Top 5 Paper Take Away Food Box Making Machines for Disposable Container & Tray Production

Explore the Best Paper Take Away Box Making Machines from Ruian Zhongfa Machinery Co., Ltd.

With over 15 years of expertise in the food packaging machinery industry, Ruian Zhongfa Machinery Co., Ltd. specializes in high-performance paper lunch box making machines that help manufacturers boost efficiency and meet diverse packaging demands.

Our machines are engineered to produce a wide range of paper food containers—from rectangular to square, single to multi-compartment—across different materials such as kraft paper, PE-coated paper, and biodegradable board. Whether you're producing standard takeaway lunch boxes or customized eco-friendly packaging, we have a solution for every need.

In this guide, we’ll walk you through 5 of our most popular paper take away box making machine models to help you select the right one for your production line.

Video:

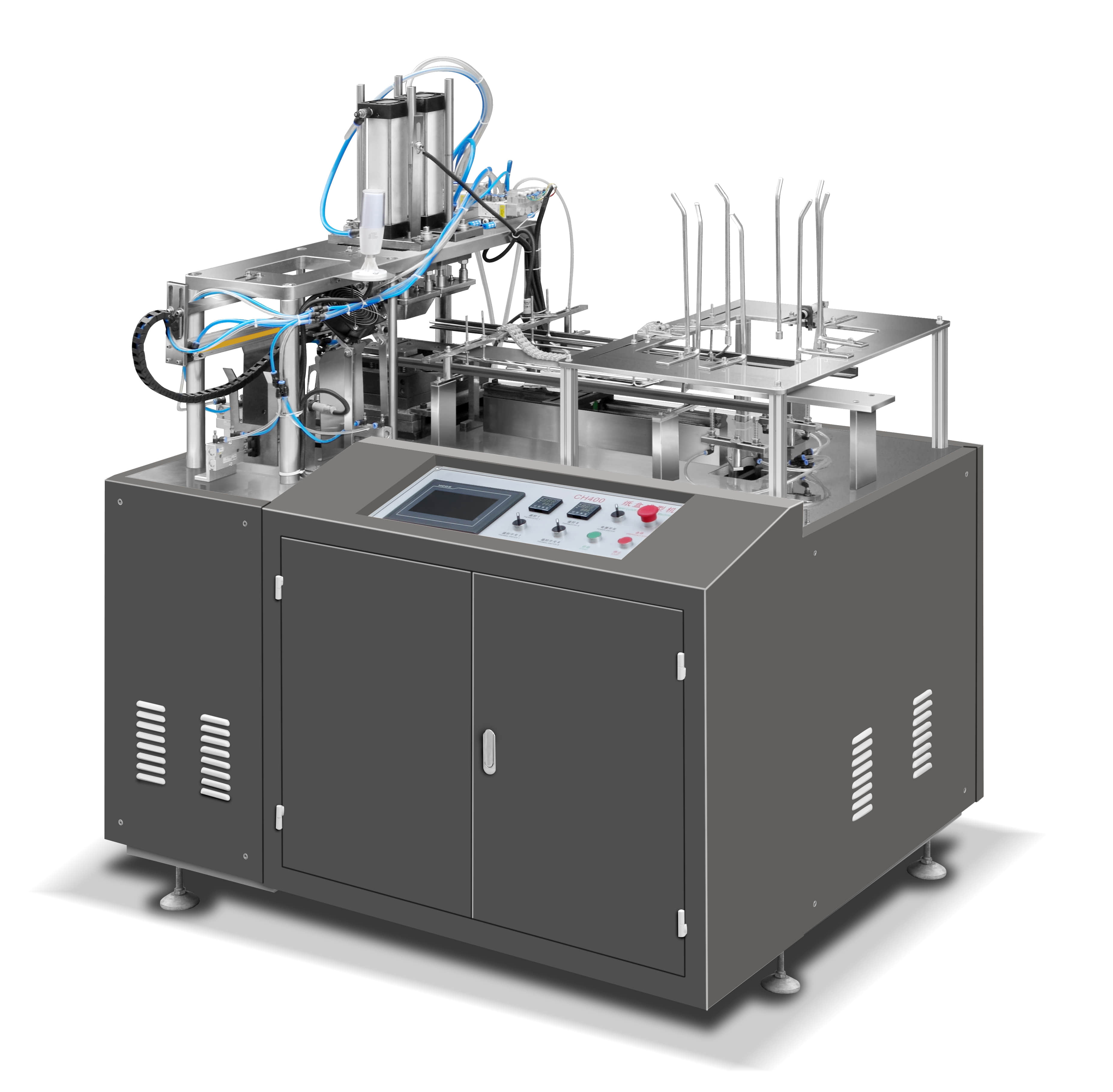

ZF-400: Specialized in the production of paper rice packaging boxes

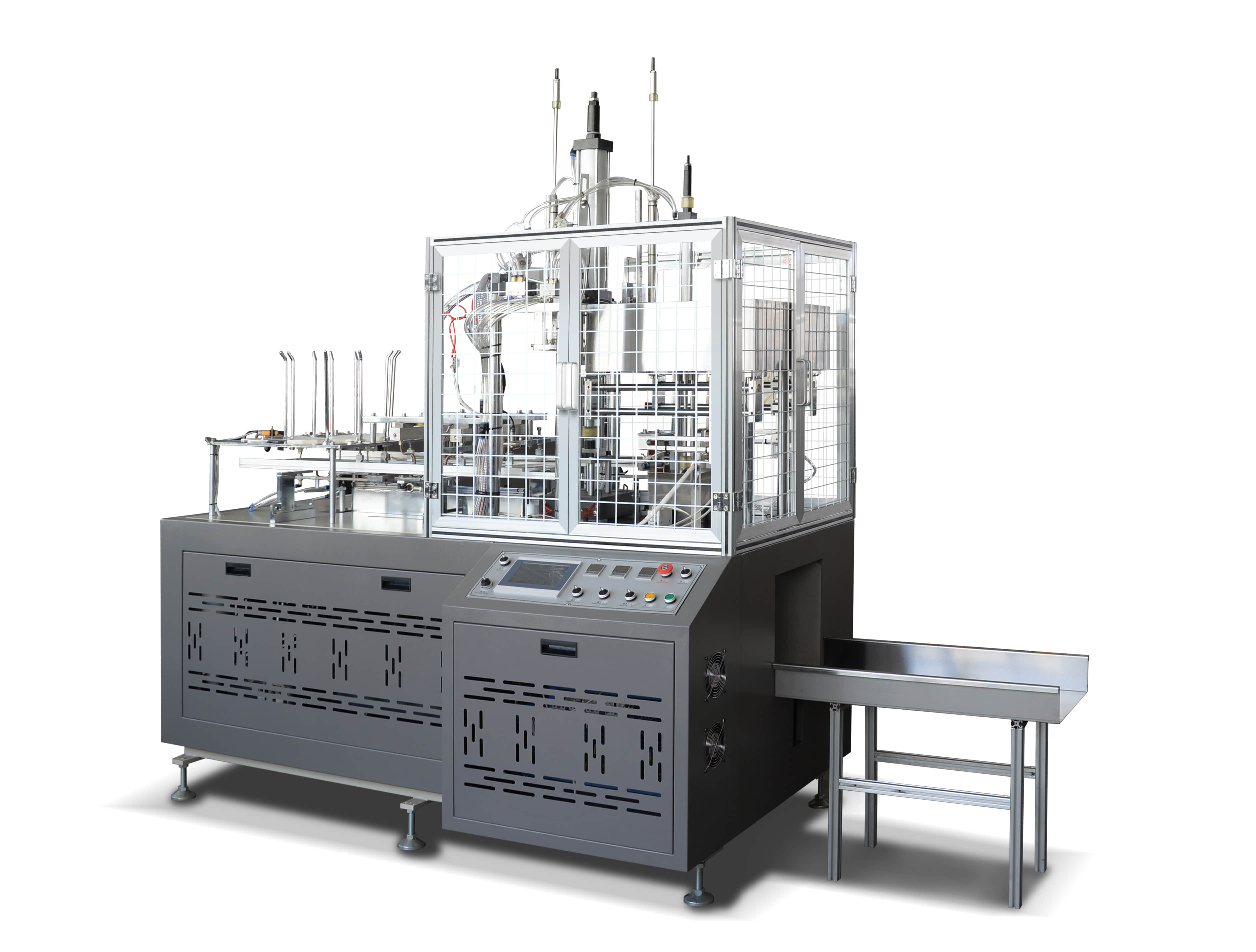

ZF-B: Efficient production machine of single-grid/double-grid paper lunch boxes

ZF-T2: Dual-channel high-speed production of single-grid lunch boxes

ZF-DG: Professional manufacturing machine for multi-grid lunch boxes

ZF-800Plus: High-speed production of hamburger boxes and French fries boxes

Which machine is best for making standard takeout rice boxes?

The ZF-400 model specializes in producing the square containers commonly used for rice and noodle dishes across Asia. With a working speed of 30-45 boxes per minute, it's perfect for restaurants needing consistent 400×400mm containers.

