Automatic Web Inspection System for Printing Quality of Flexographic Machine With Alarm And Report

In the practice of conducting in-depth research on the printing production process and its pre - and post process characteristics, the company has formed

It has become a complete solution for online printing quality inspection and printing quality defect management, providing users with production process control.Automatic Web Inspection System for Printing is quite important to provide perfect printing product to end user.

A production quality control plan that combines defect detection, elimination, and printing defect management.

Production process control refers to real-time detection of print quality, real-time production quality process control - real-time discovery of quality

Once a defect is detected, the equipment will automatically shut down.

Defect detection and elimination refers to the removal of defective products to prevent unqualified products from leaving the factory.

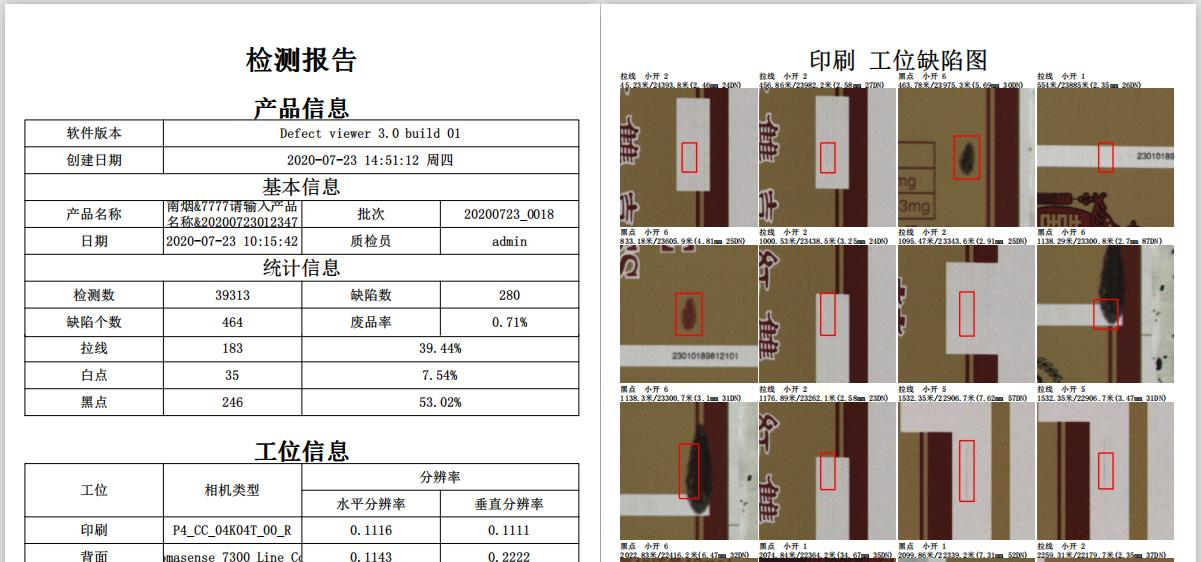

Printing defect management refers to the printing quality inspection system that can provide detailed and comprehensive quality defect records and analysis reports,

According to the defect classification statistical report, it can assist operators in discovering key control issues in production and conducting post quality control

Quantitative analysis, tracking, and defect data statistics to assist in quality control and production management.

The online printing quality inspection system is a distributed machine vision inspection system independently developed by Huazhi Weishi, which provides

A solution for process control and quality assurance, suitable for various roll printing equipment and printing materials. This detection system is designed for production

Real time detection of printing quality, once printing defects are detected, the detection system will provide real-time sound and light alarms to remind production personnel to print

Adjust the equipment to avoid a large amount of waste, in order to achieve production process control.

The following are photos of the application of our online detection system on site:

2. Design of testing plan for Automatic Web Inspection System for Printing

By analyzing information such as equipment production processes, product materials, and defect types, this plan provides the following testing station configurations

To meet the testing requirements. The design table for the testing station is shown below.

Workstation name | detection defect type | configuration |

| Printing hot stamping detection station | Printing hot stamping defect detection: Such as incomplete graphics and text, light printing, missing printing, heavy ink, stains, surface stains, color deviation Offset printing, flying ink, mosquitoes, paste, ink pulling, foreign objects, incomplete hot stamping, hot stamping deviation Position, etc Variable information detection: Real time recognition and detection of variable information, and comparison with source code files to detect duplicate and missing codes Defects such as incorrect codes and unrecognizable codes; Variable information printing quality defects, such as white lines White spots, ink leakage, offset printing, missed printing, etc | Camera: 1 8K high-speed color camera Dalsa Light source: 1 set of tunnel light source |

Based on the testing requirements of a maximum product width of 470mm and a maximum testing speed of 200m/min, the following testing solutions are provided:

1) Maximum detection speed: 200m/min;

Adopting an 8K high-speed color line array camera combined with a high-speed image acquisition card to meet the speed requirements of printing production.

