Label Core Guide: How to Choose the Right Size and Avoid Waste with Unsuitable Core Labels

What is a Label Roll Core and Why Does It Matter?

Labels are the main body of the print, When purchasing label printer supplies, most people focus on label size, adhesive type, or surface material, but often overlook a crucial parameter: the label paper roll core. Using an incompatible label roll can not only cause paper jams but can even damage the printer.

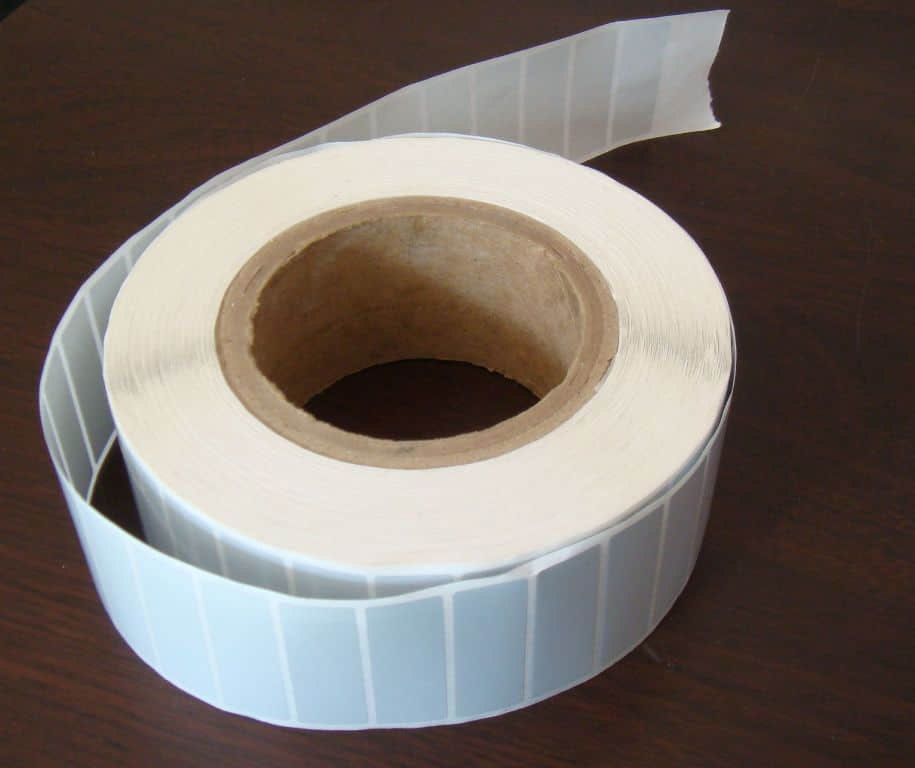

The label roll core—the hollow paper tube in the center of the label roll that supports the label material—may seem insignificant, but it is actually crucial to successful printing.

The roll core is used to wrap the label paper around it and secure the label roll to the barcode printer's label holder. The roll core size is determined by the inner diameter of the paper tube, which is also the diameter of the central hole.

Common label roll inner diameters include 1 inch, 1.5 inches, and 3 inches. There are no strict specifications for the inner diameter of the roll core. Different sizes determine whether the label roll can be inserted smoothly into the printer, and the core size is the most important factor for fitting into the label holder.

Common label roll core sizes include:

- 1-inch (25.4 mm) for office/small business desktop printers

- 1.5-inch (38.1 mm) for compact industrial models

- 3-inch (76.2 mm) for warehouse/industrial printers

According to industry research, using an inappropriate roll core causes jams in 73% of label printers.

Important: The outer diameter (OD) must also fit within your printer's hopper.