The machine handles 200-400g/m² PE-coated paper - the ideal weight for sturdy yet cost-effective rice boxes that won't leak or become soggy.

Applicable scenarios:

Fast food restaurant rice box

Takeaway lunch box

Disposable environmentally friendly lunch box

I need to produce single or dual-compartment food boxes – which machine offers flexibility?

For businesses needing flexibility, the ZF-B model stands out. It effortlessly switches between single and dual-compartment production, accommodating everything from simple noodle boxes to divided meal containers with separate rice and entree sections.

Its 600×550mm maximum size handles most standard takeout portions while maintaining an efficient 30-50 cycles per minute speed.

Applicable scenarios:

Chinese fast food compartment lunch box

Western salad box

Takeaway compartment box

I need higher efficiency to produce single-compartment lunch boxes. Is there an upgraded version of the machine?

The ZF-T2's dual-channel system revolutionizes single-compartment production. By simultaneously forming two boxes instead of one, this advanced version of the ZF-B boosts output by 30%, producing 40-50 boxes per minute. Food vendors experiencing growing demand will appreciate how this machine maintains quality while dramatically increasing capacity without requiring additional floor space.

Applicable scenarios:

Batch production of single-grid food lunch boxes

Factories that need to increase production

Fast food chain companies

What machine should I choose for meal prep containers with multiple sections?

The ZF-DG model solves the unique challenges of multi-compartment containers. Specializing in 2-4 section meal trays, it's ideal for:

- Healthy meal delivery services

- School lunch programs

