Label Quality Inspection: Essential Technology for Zero-Defect Label Production

What are self-adhesive labels?

Self-adhesive labels are a common labeling product, widely used on products across various industries and fields. They are easy to apply and remove, leaving no adhesive stains, making them popular with consumers. Therefore, the printing quality of self-adhesive labels is a key concern for manufacturers and suppliers, ensuring they meet stringent quality standards.

Why label quality inspection so important?

Common printing quality issues with self-adhesive labels include missing text, missing prints, smudges, overprint deviation, color difference, fundamental defects, gold stamp defects, cold stamp defects, overflow, scratches, and bubbles. These issues can affect the product image and consumer perception of the product, as well as impact the credibility of the partnership with the product partner.

Therefore, quality inspection of final printed labels is extremely important. Traditionally, manufacturers relied on experienced human inspectors to ensure label quality. However, with the shift to smaller fonts (as fine as 5.5pt) and zero-tolerance policies in industries like pharmaceuticals, the limitations of human inspection have become apparent. Inefficient inspections and high rejection rates are common, and these inevitable oversights can lead to losses for manufacturers. These can include regulatory non-compliance (e.g., FDA, EU Packaging Directive), incorrect labeling, and ambiguous product information, leading to product recalls, batch rejections, material waste, contract terminations, and even reputational damage.

What is label quality inspection?

In today's increasingly demanding label printing, even minor defects can trigger costly recalls. Manual inspections are no longer sufficient for manufacturers' production needs, and they are turning to machines equipped with advanced vision inspection systems to detect defects in printed labels.

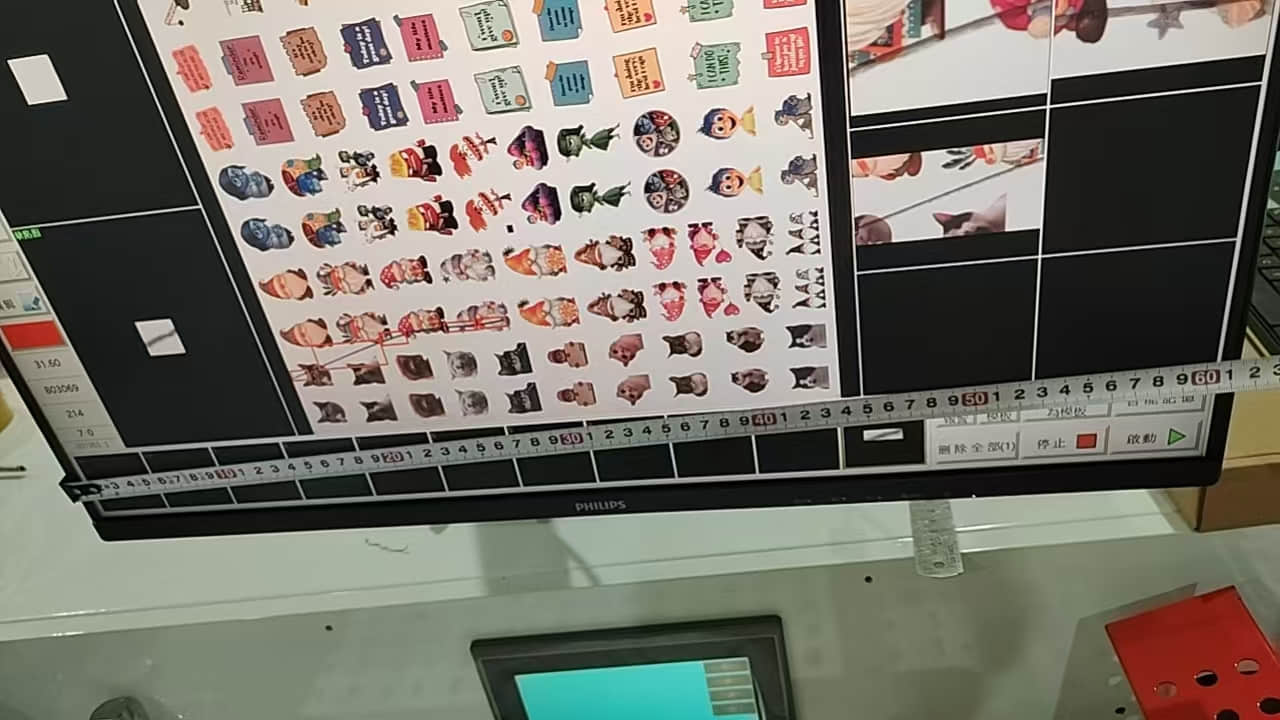

Label quality inspection machine is a post-printing device suitable for narrow-web paper slitting and rewinding. Its label inspection system includes a high-speed camera, industrial-grade lens, LED light source, signal interaction, image processing software, and a mechanical support. It detects defective self-adhesive labels before slitting and automatically stops the machine, ensuring the quality of the final printed labels. The machine also automatically measures meters, counts, and sets lengths and quantities.

