Center Seal Pouch Making Machine with Laminated Film – Double Servo MJ-350A Xuanhai Manufacturer

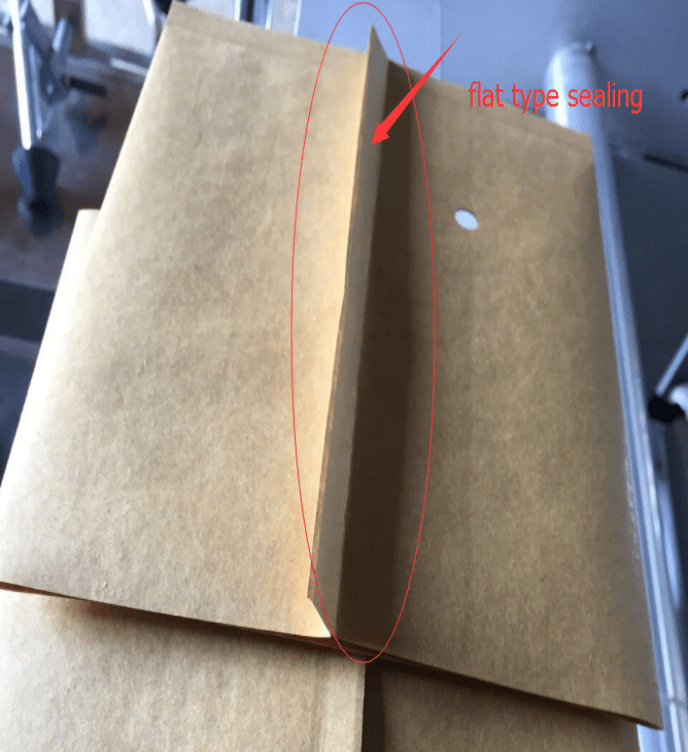

- Flat Sealing

- Small Machine

- Good price

- With Double servos

Description

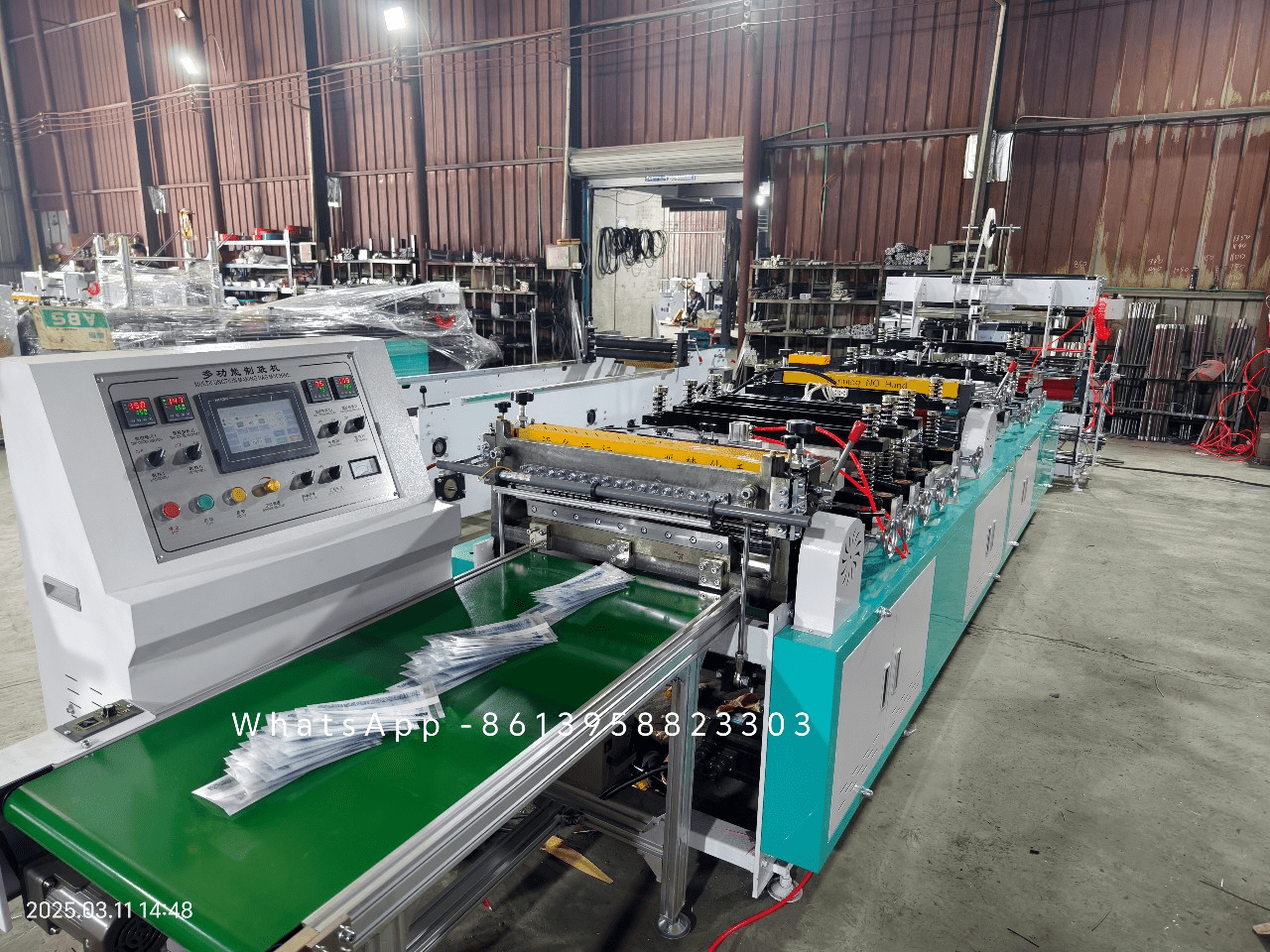

🏭 Center Seal Pouch Making Machine with Laminated Film – Double Servo Model MJ-350A

🧩 Product Description

The MJ-350A Center Seal Pouch Making Machine by Ruian Xuanhai Machine Manufacturer is a high-speed, fully automatic solution for producing center seal laminated film bags. It is designed to process plastic film, laminated foil, and coated paper, making it ideal for various flexible packaging applications.

This advanced center seal pouch making machine integrates double servo control, intelligent temperature regulation, and photoelectric tracking to ensure precision, efficiency, and reliability during high-speed pouch production.

