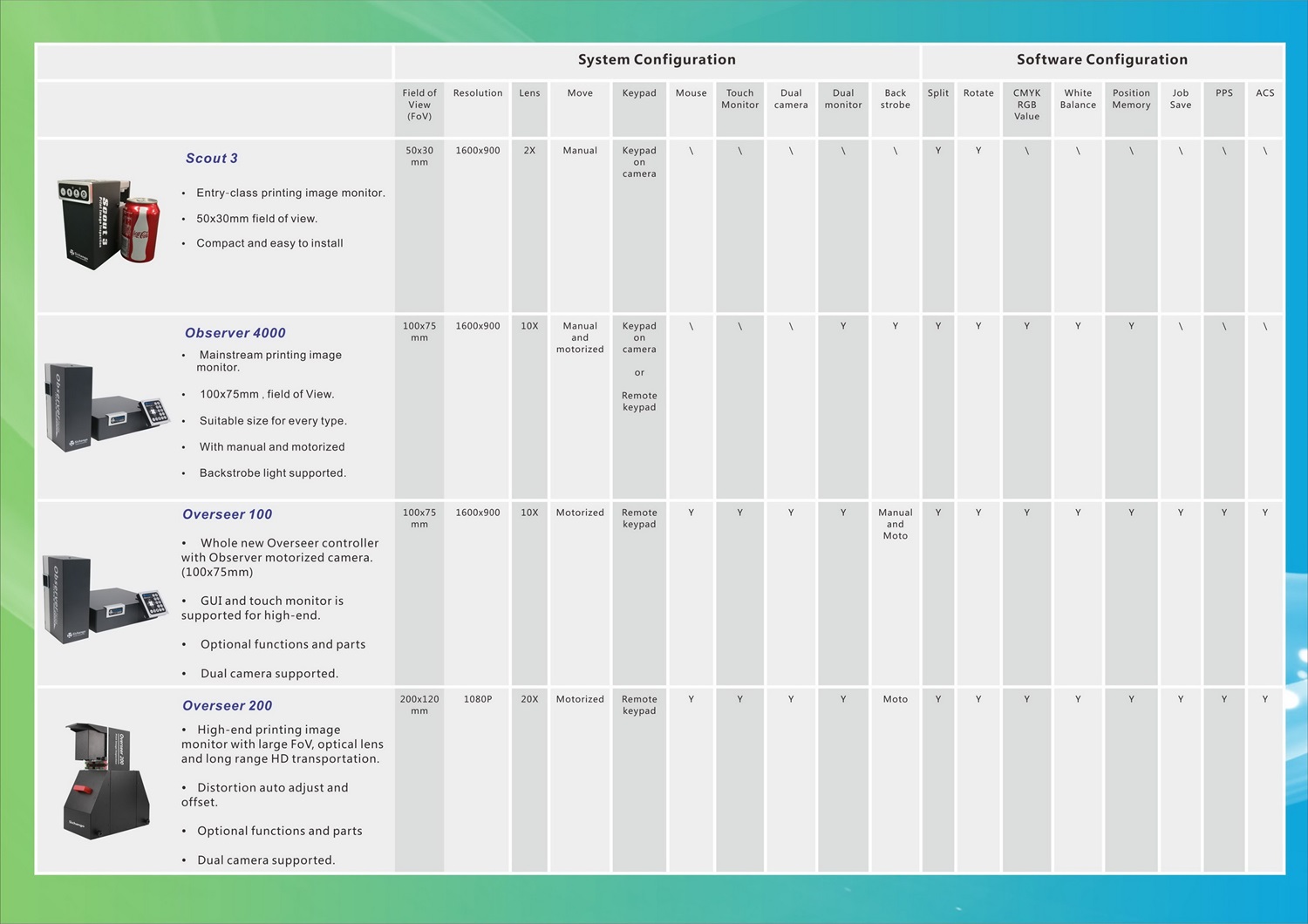

Here is our some models for your choose:

Can be installed in any place or your machine to meet different printing job requests.