- Cafeterias needing rice+main+side configurations

While slightly slower at 20-30 cycles/minute (due to complex forming), its precision engineering ensures clean divisions between sections - no leaking sauces between compartments.

Applicable scenarios:

Multi-dish takeaway box

School/corporate canteen lunch box

Pre-prepared food packaging box

Which machine delivers the fastest production for fast food packaging?

When speed is critical for burger boxes, fry containers, and fried chicken packaging, the ZF-800Plus dominates with astonishing 50-300 pieces per minute output. Key features include:

- Specialized forming for angled fast food containers

- Handles thicker 1.5mm corrugated material

- Accommodates various sizes (100-650mm length)

Quick-service restaurants and large-scale caterers benefit most from this high-volume specialist that keeps pace with busy service periods.

Applicable scenarios:

Hamburger boxes, French fries boxes

Fried chicken boxes

Fast food chain mass production

Bottom Line:

We hope this article helps you solve your paper lunch box machine questions and understand the uses of different paper lunch box machine models, so as to ensure that the equipment you invest in truly meets the needs of your business.

Why choose our paper lunch box making machine?

✅ High capacity: meet the needs of production of different scales

✅ Flexible adaptation: support a variety of sizes and materials

✅ Energy-saving and efficient: reduce production costs

✅ Global service: provide installation, training, and after-sales support

You can customize the machine to produce your paper lunch box according to your needs.

Consult now to get the most suitable paper lunch box making machine solution for you!