Bag Making Machines Explained: A Simple Guide to Types & Uses

Welcome to the world of bag making! If you're new to the industry, understanding which bag making machine can produce which type of bag is crucial for your understanding. This guide will detail the most common bag types and the machines specifically designed to produce them, helping you make the right choice and identify the bag making machine you're looking for right from the start.

1. High-Production "Workhorse"

From supermarkets to retail stores, you can see rolls of garbage and food bags, with or without paper cores. These bags come in various shapes, including flat bags and T-shirt bags, which are so named for their distinctive shape.

All of these bags can be made using a roll-to-roll flat bag making machine.

Flat Bag Making Machine

This is one of the most common plastic bag making machines.

It works by folding a flat tube of plastic film, creating a bottom seal, and then perforating or cutting the individual bags.

These machines are known for their high production speeds, making them ideal for large-volume orders.

2. Modern Shelf Star

These bags, with their gusseted bottom, are known as doypacks because they stand upright on the shelf without external support. They are ideal for displaying a wide range of products, from coffee to pet food.

Stand-Up Pouch Making Machine

This is a more advanced bag-making machine.

It can create complex bag structures, including gusseted bottoms, and often features a zipper for resealable closures.

These machines are versatile and can handle a variety of materials, including laminated films, to better protect the packaged product.

3.Bags with Zippers

These bags are commonly used for food storage and frozen foods and feature a resealable zipper.

Zipper Bag Making Machine

This specialized automatic bag-making machine integrates the zipper tape into the bag during the production process.

It precisely attaches the zipper, creating a clean, secure seal that ensures the bag can be opened and closed repeatedly.

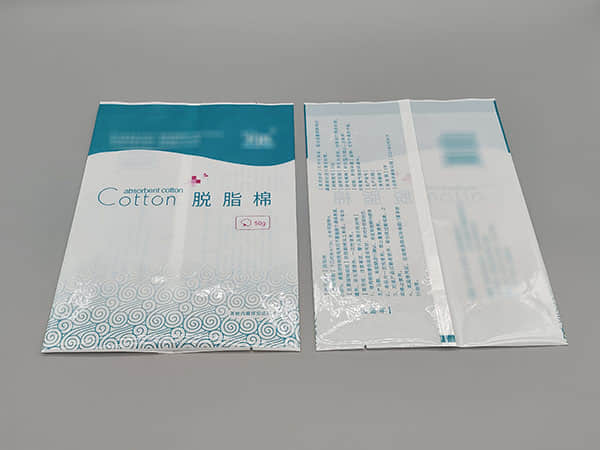

4. Simple Flat Bag with Three-Side Seal

Three-side-seal bags are a common packaging method used in supermarkets for snack foods, rice, tea, facial masks, and more. They are the simplest and most common bag type. They are sealed on three sides and open on one side, leaving only one opening for the user to fill the product.

Three-Side-Seal Bag Making Machine

This machine is efficient and easy to operate.

It creates bags by sealing on three sides (two sides and the top).

This is an excellent bag-making machine for businesses starting out with simple packaging needs.

5. Center-Seal Bags

Center-seal bags offer superior seal strength and sealing. Back-seal bags, with their seal located on the back, offer greater pressure resistance on both sides, significantly reducing the likelihood of packaging damage and better protecting product freshness and quality.

Compared to other bag types, center-seal bags utilize a hidden longitudinal seal on the back, which maximizes the integrity of the front packaging design. This allows for a variety of attractive designs and text, attracting consumers' attention and enhancing the product's market value.

Their inherent moisture-proof and waterproof properties make back-seal bags widely applicable, primarily for product packaging such as pharmaceuticals, cosmetics, food, and frozen foods.

Center Seal Bag Making Machine

This flexible packaging machine creates bags with a distinctive back seal.

It's highly efficient and can handle various packaging materials.

Ideal for businesses needing versatile packaging solutions for different products.

6. Pet Waste Bags

Small, durable bags used for pet cleanup, typically mounted on roll dispensers.

Pet Waste Bag Making Machine

A specialized type of flat bag making machine optimized for small-size production.

Creates bags on continuous rolls with easy tear-off perforations.

Focuses on high-volume output with material efficiency.

7. Fruit Protection Bags

Paper cover bags used to protect growing fruit from pests, diseases, and environmental damage.

Fruit Protection paper Bag Making Machine

Equipment specifically designed for paper fruit bagging.

Can produce simple open-mouth bags with precise dimensions suitable for a variety of fruits.

Often includes an added protective coating or wire closure.

8. Microwave Popcorn Bags: Specialty Food Packaging

Multi-layer bags with a special heat-resistant coating and bursting mechanism.

Microwave Popcorn Bag Making Machine

Advanced specialty bag-making equipment with precision coating.

Creates a unique folding structure for efficient popping of the kernels.

Capable of handling heat-resistant materials and food-safe coatings.

9. Drawstring Trash Bags

Large bags with an integrated drawstring for easy tying and carrying.

Drawstring Bag Making Machine

Complex bag-making system with integrated drawstring application.

Provides a channel for the drawstring to ensure smooth operation.

Can handle thicker materials, ensuring strength and durability.

10. Square-Bottom Paper Bags

Commonly used for shopping bags and packaging baked goods, flour, or high-end gifts, these bags feature a flat, rectangular bottom for durability.

Square-Bottom Paper Bag Making Machine

This machine is designed specifically for paper or craft materials.

It precisely folds and bonds paper to create a structured bottom, resulting in a durable and sustainable packaging option.

————————————————————

How to Choose the Ideal Bag Making Machine

Choosing the right machine depends on your key business questions:

What type of bag do my customers need? (This is your most important question!)

What material will I use? (Plastic film, laminated film, or paper?)

How many bags do I need to produce per day?

Confused? We can help!

Understanding the different types of bag making machines is the first step to growing your packaging business. [Contact our experts now] for a free consultation to find the perfect machine for your products and budget.