2) Detection width: 470mm; Meet the detection requirements of a maximum width of 450mm and leave redundancy;

3) Applicable testing materials: white cardboard, copperplate paper, gold and silver cardboard, laser cardboard, labels, plastic film, transparent and

Translucent materials, etc;

4) Image acquisition resolution: 0.057mm × 0.111mm;

5) Real time recognition and detection of variable information, and comparison with source code files to detect defects such as duplicate codes, missing codes, incorrect codes, and unrecognizable codes; Variable information printing quality defects, such as white lines, white spots, ink leakage, offset printing, and missed printing.

6) Variable information detection type:

a) Numerical number;

b) One dimensional code: Code128、ITF25、EAN13、Code39、EAN8、UPCA、UPCE、UCC/EAN-128

Common formats;

c) QR codes: QR, DM, PDF417, etc.

7) Minimum point defect size detected: 0.10mm2 (contrast ≥ 20DN);

8) Detecting the minimum linear defect size: width ≥ 0.10mm, length ≥ 5mm (contrast ≥ 20DN);

9) Offset detection accuracy for overprinting: ± 0.10mm.

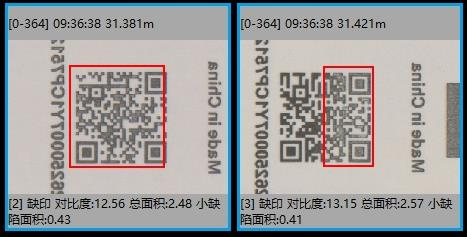

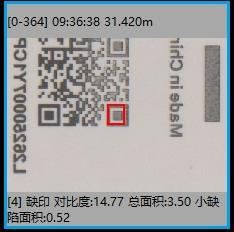

3. Description of defect alarm function

After the online printing quality inspection system detects defects, it provides sound and light alarms, displays defect images, and records defect information

There are three defect handling methods, including database processing.

1) Sound and light alarm

Once defects are discovered, the system will provide real-time sound and light alarms to remind machine personnel to adjust the printing equipment to avoid any issues

A large amount of waste.

2) Real time display of defect images

Real time viewing of defect images is available on the main interface of the detection system software; And indicate the specific location of the defect; defect image

It can be enlarged or reduced as needed, and the defect list supports automatic refreshing of the list with a "scrolling display" function.

3) Record defect information to the database and generate defect detection record reports

The defect detection records are stored in the database and can be browsed and queried through defect query software.

The defect detection record can also be used for subsequent defect removal.

Automatic Web Inspection System for Printing – Compatible Machines

An Automatic Web Inspection System for Printing is designed to provide real-time defect detection, print quality monitoring, and production efficiency improvement. It can be seamlessly integrated into a wide range of printing and converting machines, including:

Flexographic Printing Machines (Flexo Presses) – Ideal for narrow web, mid web, and wide web label printing, ensuring accurate color registration and defect-free labels.

Rotogravure Printing Machines – Perfect for flexible packaging and high-volume printing, detecting streaks, pinholes, and misregistration at high speed.

Offset Printing Machines – Applied in sheet-fed or web offset presses to maintain sharp image quality and prevent costly reprints.

Digital Printing Machines – Supports high-resolution digital label and packaging printers, enhancing consistency in short-run, high-speed production.

Label Printing Machines – Ensures barcodes, QR codes, and fine text remain readable, preventing defective labels from reaching the market.

Packaging Printing Machines – Works with film, foil, and laminated materials, widely used in food, pharma, and industrial packaging.

Coating and Laminating Machines – Detects surface coating issues, wrinkles, or bubbles to maintain uniform quality.

Slitting and Rewinding Machines – Enables defect flagging and precise roll management during finishing processes.

✅ With its compatibility across flexo, gravure, offset, digital, label, and packaging printing machines, the Automatic Web Inspection System for Printing is a critical solution for industries that demand 100% defect detection, color consistency, and production reliability