Whether you are manufacturing coffee pouches, snack bags, medical-grade pouches, or pharmaceutical packaging, the MJ-350A laminated film pouch machine guarantees consistent sealing quality and superior cutting accuracy for professional packaging manufacturers.

🍭 Applications

Food packaging: coffee, snacks, candy, bakery bags

Medical & pharmaceutical packaging: sterilization pouches, tablet bags

Industrial flexible packaging: aluminum foil, coated paper, laminated film

Consumer products: toothbrush, cosmetic, and daily-use pouches

Suitable for PET/PE, BOPP/PE, paper-laminated, and multi-layer composite materials.

⚙️ Key Features

Double Servo Drive System

Dual servo motors provide precise film feeding, stable tension control, and synchronized sealing — ideal for laminated film applications.High-Speed & Stable Performance

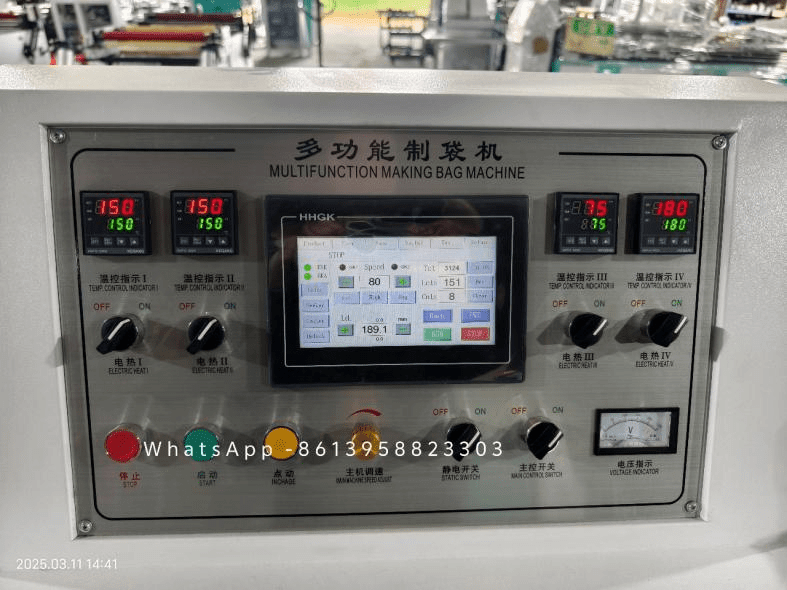

Capable of producing 80–120 bags per minute, the MJ-350A ensures continuous operation with minimal downtime.Microcomputer Control System