Label quality inspection machines are widely used in printing processes such as food, daily chemical, and electrical labels to automatically detect defects in printed labels.Click to get our recommended professional automatic label inspection machine

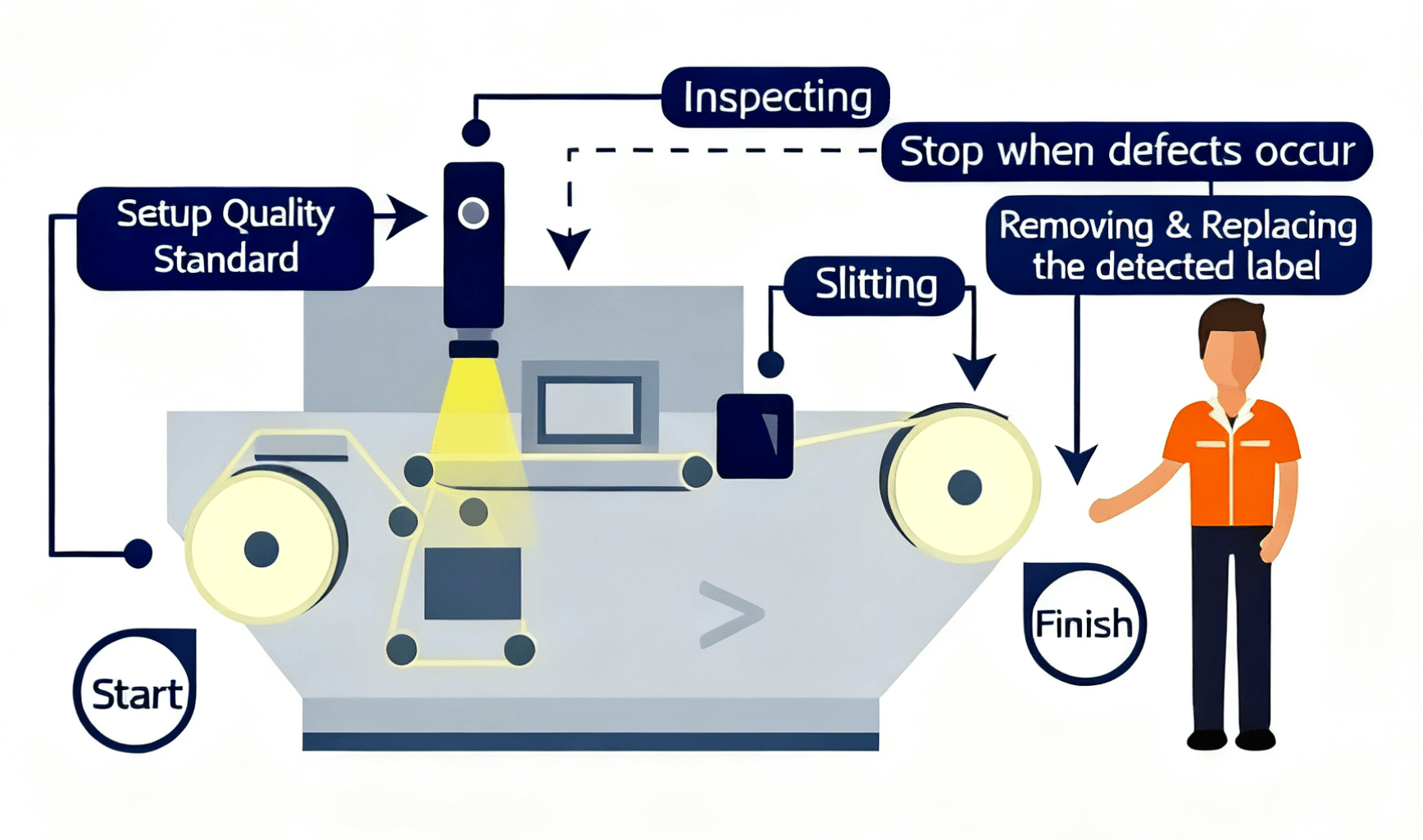

How Label Inspection Machines Work?

1. Image Capture: A high-resolution camera scans the label at high speed.

2. Defect Detection: An AI algorithm compares the label to a preset standard, flagging deviations in text, graphics, or color.

3. Automatic Stop: When a defect is detected, the machine stops and locates the defective label for manual removal.

4. Rewinding and Slitting: After inspection, the labels are rewound or slit into rolls for packaging.

Comparing Manual Inspection and Automation

Challenges faced by manual inspectors:

- Errors caused by fatigue during long shifts.

- Inability to detect micron-level defects.

- Inconsistent color differences under different lighting conditions.

Advantages of automatic label inspection systems:

- Inspection accuracy of up to 99.9%, capable of detecting defects as small as 0.1 mm, and color difference accuracy of ΔE ≤ 1.

- Inspection speeds of up to 80 m/min, surpassing manual inspection.

- Slitting speeds of up to 300 m/min.

- Real-time data logging for traceability and compliance reporting.

Industries that rely on label quality inspection

- Pharmaceuticals: Ensure dosage clarity, regulatory compliance, and patient safety.

- Food and beverages: Prevent allergen or ingredient mislabeling.

- Cosmetics: Maintain brand consistency and adhere to ingredient lists.

Elevate Your Label Quality with Automated Inspection

In today’s competitive manufacturing landscape, automatic label quality inspection machine is no longer a luxury—it’s a necessity. The transition from error-prone manual checks to precision-driven automated systems marks a critical evolution in ensuring product safety, regulatory compliance, and brand integrity. Whether you operate in pharmaceuticals, food packaging, cosmetics, or other highly regulated sectors, investing in advanced label inspection technology is essential to mitigate risks such as recalls, reputational damage, and non-compliance penalties.

Click to get our recommended professional automatic label inspection machine