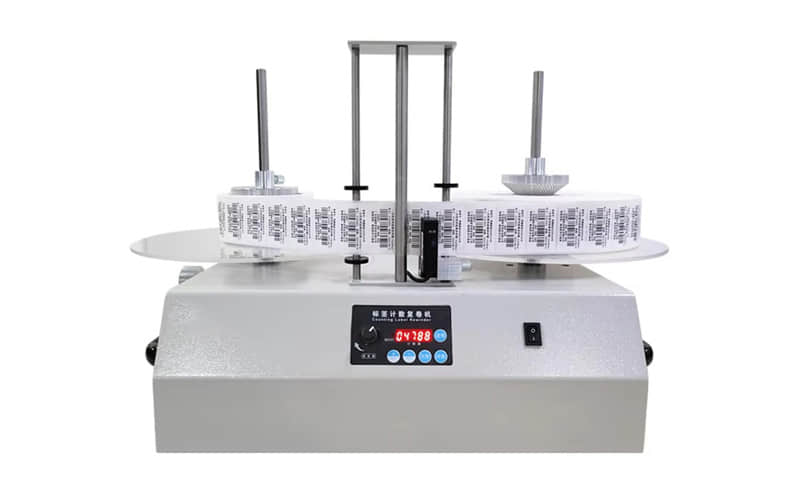

Automatic label rewinding machine rewind label rolls with oversized or undersized cores to compatible sizes, ensuring your label rolls are used as intended and avoiding waste!

The High Cost of Using the Wrong Label Roll Core

Choosing the wrong label roll core can lead to:

Printer damage (58% of repair calls are related to spindle wear caused by mismatched roll cores)

Label waste (up to 20% material loss due to misfeeding)

Downtime (average 3.7 hours per week) (Troubleshooting roll-related issues)

Real-world example: A logistics company lost $8,500 monthly from misprinted shipping labels before implementing roll core standardization.

How an Automatic Label Rewinding Machine Solves Core Problems

Taking our automatic label rewinding machine as an example, different sizes of shafts (1-6 inch shafts are optional) can be used to rewind the label core. At the same time, the machine can be equipped with 20 different functions according to customer needs and industry characteristics to meet the needs of rewinding, rewinding, splitting, metering, counting, and inspection of various types of rolls. It can also be used in conjunction with the installation of inkjet printers, visual inspection machines, etc.

Machine Features

1. Replaceable Take-Up and Take-Down Shafts: Place the original label roll onto the take-up shaft on the reel, then select the take-up shaft with the correct core size and secure it to the reel. The machine features an automatically inflatable shaft and interchangeable base for fast loading and unloading. Shafts of varying sizes (available in sizes from 0.4" to 6") are easily replaceable, leak-proof, and durable.

2. Tension Control: Electromagnetic braking facilitates tension control during label rewinding. The electromagnetic tension is digitally adjustable, enabling convenient operation and data management.

3. Optional Photoelectric Meter/Counting Sensor: Combined with a frequency converter or multi-speed controller, the machine can be automatically stopped with a slow speed control when the number of meters or pieces has been reached, providing even more accurate meter/counting.

4. The take-up shaft features an optional forward/reverse rotation function. This machine features a unique design, extremely low power consumption (approximately 0.1-0.2 kWh per hour), a compact footprint, and simple operation.

5. The speed control is digitally adjustable, enabling convenient operation and data management.

5-Step Guide to Choosing the Perfect Label Roll Core

Label roll core size is crucial for printing stability and operational efficiency. Choosing the wrong size not only wastes label material but can also damage equipment and disrupt workflow. Choosing the appropriate inner and outer diameters to mitigate risk at the source is fundamental knowledge every label printing user should master.

1. Check Printer Manual

- Confirm supported inner diameter (ID)

Most label printers have an internal paper roll that secures the label roll core . If the inner diameter of the label core does not match the roll size, the label roll will not fit properly, potentially causing jams, misalignment, or feed problems.

- Note maximum outer diameter (OD)

This is the diameter of the entire label roll (including the label paper and core) from edge to edge. The OD determines whether the label roll will fit into the printer's paper compartment. Generally speaking, the outer diameter of a label roll is typically between 4 and 8 inches, depending on the length and thickness of the roll.

2. Assess Usage Volume

Most desktop thermal printers are designed for a 25 mm (or 1 inch) roll core, while larger industrial printers are typically designed for a 76 mm (or 3 inch) roll core. Many other printers and labeling applications use sizes between these two sizes.

3. Verify adapter options

- Some printers can accept multiple roll sizes using adapters.

4. Consider material thickness

- Thicker labels require larger cores to prevent stretching.

5. Plan for future needs

- An automatic rewinder provides flexibility as needs change, with options for 1-6 inch roll cores.

When to Invest in a automatic Label Rewinding Machine to Solution

Consider an automatic label rewinding machine if your business:

- Uses multiple printer models with varying roll requirements

- Frequently receives labels from suppliers with non-standard roll cores

- Wants to reduce the complexity of your label inventory

- Frequently experiences printing errors due to roll core mismatches

Call for action:

Ready to solve your label roll challenges? Contact us today and we'll tailor label rewinding machine to your specific needs.