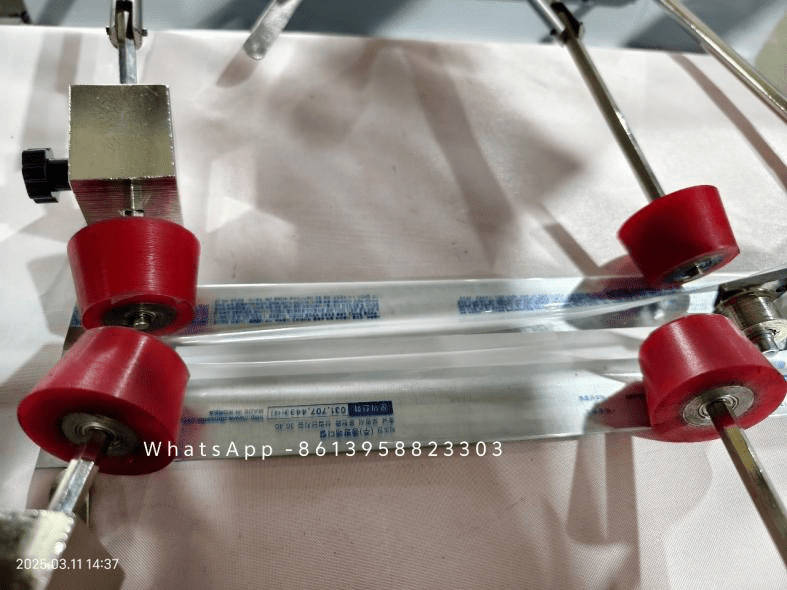

Equipped with an intelligent PLC system and HMI touchscreen, enabling accurate data input, easy operation, and seamless adjustment.Photoelectric Tracking System

Ensures accurate sealing and cutting positions with minimal waste, improving print-to-seal alignment precision.Intelligent Temperature Control

Stable heat sealing temperature prevents distortion and guarantees clean, airtight seals even at high speeds.Multi-Station Heat Sealing

Four sealing stations deliver consistent sealing strength across different laminated and composite materials.Customizable Functions

Supports euro hole, tear notch, zipper bag, and punching mold to meet customized packaging requirements.Durable Construction

Heavy-duty steel frame and premium components ensure long-term stability and vibration-free performance.Wide Industry Application

Used extensively in food, pharmaceutical, medical, chemical, and industrial flexible packaging sectors.

📊 Technical Specifications – MJ-350A Center Seal Pouch Making Machine

| Item | Specification |

|---|---|

| Model | MJ-350A |

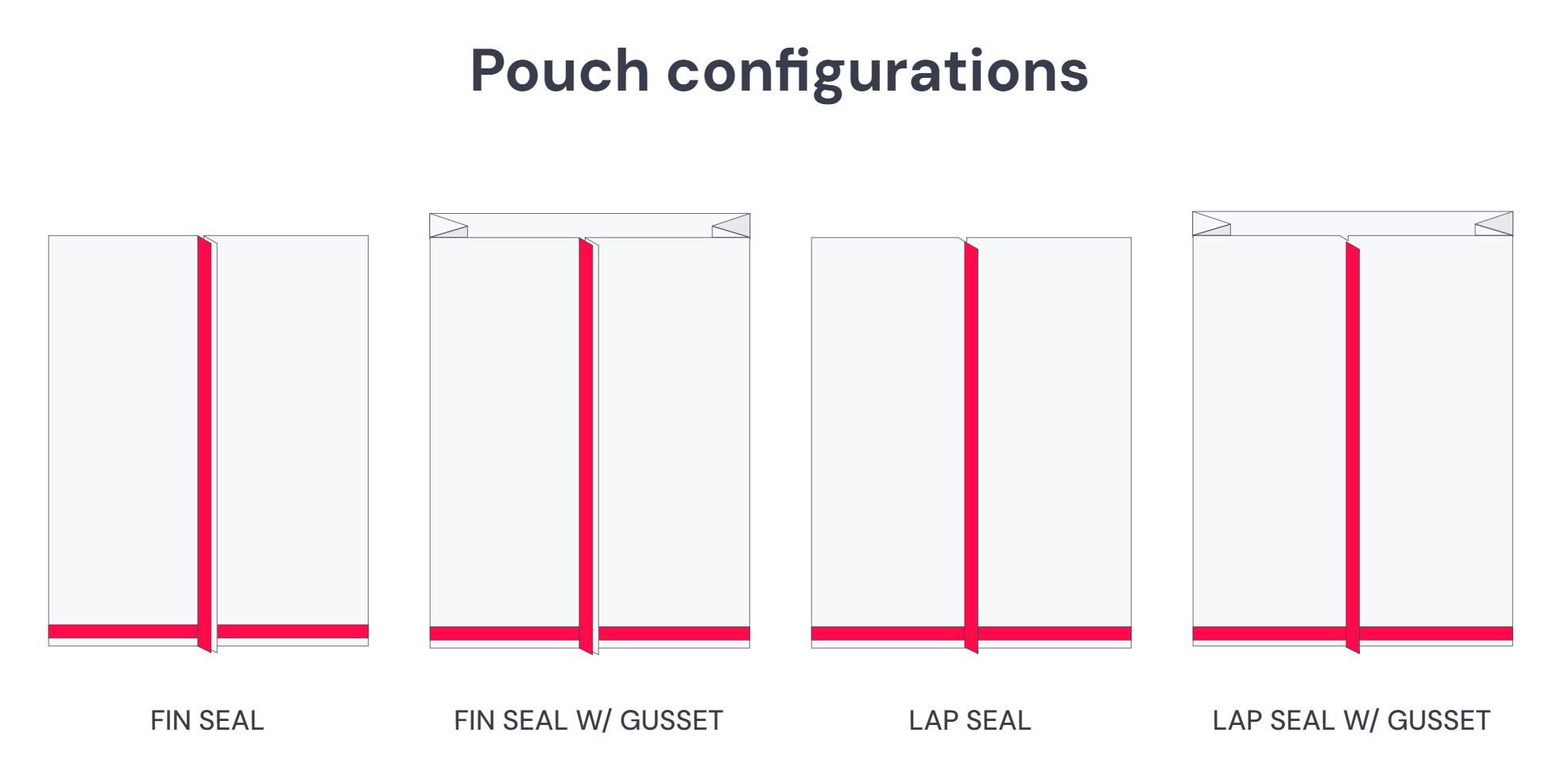

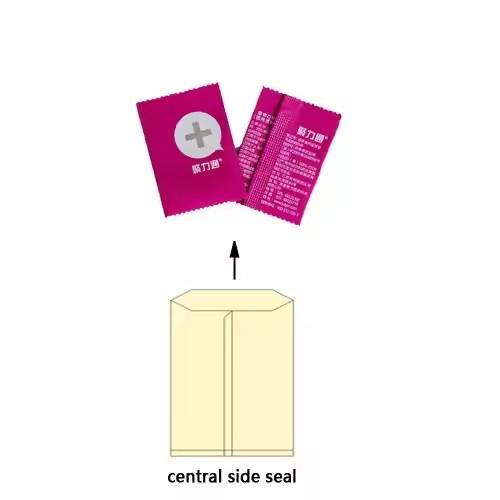

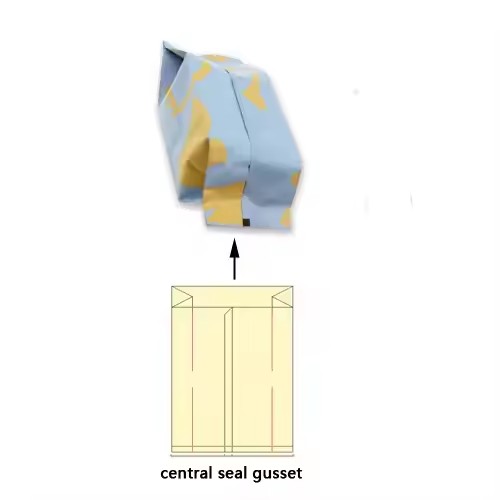

| Bag Type | Center Seal / Middle Seal / Pillow Pouch |

| Applicable Materials | PET/PE, BOPP/PE, NY/PE, Aluminum Foil, Paper Laminates |

| Film Thickness | 0.04–0.15 mm |

| Max. Bag Width | 350 mm |

| Bag Length Range | 50–300 mm |

| Production Speed | 80–120 pcs/min |

| Sealing Type | Center Seal + Optional Bottom Seal |

| Temperature Control | Intelligent PID Control |

| Tracking System | Photoelectric Sensor |

| Drive System | Double Servo Motor Drive |

| Power Supply | 380V / 50Hz / 3 Phase |

| Total Power | 7.5 kW |

| Machine Dimensions | 4200 × 1300 × 1800 mm |

| Net Weight | 1500 kg |

| Manufacturer | Ruian Xuanhai Machine Manufacturer |

| Country of Origin | China |

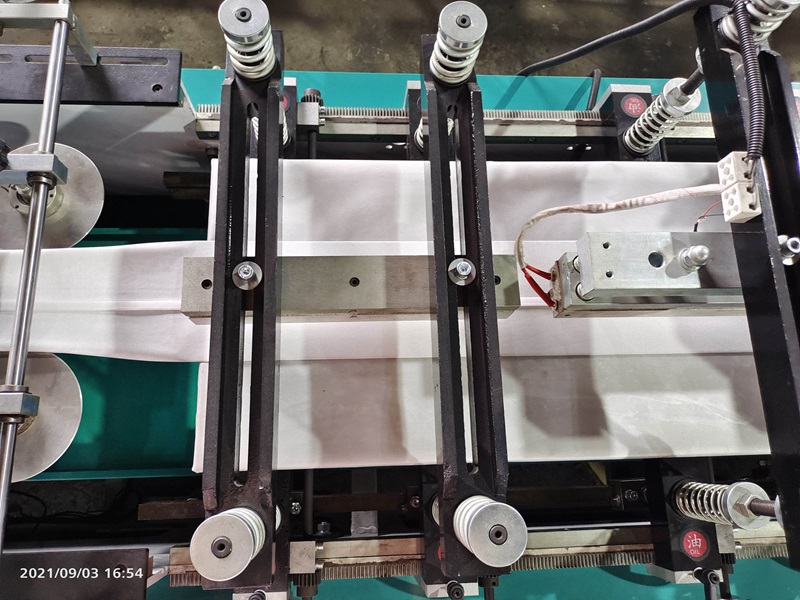

Machine Configuration

| Mechanical part | Electrical part |

1. Unwinding device: the unwinding device adopts magnetic powder and air shaft | 1. Unwinding magnetic powder 2.5KG (china brand) |

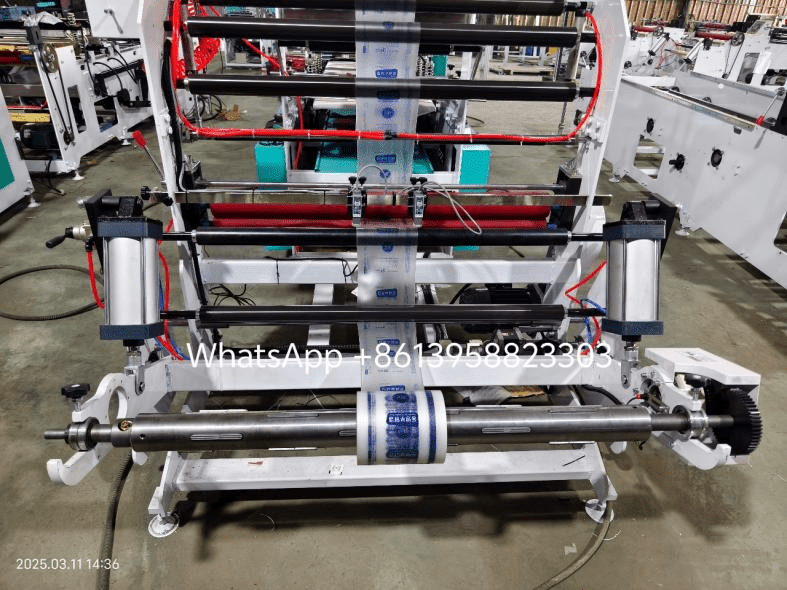

2. Frame: adopt steel plate structure | 2. Double servo motor control 2KW 2sets |

3. Cross-cutting tool holder: adopts casting structure | 3. Double photoelectric tracking and positioning device for edge correction machine (Zhejiang Julong) |

4. Cross-cutting knife: using domestic ordinary cutting knife | 4. Independent microcomputer control cabinet: automatic counting, automatic alarm when the number is reached. Automatic shutdown function for lack of material |

5. Drive shaft: rubber shaft slotted | 5. Traction adopts variable frequency motor speed regulation (Shanghai) |

6. Hot knife: The bottom seal adopts aluminum structure (2 two horizontal ironing, 1 cooling.) The middle sealing hot knife adopts a longitudinal ironing knife, and 1 longitudinal cooling and flat pressing. | 6. Computer touch screen control (PLC) |

7. Feeding traction mode: motor drives belt pulley to drive traction rubber shaft | 7. Main engine adopts 2.2KW motor (Shanghai) |

8.Max material width 700mm max bag width 330mm | 8. working speed 120 bags/min |

| 9. Whole machine weight 1500kg | |

10. Dimensions: length 6.7 meters width 1.3 meters height 1.5 meters |

More machine pictures

|

|

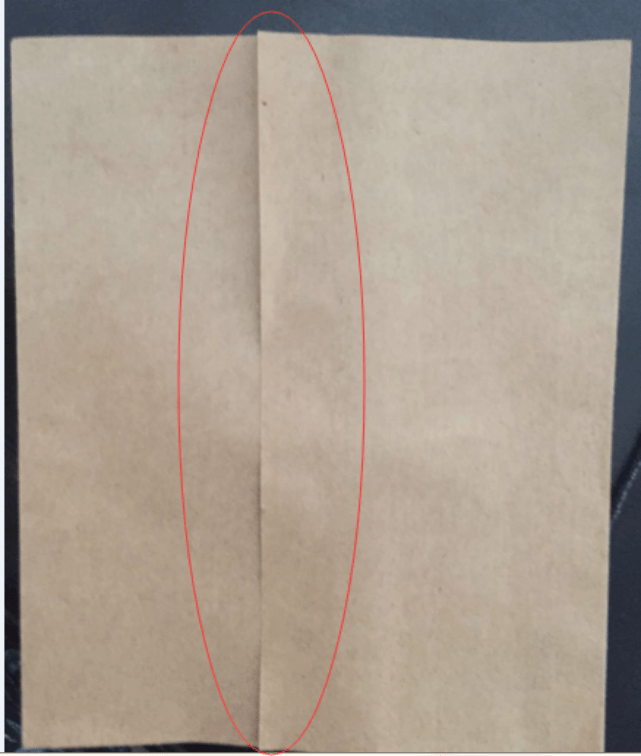

Unwinder with cylinder loading,with double photocell | Central folding |

Bag forming | |

|

|

|

|

Computer control to set speed,batch | Photocell for tracking printed bag |

|

|

Bag comes out on conveyor belt | |

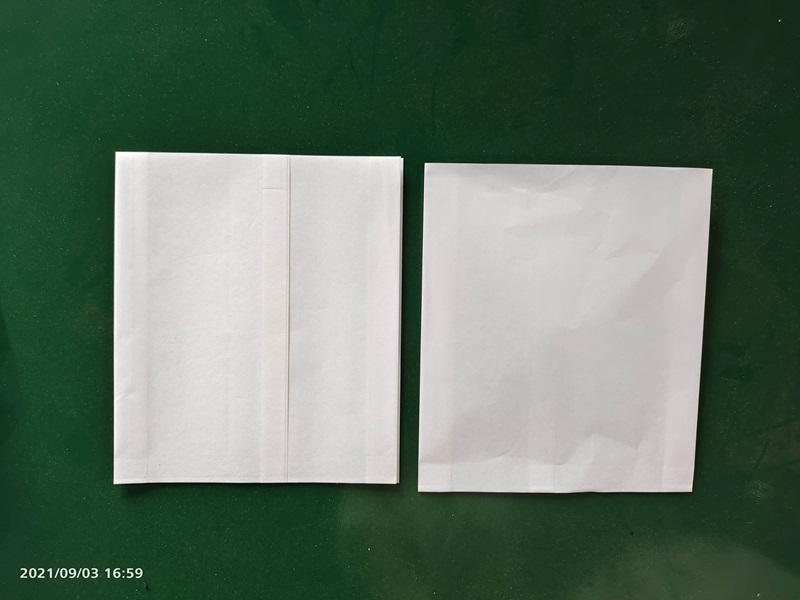

Bag Samples

|  |

|

|

🌍 Why Choose Ruian Xuanhai Machine Manufacturer

With over 35 years of professional experience, Ruian Xuanhai Machine Manufacturer is a trusted supplier of automatic pouch making machines in China.

Our product portfolio includes Three Side Seal Pouch Making Machine, Center Seal Pouch Making Machine, and Stand-Up Zipper Pouch Making Machine, serving customers across the food, medical, and industrial film industries worldwide.

Each Xuanhai machine is engineered for precision performance, intelligent automation, and energy-efficient production, helping clients achieve higher speed, stronger sealing accuracy, and reduced operation costs.

Others machine you may interested